|

|

|

Noticed a hot front wheel after a drive. The caliper on that side had a sticky piston. Replaced both front calipers, bled; have good pedal again. But brake-failure light came on.*

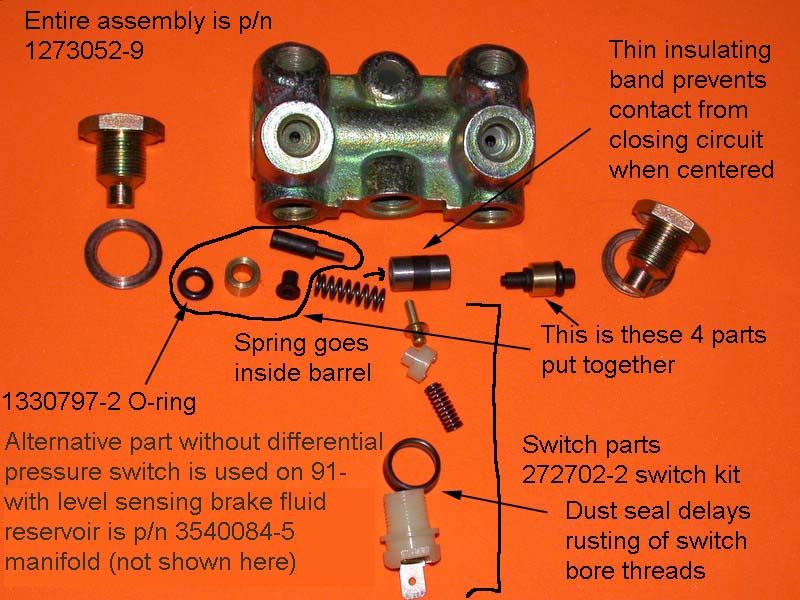

Brickboard instructions suggest removing the switch from the valve/junction block and re-centering the valve with eg. a small screwdriver/pick. I removed the switch, spring, and nylon insert. It wasn't clear what to do so I disassembled a spare block - 1st time I've had one apart. Comments/questions:

Operation: If pressure is unequal, the valve slides & grounds the switch which turns the failure light on. The center of the slide has a plastic insulating band so in the correct position there is no ground - correct?

When you remove the switch and reach in with a pick, you don't know which way to move the valve - left or right.

If the valve is sticky, you risk scoring the valve and/or breaking the plastic insulating band. (I did both of these deliberately on the spare valve block). If you break the plastic band, switch is grounded even with the valve centered.

If the valve is sticky, you could remove the block, disassemble, clean gently with fine steel wool, and reuse. But if the valve is that sticky from moisture in old brake fluid, it's probably time for a new block and valve.

This is the 1st time I've had a brake-failure light that didn't reset itself.

---------------------

*Bleeding method: I use, until I get good pedal, in this order: 1) vacuum to draw out air and fluid; 2) pressure; 3) pumping the pedal, holding it down (assistant or spring-loaded stick), and releasing the bleeder.

I think (3) caused the problem via too much pedal travel - even though I had a wooden block under the pedal. The master-cylinder is < 1 year old.

--

240 drivers / parts cars - JH, Ohio

|

|

|

|

How thick was the plastic band?

--

Art Benstein near Baltimore

When an actress saw her first strands of gray hair she thought she'd dye.

|

|

|

|

|

The plastic band (in the spare) is thin: microns thick I guess. Black, hard plastic/nylon.

--

240 drivers / parts cars - JH, Ohio

|

|

|

|

|

Thanks Art, great pics.

I took apart a 2nd used spare unit today - gently to examine more closely. I found that the band was worn through on the switch side. Shiny metal was visible when I looked in through the cleaned switch opening.

There were small shreds of the nylon band that came out with the sleeve. So

1. Perhaps the band can be worn through by the switch but I'd bet that it's more-often ruined by someone re-centering a stuck sleeve.

2. Some folks skip requisite brake-fluid replacement: don't know to do it or on a small repair the mechanic says "we can flush the system but we risk breaking bleeder screws ... plan on 4 calipers, some lines, a lot of labor".

So you end ep with a corroded/sludged sleeve that's hard to re-center.

Two questions:

1. Your diagram says "alternate part ... 91-up". They mean that ABS cars don't have this mechanism, correct? (Some 1991 are non-ABS).

2. What's the effect if you remove the valves and sleeve ie. does the block have any braking (vs warning) function?

2a. I thought until recently that this junction/octopus block had a proportioning function but in reading here I learned that proportioning is done via the reduction valves on the rear axle.

(It's called a "proportioning valve" on eEuro parts).

2b. I'm not suggesting that we could gut the block. And I think that the sliding sleeve would have to remain: it is also a seal - without it pressure would blow our the nylon switch.

--

240 drivers / parts cars - JH, Ohio

|

|

|

|

2. Some folks skip requisite brake-fluid replacement: don't know to do it or on a small repair the mechanic says "we can flush the system but we risk breaking bleeder screws ... plan on 4 calipers, some lines, a lot of labor".

This is so true. I use the excuse myself. Deciding to bleed the system on one which is long overdue involves this one very real risk, breaking bleeder screws. So, before any commitment is made, we should visit all 8 valves with a rap and a tap to be sure they can all be unfrozen.

Two questions:

1. Your diagram says "alternate part ... 91-up". They mean that ABS cars don't have this mechanism, correct? (Some 1991 are non-ABS).

Correct. ABS cars do not have the differential pressure sensor, but use a more sensible float sensor in the reservoir.

But the NON-ABS 1991 is special. Its reservoir also uses the float sensor, but the manifold to distribute the brake lines is just strictly a manifold -- no communicating parts -- no moving parts. An excellent replacement for the old octopus, if combined with the special reservoir and float sensor. Make a promise not to scrap any non-ABS cars without snagging these items. You'll not be sorry.

2. What's the effect if you remove the valves and sleeve ie. does the block have any braking (vs warning) function?

If you pulled the shuttle out of the octopus, even if you could block the switch port against hydraulic pressure, you would no longer have two independent brake circuits, losing the redundancy advantage.

2a. I thought until recently that this junction/octopus block had a proportioning function but in reading here I learned that proportioning is done via the reduction valves on the rear axle.

(It's called a "proportioning valve" on eEuro parts).

Correct again. They reduce the braking of the rear calipers proportionately.

2b. I'm not suggesting that we could gut the block. And I think that the sliding sleeve would have to remain: it is also a seal - without it pressure would blow our the nylon switch.

Exactly right. That's what makes the non-ABS 91 block a good thing to have.

--

Art Benstein near Baltimore

People who live on that "New Car Smell" and have their Credit Score memorized better than their own birthday will ALWAYS say you're Crazy. -punk240 Tim

|

|

|

|

Anyone reading this, do yourself a favour and find a 1991 non-abs block (octopus). No moving parts, and you will never have to fool with this problem again. Not easy to find, took me several weeks of looking and calling around, but WELL worth the effort. just my .02

Scott in Dallas.....

|

|

|

|

|

Thanks for the thorough reply. Good info to have.

JH: 2. Some folks skip requisite brake-fluid replacement: don't know to do it or on a small repair the mechanic says "we can flush the system but we risk breaking bleeder screws ... plan on 4 calipers, some lines, a lot of labor".

AB: This is so true. I use the excuse myself. Deciding to bleed the system on one which is long overdue involves this one very real risk, breaking bleeder screws. So, before any commitment is made, we should visit all 8 valves with a rap and a tap to be sure they can all be unfrozen.

JH1: I'm guilty too on my own carts for the same reason - frozen bleeder screws. And my usual projects "Will you take a look at this 240 I just bought..." are always a challenge.

I just worked on one. Pedal became hard on the drive home and it turned out ~1/2 of the pistons were frozen. Then, I broke the flare fitting on two of the calipers when I tried to remove the lines - the threads stayed in. So 4 calipers, 2 rotors, pads, pins, a few lines, fluid .... expensive "deal".

I saw here a suggestion about heating, cooling with water, re-heating, .... repeat ... that's worked for me a couple of times this year. But on the larger (older?) bleeder screws.

AB: Correct. ABS cars do not have the differential pressure sensor, but use a more sensible float sensor in the reservoir.

But the NON-ABS 1991 is special. Its reservoir also uses the float sensor, but the manifold to distribute the brake lines is just strictly a manifold -- no communicating parts -- no moving parts. An excellent replacement for the old octopus, if combined with the special reservoir and float sensor. Make a promise not to scrap any non-ABS cars without snagging these items. You'll not be sorry.

JH1: Didn't know that. I have a non-ABS 1991 in the barn now waiting for the scrap price to go up. I think I've already pulled the brake system but I'll tag the master cyl & manifold.

--

240 drivers / parts cars - JH, Ohio

|

|

|

|

|

Very good pictures Art.

I had a problem like this many years ago. And it frustrated me.

The way I fixed it is by pressing strongly and rapidly the brake pedal just like if I were in an emergency braking situation on a highway. I did it many times in a row. The light went off confirming recentering of that contact pin. There is no need to remove the switch plug like in the older systems unless the system is realy jammed.

No doubt any weak part will show failure with this method but it is better in your driveway then have that occurance on the highway at 60 mph.

I assume these O-rings never move and are fudged in place.

|

|

|

|

Thank you for the compliment, Sir. I've been posting these same pics for a dozen years now and figured we were all tired of seeing them.

So far my experience does not include an actual brake failure -- meaning I've not had a car where the shuttle moved off center or had a reason to.

But the light has come on anyway in some occasions, and when it does, I cannot ignore it. The resistance I measure between contact and ground is not that of a metal contact, but a reading consistent with electrolysis like the load of a plating tank. Reversing the ohmmeter leads confirms this. The warning lamp is surprisingly well lighted through a bit of rusty, watery brake fluid seeping past those fudged-out O-rings.

Washing out where the switch lives is easy. Getting the nylon switch plug started past the rusty casting lip is one of those few things that might bring a smile to a person with a lift to work under.

--

Art Benstein near Baltimore

He who obtains has little. He who scatters has much. -Lao Tzu

|

|

|

|

|