|

|

|

Car is a 1980 242, with B21F engine, and K-Jet fuel injection. Experiencing an odd and intermittent idle issue. So odd and intermittent that at times I think I am imagining it. Every few to several months it seems the car seems to idle ether a bit too slow or too fast. I readjust the idle via the plastic idle adjustment screw on the throttle body. Then, all is fine for quite some time...until the next time I notice the idle is off. At times it seems I am backing the plastic screw out quite a bit in order to get the idle up to proper idle speed. All vacuum hoses are tight, seals around injectors are tight etc. Appreciate any ideas for further inspection, diagnosing or troubleshooting.

|

|

-

|

|

|

Thanks all for the guidance, and especially for pointing me in the direction of the auxiliary air valve. I went to clean it out, and in so doing noticed that the S-hose that connects from the top of the AAV to the intake manifold had become soft with age. It developed a crimp that severely reduced air flow. This was an aftermarket hose. I replaced with a genuine Volvo hose, which is of much thicker and rigid construction, and all seems much better now. Always gratifying and fun to receive a bit of outside knowledge to help explore the quirks of a 40-year-old car !!

|

|

-

|

|

|

It's the broadly intermittent sometimes staying high, sometimes staying low aspect of your idle issue that has me curious. Normally I don't comment much on K-Jet issues as that part of my brain has been left to atrophy in my LH world, but for some reason your idle issues are ringing bells. I had lots of idle issues with my B20F (similar to your B21F). I cracked open my Gerhardt Volvo Problem Solver book to see if that would help refresh my memory or if I'd added notes there (it was my K-Jet troubleshooting bible). Phil's good system explanation and comments also helped to refresh my thinking.

I started thinking about a sticky auxiliary air valve or one with a badly worn bi-metallic lever, but I'm not sure your symptoms match. Once the engine is fully warmed the auxiliary air valve should be mostly out of the equation unless the slide is somehow getting stuck at slightly different closed positions. In case this is the problem area, after the engine is fully warmed, tap on the valve to see if the valve moves and changes idle to indicate a sticky valve. You could also try sighting through and note the min opening slit size when the engine is fully warmed, like compared to a 1/8" dia drill bit. When the warm idle appears to have changed (too low or too high), sight through again to see if the min opening size is different.

Now I'm wondering if it's at the air flow plate. When the pivot gets badly worn, or the plate is loose or misadjusted, or there's a dirty throat, it could bind to the side or come to a different rest point at idle. I recall having a sudden change in idle I simple couldn't correct with the air bypass adjustments and the problem turned out to be at the plate. Again, try tapping on it to see if that notably changes idle or maybe open it up for a cleaning and inspection.

Once Mr. K-Jet (Art) reads this thread I'm sure he'll have more definitive ideas for you.

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

-

|

|

|

Thanks, Dave,

Looked at the auxiliary air valve, and when filly warmed up, it appears to be fully closed. I don't recall, but should it be a wee bit open when warm ? Currently with daytime ambient temps in the 80's and 90's, it is difficult to monitor how much it opens when "cold."

|

|

-

|

|

|

The only thing I can see in my aftermarket manuals is that it should be half-open at room temp (68 degF, 20 degC) going to fully closed within a few minutes of applying current to the bi-metallic lever or for a fully warmed (hot) engine, so that's what I'd shoot for when checking and adjusting. As long as you can compensate with the air bypass screw, it probably doesn't matter a whole lot if it's fully closed or a hair open on a fully warmed engine.

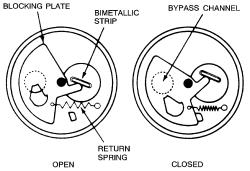

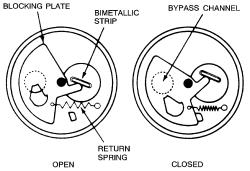

Further reading suggests the little return spring inside can get week with age. I suppose the bi-metallic lever could also suffer a bit from age. I recall using a drill bit shank as a gauge when adjusting the nut, something like a 1/4" bit at ambient (room) temperature, perhaps someone can confirm that adjustment. Add a bit of grunge or a wear groove in the bi-metallic lever and it could mean you're not getting a nice consistent closure when warm.

If tapping it causes the warm idle to change then I'd attempt a cleaning, like spraying in some penetrating oil or WD-40, rotating the plate to the side so you can work it in, followed by dipping it a number of times in a shallow solvent bath to rinse it clean, keeping the bi-metallic lever end pointed up and mostly out of the fluid, followed by shaking it out and compressed air to dry it.

Once, when worried that someone might have been playing with it ahead of me, I remember forcefully turning the electrical connector to rotate the bi-metallic lever back and forth a bit to make sure the lever was square to the little tab and allowing maximum closure, not that I'm suggesting you do that, just that turning the electrical connector will alter the lever orientation inside and could change behaviour for the worse. I actually pulled an old one apart to see what made it tick and after cleaning and adjustment kept it as a spare. You won't have to pull yours apart, I found a couple of images that may help you.

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

-

|

|

|

Thanks for the insights, comments and suggestions. Car is a US model with auto trans. I have had it since new. All injector seals and vacuum hoses are new and tight, so pretty sure no vacuum leaks. It does have the auxiliary air valve mounted to the valve cover, so I will check that out for function as well as any vacuum leaks I may have missed. Car also has an oxygen sensor which was replaced about 1 year ago.

|

|

-

|

|

|

Hi,

I still have my 1978 GT with the same but maybe less revised K Jet system.

The K system is all pretty much a mechanical except for the heating of the control pressure regulator and the auxiliary air valve mentioned.

That black “bypass air” knob on the throttle body was used to set or for just adjusting to the lowest rpm setting area while setting monoxide levels. It’s used with a Volvo exclusive dwell meter and combines with an emissions meter. A dwell meter is used to observe action of the frequency valve controlling mixtures, per the Oxygen sensor.

You could “technically” mess around with the fuel distributor using an Allen wrench through an access hole on the fuel distributor. It’s purpose was to rough the “plate or flap in” to get the engine into a tailpipe “cleaner emissions” range.

The knob is very limited in its capabilities for actual idle control but it allowed mechanics to be able getting a “fine” adjustment. The wrench adjusted the fulcrum coarsely.

The Lambda system uses an oxygen sensor that sends its signal to the ECU that operates a frequency valve via a small cube relay located on the left fender.

Now, as I remember that relay has two functions but I only remember one of them at the moment.

I believe it cannot stay on as it might run down the battery? Just cannot remember.

I do know It transfers power to the valve and if it doesn’t, the engine will not run worth crap!

You want to hear a buzzing sound anytime the engine is running or turning over to start.

You might want to find that relay and clean up the connector and check for water leakage into it.

That how I had one fail. It took a long time to get bad enough to find.

It’s very obscure on wiring schematics.

Now to say more about idle the electric heaters of the auxiliary air valve and the control pressure regulator. They are only trying to mimic and engine warming up from a cold start. Eventually the heat of the engine gets in there!

The coldness of these components can vary depending on various condition under the hood.

The engine will have some minor quirkinesses, of its on, but overall, it’s still not bad.

The K system is very reliable but not as precise as the later LH systems.

The LH’s have their on quirks just because they try to be so precise with everything including the A/C or Transmission loads.

You did not mention if you have a manual or automatic transmission? That can vary idle schemes to some extent.

I can only guess because, I have no experience with automatics tied to a K Jet system!

I know nothing about how it’s adjusting the idle going into drive.

The 1980’s A/C’s must have controlled “vacuum leaking valve” to bump the idle up for that.

The first LH’s came both ways up around to 1985, I think. On my 1986 they dumped that valve.

The ECU/IAC has rpm load control abilities for everything!

On My 1978, I adjust that auxiliary valve opening to a twist drill shank thickness setting, that gives me around 1200 plus (it truly depends on the coldness) rpm cold and the about 1000 when all warmed up.

A 2.1 Small Liter just spin up a little more than the B23 and B230s for that torque range.

It takes care of the A/C load for me.

This related to expenses like an AMM, IAC or a fuel pressure regulator.

The K does what they do just about the same in MPG.

You did not mention if you have a manual or automatic transmission.

Of course the “K” showed them how to make the engine run cleaner, over carburetors and it then evolved or morphed with the upgrade with electronics, to stop mimicking and sense things!

The K Jet has more character with it changes. It’s just like with us human folks, with their subtle quirks!

(:-)

Phil

|

|

-

|

|

|

If yours is like my 80 was it has a warm up air valve that opens more when cold and is heated electrically. No Idle motor. Mine did that too at times especially after getting off the freeway. I would check the connections to the valve. As I recall it is on top of the valve cover. I don't have that car any more so I cant look at it. Make sure the hoses are good and tight too.

|

|

-

|

|

|

U.S. California '81 242 B21F no idle screw. You might connect a vacuum gauge both when running normal and when you sense it's not. Install a T that you can leave in so nothing will be disturbed by connecting the gauge. This will give you some quantitative data and allow you to check other things.

|

|

-

|

|

Changing the idle screw setting is the wrong approach. It's unlikely that the screw is changing position.

US model? Does it have an oxygen sensor? Does it have the Auxiliary Air Valve or does it have the throttle switch? AAV is most likely.

Have you set the base idle mixture? You need to be certain that there are no vacuum leaks before doing this so if you are confident that this is the case I can give you the procedure. It would be a good thing to do if you have had the car for a long time and it has not been set.

--

'80 DL 2 door, '89 DL Wagon, '15 XC70 T6 AWD

|

|

-

|

|

|

Yes, based on my vague recollection of such problems with a B20F (similar to your B21F), the AAV is a good suspect. Does yours have the adjusting nut? When they start to get a bit weak in response, you may be able to try tweaking them by forcefully rotating the bi-metallic sleeve a bit to respond a bit more sensitively. As I recall, it seemed to help, but then I was probably trying all kinds of other things. I only recall replacing the AAV once with a new one, then mostly out of desperation, not knowing for sure if it was the entire source of the problem. Keeping the entire intake side clean and tight, making sure there are no injector seal leaks, is just as important. Do re-check your injector seals when the engine is stone cold by spritzing around the base. The seal will improve as the engine warms so it can be deceiving. Good luck.

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

|

|

|