|

|

|

Thanks all.

One of my exhaust manifold studs came loose. I realized this after the nut fell off and when I went to tighten it, the stud started spinning. I thought that the threads on the stud were just damaged and that a new stud would thread right in.

After purchasing a new stud though, I have realized that it is not threading into the manifold properly. I can get a few threads started and then the stud just spins without advancing any further. My guess is that some of the threads in the manifold itself got damaged in this process, too.

Looking for some advice at this point. I am not sure if there is adequate working room to tap new threads (or to chase chase the existing ones), but I am concerned that if I try to tap the same size M10 threads that I will remove a small amount of metal such that the stud will not fit tightly when I manage to get it installed.

Does anyone happen to know the thread pitch on these studs for reference? Thanks

|

|

-

|

|

|

Hello,

The threads are 10mm x 1.5.

If the threads are stripped in the manifold, the best way to proceed is to repair the threads with a Heli-Coil.

To install a Heli-coil, the stripped hole has to be drilled and tapped and since the hole is blind(not open at the end), a bottom tap should be used to finish the threads at the bottom of the hole before the Heli-Coil is installed. If you don't use a bottom tap, the Heli-Coil or the new stud can bind up before it is installed all the way.

You can either remove the front pipe and install the Heli-Coil with the manifold still bolted to the head or you can remove the manifold to install the Heli-Coil.

--

Eric

Hi Performance Automotive Service (formerly OVO or Old Volvos Only)

Torrance, CA 90502

hiperformanceautoservice.com or oldvolvosonly.com

|

|

-

|

|

|

Hi,

I agree a Heli-Coil is a good way to go and the finished end product will be stronger than the original threads because the of material the Heli-Coil is made of.

Sometimes a Heli-Coil is used in original manufacturing of new items.

Now, if my memory serves me correct a Heli-Coil requires its own tap to put thread in the material to accept the Heli-Coil. That can appear expensive for only one hole and if this is a recurring problem one might like to do all of the holes to get into cost averaging! (:-)

I will suggest an alternative procedure and that is to go up to the next millimeter size as the hole in there is probably already wallowed out to approximately the minor diameter of an Eleven millimeter thread.

He might need two taps, like you said, it a blind hole like you said.

Can he go all the way through or deeper as he is plugging it anyways?

A trick to remember with metric threads is the “tap size chart” is already written there within the size description of the thread.

You subtract the pitch of the thread from the major diameter and you get the minor diameter for the tap to use.

I like metrics for that simplicity over the unified threading system. I think unified means “stolen” from each other. (:)

Neither thread system is really better after that. The helix came from the Dutch pumping screw!

We have pushed our influence over the rest of the world but we are relenting.

Fractions are next except within some conversations, world wide.

Yep, I’ll take half of that since we’re sharing! (:-) who says, POINT FIVE or POINT Two Five?

Maybe someday, if we keep listening to machines? (:)

Next thing, will a larger Nut, Socket or wrench clear its sides? I don’t know?

In my days I heard this slogan, “If you cannot quite get there, you can try to beating it to fit and painting it to match! (:-) (:) or weld it, was popular too?

Cast iron doesn’t weld well! (:)

Phil

|

|

-

|

|

|

Thank you, Phil and Eric. Appreciate your help to no end

Forgive my ignorance, but when you say that this is a "blind hole" that needs a separate tap at the bottom of the threads, I picture threading into a block of metal that has no end, and as such, is not a "through hole."

But when I stand above the engine and look down at the manifold/downpipe connection, I can see the top of the stud because the hole in the manifold comes all the way through up to the light of day. Said differently, if I try to thread a new stud by hand, I can see the top of the stud spinning as I attempt to unsuccessfully thread it from below the manifold/downpipe connection.

Is there a discrepancy in what I am describing versus the setup you expected, or perhaps I am just misunderstanding the correct terminology. Thanks both

|

|

-

|

|

|

It appears I misspoke. I was pretty sure that the OHC NA exhaust manifolds didn't have a through hole for the exhaust flange stud holes, but I didn't grab 1 out our pile and check.

I did ask my brother, who also thought all of the holes were blind but I guess we were wrong.

In this case, if you're going to install a Heli-Coil, it's a good thing.

You won't need the special bottom tap for a Heli-Coil for that hole which is not included with the standard Heli-Coil kit and has to purchased separately.

--

Eric

Hi Performance Automotive Service (formerly OVO or Old Volvos Only)

Torrance, CA 90502

hiperformanceautoservice.com or oldvolvosonly.com

|

|

-

-

|

|

|

Hi Dave,

Depending on how long the manifold has been in service, and the condition of the other studs, it may be worth your while to pull the manifold. It may seem like more work, but you'll end up with new exhaust gaskets and copper nuts on the manifold to engine studs, 3 new manifold to header studs if you like, and an easier job of drilling and tapping a helicoil.

I often do this as a matter of course if the header bolts and nuts look like a dog's breakfast. It's an ungodly place to be working and I find it better to pull the manifold and header pipe out from the engine bay as a unit to where I can deal with it on equal terms. Just a thought.

regards, Peter

|

|

-

|

|

|

Thank you, Peter. This is good advice. I think you are probably right as frankly my whole exhaust system needs replaced and this is probably as good a time as any to fix it all properly.

Do you have any tips for breaking the manifold mounting nuts loose? Maybe warm the engine first and just take it slow with some penetrating oil? And likewise for removing the studs, I imagine you just have to jam two nuts on each stud and spin them out. Any big risks that the threads on the block will be shot afterwards? Maybe by the time I am done I would be a pro at installing helicoils anyways!

|

|

-

|

|

|

Hi Dave,

In general terms, there might be a tip in the words of Alessandro Mazzucotelli (1865-1938), an Italian blacksmith whose work I admire.

" Iron should be treated like a woman; she seems hard and terrible, but with a little warmth she turns soft like wax. And when it seems to rebel, do not mistreat it and hammer it furiously. No! You have to treat it gently and caress it."

He's talking about forging but the same principle applies. Resist brute force and you wont break anything. With patience and the right approach, you'll be able to have your way with it.

Rust expands when it forms between male and female threads, and exerts a tremendous pressure between them. It must be worn down with some movement before they can turn.

The expansive force of heating and the contractive force of cooling can provide this, but the heat from your engine is insufficient. If you don't have an oxy fuel torch, a Mapp gas cylinder on a Benzomatic torch might be enough. It might take multiple cycles with applications of oil in between. Resist turning the nuts or studs when hot because they are weakened and prone to galling.

You can also mechanically stimulate them by tapping on the nut faces with a small ball peen hammer, or a ball headed drift.

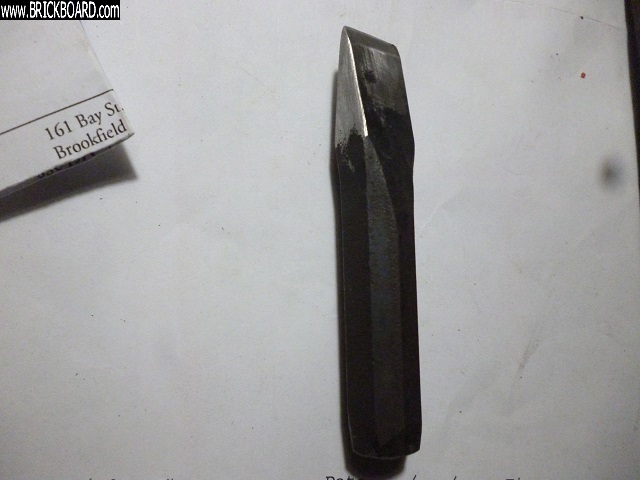

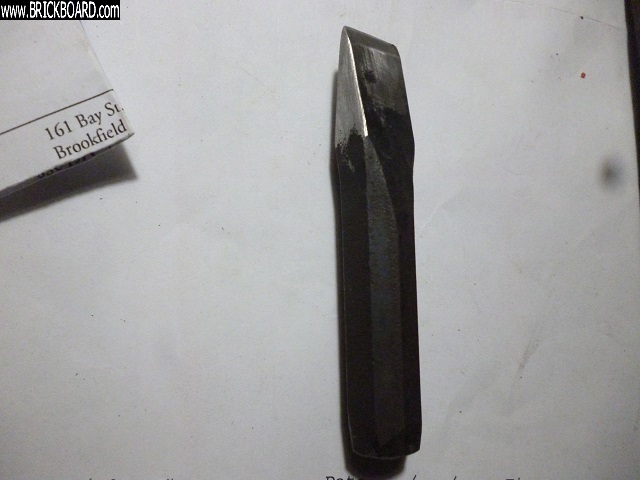

I've had considerable success with a stubby cold chisel that I made.

It's 3.5 inches long, short enough to swing a 2-3 lb hammer in the space available. I make multiple small cuts into the nut face which in theory expands it a bit. The shock may also be a factor because the studs more often than not come out of the engine with the nuts attached.

The chisel has a 30-35 degree as opposed to the normal 60 degree. Most cold chisels are supplied much softer and weaker than they are capable of being. They want them to deform instead of chipping or cracking if they're abused. This chisel was made harder and stronger to handle the small angle and retain it's cutting edge.

I've never had to go much farther than what you see. If the cuts are too deep it begins to be difficult to get a socket on. It may need to be hammered on. The nuts could be completely cut off without any damage to the stud.

As to the studs in the outlet of the manifold, you'll have to see what you can do. Sometimes there's no alternative but to heat up the studs and the area around it to red and let it cool slowly. In the worst cases, that might have to be done more than once.

regards, Peter

|

|

-

|

|

Excellent write-up!!!!!

As I've been doing since 1984. Penetrant, tap-tap-tap, regular engine heat, cold, penetrant, tap-tap-tap ... out come the exhaust studs from the head. Sometimes weeks and months.

I may have used a touch of propane torch to heat a nut a few times. With penetrant.

Big, big thumbs up! Way up!

Siskel and Ebert.

--

Beh.

|

|

-

|

|

|

Hi there fellow wrench pullers!

You guys are talking about a “nut splitter” method and I have only seen one of those apparatuses in my lifetime and I don’t own one.

I looked them up on the internet and from the variations in prices, quality and designs, I can see why they are not just laying around on tool stores shelves or on garage sale tables!

Also from the looks of them, they are pretty hard to get into tight places or close enough down above or around what ever the nut is holding!

Yep it’s a good right up and with pictures too!

This is what I call a straight on approach to a problem told nicely!

I could see making a finger held holder for a hardened tool steel blank with the maximum of two wedge points sticking outward from its face.

The holder could have short rod handle on that short holder to make room for the hammer.

Almost like a short version of a hammer driven impact driver without the twisting action!

It would have to align some, to some extent, on each side of the screws male portion since it expands the nut.

Probably would have to be a whole set of them made to cover the common individual sizes.

Clearance to be close but not too close, for them to work well enough to sell and not clutter ones tool box for their occasional use!

The occasional use makes some of those prices totally ridiculous!

A whole cutting torch outfit would make more sense!

Thanks for sharing with the Brickboard forum!

Phil

|

|

-

|

|

|

Using a larger stud maybe a problem when it comes to installing a nut as even Volvo uses a reduced head nut for this application.

--

Eric

Hi Performance Automotive Service (formerly OVO or Old Volvos Only)

Torrance, CA 90502

hiperformanceautoservice.com or oldvolvosonly.com

|

|

|

|

|