|

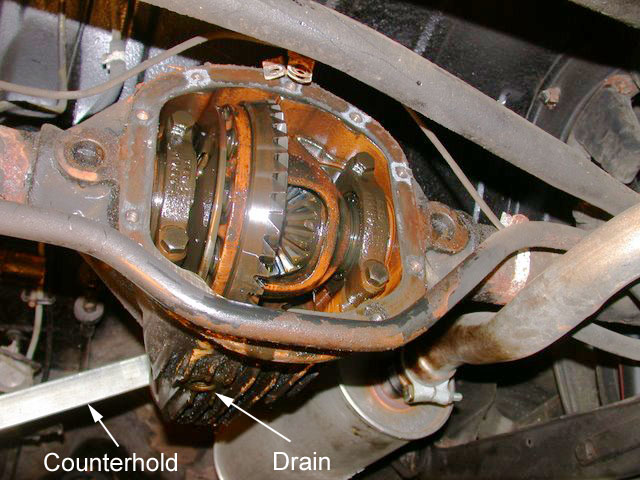

I've been working on Volvos for a long time, and I HAVE jacked up the rear via the diff. many times in the past, but for some reason it seems... well, kind of unnatural this time. maybe I'm getting careful in my old age, or just way overthinking it, or maybe the 1993 diff is somehow differently shaped??

I have a little craftsman 2.5 ton floor jack, the kind with the little "castle" cup on the top. Enough about me, here are some crappy drawings of two different jack placements in relation to the diff (side view). Tell me which one you use, please.

Version 1: the jack hits the diff dead center (l-r), centered front to back on the ridge on the differential's cast iron casing.

Pros: the ridge keeps the jack locked there...

Cons: seems weird to support that much weight on a narrow lip like that.

Version 2: the jack is slightly fore of the ridge on the bottom of the diff, dead center L-R).

Pros: Seems like a better surface to jack on than that ridge

Cons: it's angled (back lower than the front), so the jack doesn't hit it evenly. Not much space side to side for the jack cup to do it's thing at all. Tried setting it up w/a chunk of 2x4 on the cup and that slipped around all over the place.

Let me know what you think, thanks!

|