|

|

|

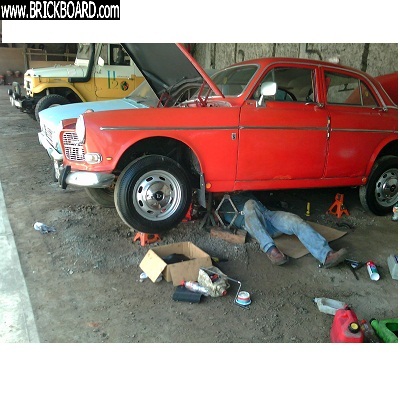

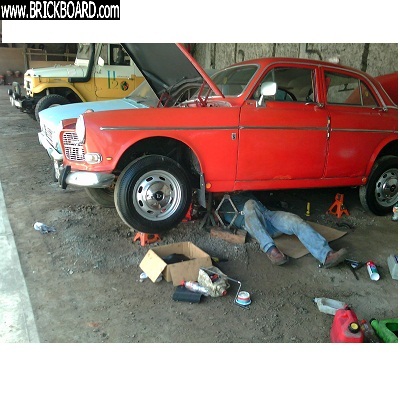

1966 122 B18D with glass bowl (Canadian) fuel pump.

Were there different thickness phenolic spacers used with different fuel pumps?

My '66 came to me from the original owner with the glass bowl type fuel pump. The pump seemed to be working okay but there was a bit of oil seepage coming from the underside of the pump area. Last week I put new gaskets on both sides of the spacer but the oil leakage continued.

The car had also developed a habit of needing a lot of cranking to get started in the morning. Once started she runs fine all day and will start right up on the way home from work after sitting for eight hours. I figured that the fuel pump might have a very small hole in the diaphragm that might allow fuel pressure to drop at the carbs overnight.

Sunday a spare Pierburg pump was installed. In mating the new(er) pump to the phenolic spacer, it became apparent that the spacer was cupped. So _that's_ why there was oil leaking down there! I used some high temp RTV sealant and carefully snugged the two mounting bolts but a dreaded cracking sound came to my ears just before the bolts were good and tight.

My 544 is no longer available for reference but I could have sworn that the spacer on the 544 was a bit thicker than the warped one on the 122. The 544 had a Pierburg pump the entire time it was in my possession.

For now, the RTV is sealing the crack just fine and the spacer should be okay until there is any reason to remove it. My plan is to rebuild the glass bowl fuel pump. Are there different thickness spacers between the two types of fuel pumps?

Thanks much,

Joe M in WV

|

|

|

|

|

The spacers are all the same, the pumps themselves can leak oil.

Regards

Pete

|

|

|

|

|

Thanks for the confirmation on spacer size.

It was hard to tell where the oil was coming from since it gets blown around so much down there while driving. The spacer was cupped enough to allow a good 1/16" of daylight when mated to the Pierburg pump so I suspect that the oil was making its way between the pump and spacer.

Where is the usual point for the glass bowl fuel pump to leak oil if the spacer and gaskets are good?

Joe M

|

|

|

|

|

In my experience, the cam repeatedly pounding on the lever actually dishes the aluminum casting of the pump. I've put a straightedge across the pump and was amazed at the amount of deformation. I took a file to it to make it flat, though, over time it will dish again. or break.

|

|

|

|

|

Danny;

Do you mean the flat face of the pump housing which contacts (or should contact)the spacer? WOW! That's pretty incredible!

I wont argue with what you saw, but I find your explanation of what caused the "dishing" pretty hard to believe...in the first place, the cam is in constant contact, accelerating the lever relatively slowly as the eccentric comes around (I would only call it "pounding" if contact was lost, and the lever actuation was more of a step function), secondly, the base of the casting is quite massive and strong, so I suspect it would crack before bending...could it have been some sort of casting warpage while cooling maybe?

...ther's got to be another explanation!

Cheers

|

|

|

|

|

I'll bet others have had this experience as well. Oil weeping at the fuel pump. disconnect, remove pump, clean all 4 surfaces - block, pump and spacer, gasket seal all 4 surfaces and get the gaskets in place and the screws in place, tighten up. And not too much later - leaking again.

I figure it happened because the bolts weren't tightened enough, and the spacer thickness allowed a little looseness to allow the pump to rock (up and down), eventually pulling the aluminum or pot metal bolt hole tabs in enough for the gasket(s) to separate from the spacer/pump/block et voila! the oil she drips!

I remember seeing at least 1/32 of daylight between a straight edge and pump body. check out an old pump if you have one i doubt it'll be flat.

|

|

|

|

Danny,

Happy New Year!

Just so you don't feel all alone out there: You are VERY right! - the pumps DO tend to build a slight deformation and thereof the oilleak. File it down as you describe! (If a lot - use two original gaskets (and that's, 3 in all...))

--

/Soren

|

|

|

|

|

I just placed a straight edge along all sides of the mating flange of the glass bowl pump housing. There does not appear to be any warpage. This is not too surprising as the flange is almost 3/8" thick. I suspect that the mounting flange on the engine isn't likely to be warped either :-).

This leaves the spacer as the likely misfit. I was surprised at the (apparent) cupping of the phonolic spacer. Those don't appear to be very flexible either. Perhaps it was run for some time with a less than secure fuel pump mounting bolt.

The Pierburg pump could have had a warped mounting flange . . . I probably won't check it until the A.C. pump is ready to be reinstalled though.

Thanks for all the feedback,

Joe M in WV

|

|

|

|

|

It's difficult to get a decent reading without dismantling the pump so that you can put a straightedge across from bolt hole to bolt hole.

It's also possible that a loose mounting bolt would allow the pump to rock enough to leak,

Is it possible that the shaft which the lever pivots on penetrates the pump body and could allow oil to leak? Naaahhh.

|

|

|

|

|

Yeah, I pulled my old pump and installed a new one with new gaskets due to a similar reason. Looking at the old pump, it did look a litte warped. Then again, the new one did also. I suspected that the leakage in the old pump face was due to the pump bolts being over-tightened to stop the loss.

I have not put as many miles on the Amazon since the switch (due to other issues), so I can't say if it's helped. I do have a lot less overall leakage than before, but I replaced A LOT of seals and gaskets - not just the pump.

I also recall that the different sized spacers were for the different sized pump levers. There were at least 3 different pumps for the Amazons

--

1967 P220 Amazon, 1972 145S, 1976 245 DL, 1983 245 DL, 1986 745 GLE, 1990 745 GL, 1995 945....

You mean to tell me that Volvo makes cars that are *NOT* Wagons?!?

|

|

|

|

|

They leak underneath, where the lever pivots.

Regards

Pete

|

|

|

|

|

Using HS6 carbs?

Float bowls should be full and they contain enough gas to run several blocks

without having to pump any. Maybe they are leaking and so you have to pump

fuel into them to start.

Might have a pinhole somewhere going INTO the pump so it doesn't suck hard

enough.

Far as I know the spacers are pretty much alike.

--

George Downs Bartlesville, Heart of the USA!

|

|

|

|

|

Abbey still needed a couple of 10 second cranks from the starter to fire up this morning so the problem didn't follow the pump. I'm going to check the choke cable at both ends to make sure that there isn't any slippage causing partial choke engagement.

If that don't fix it, then I'll check the float chambers next chance that comes up when it can sit for 24 hours or so.

Thanks as always,

Joe M

|

|

|

|

|

Usually if you have spark and fuel it will start pretty quick.

It will only take a minute or 2 to pop the float chamber lid to see

if there is (any) fuel in there. Doesn't take much.

How fast it cranks makes a difference. If your charging system is doing

its job (13.5-14v) and your battery is strong it makes a big difference.

--

George Downs Bartlesville, Heart of the USA!

|

|

|

|

Two months ago I has the same delay at morning "cold" start. After change the hose and filter between pump and the tube from the tank (hose with small and fine cracks from old - the reason for the change- and filter is cheap). Now my car starts on the first or second short crank.

Btw, my carb is a stromberg, and is usual to lost the petrol on it due evaporation after a day with the engine off (here is summer, hot). My filter now is a "glass of water" type (used on old fiats and now in toyotas), but made on plastic. It store a small quantity of petrol and it also help on start.

--

Joaquin / Rojo 121 / Lima, Peru

|

|

|

|

|

Thanks for the reminder to change the fuel filter.

Several hoses were changed with the fuel pump. The old hoses didn't want to loosen their grip on the pump. A pair of large electricians dykes cut those old hoses off real quick and easy. It might be a good idea to just change out the rest of 'em next time the hood is open.

Best regards,

Joe M in WV

|

|

|

|

|

Haven't seen this mentioned as a source for oil leaks from around the fuel pump. The phenolic (plastic) spacer itself will develop a hairline crack on the bottom, at around "5:30". This can come from excessive, or uneven tightening, sometimes from too much sealing "stuff". Take the culprit off, remove all gasket material, silicon, shellac, grease, etc. and try to slightly pry it apart at the bottom of the slot. If it's cracked, then it's leaking for sure. You might buy some time by superglueing it, and gently putting it back in place, but a new one is cheap, and fool proof.

Also, if you have the older style glass bowl type, make triple sure that the rubber seal under the bowl is really doing its job. They get brittle, but won't really suck air (instead of fuel) unless they are under load. Hope this helps.

|

|

|

|

|