|

|

|

Car is a 91 240 Sedan Auto, Air, Bosch 2.4, B230F

I had have initially attacked this issue from the intake side and cleaned and re-adjusted the throttle body following the steps in the Bentley manual. Also changed the fuel pressure regulator. Started the car up and it ran great until it warmed up. Then it still ran great as long as it was rolling. Going down the hiway it feels better than ever. However sometimes when it comes to a stop its idling fine and then when I give it a bit a gas to take off she stalls. She will start right up and may not do it again for a few stops, but it will do it again cause it did when I got home today. Now if I keep my foot on the gas pedal and speed the idle up a little bit it usually does not stall. My thoughts/questions are as follows.

Idle speed as measured with a tach is about 800-850 rpm, which is a bit more than spec. The throttle switch clicks as it should. Idle speed is constant even if I turn the AC on or off.

Fuel pressure regulator and filter were replace a few months ago

Coil, wires and plugs were replaced less than 5k miles ago

Crank position sensor and wiring was replaced as I was getting a code for intermittent signal, the harness was inspected and no obvious corrosion or faults were seen. Replacing the sensor took care of the code.

At this point I am thinking maybe I have a fuel supply issue, Maybe too rich or lean at idle? Maybe a bad injector?

Cold start injector was replaced by the shop a year ago, but I doubt that has anything to do with this.

I did quite a bit of searching on the net and found a few discussions of similar issues but no solutions.

Any insight would be greatly appreciated.

Thanks,

Don

--

1991 240 Sedan auto

|

|

-

|

|

|

Don, you don't seem to be having much luck dealing with the ongoing stalling/idling problems with this car based on the varied advice you've been getting and everything you've done. It's like you or we are missing something basic here, so maybe we should try to back up a bit.

Right off the top I'm noting an inconsistency. You say you have an LH 2.4 B230F, which is indeed the norm for a '91 240 with automatic, but at the same time you mention the cold start injector having been previously replaced. LH 2.4 does not have a cold start injector, but LH 3.1 does (which is the norm for manual trans 240s of that vintage). Please verify which injection system you have. The AMM should end in -016 for LH 2.4 and in -001 for LH 3.1. The TPS used with LH 3.1 is variable resistance and is much more prone to fouling and failure resulting in the kind of stalling issues you describe. Also, please verify which TPS you have. The Volvo adjustment procedures are quite different for the Bosch and VDO TPS switches used with LH 2.4 and may well be different again with the LH 3.1 TPS.

Another basic thought. As Phil noted, the idle system is very dependent on a few sensors and being able to properly control the IAC valve. I think it would be wise at this stage to go back and use the OBD system to make sure the ECU is seeing signals properly and able to exercise basic control. At this stage you might as well try going through all the steps of DTM (Diagnostic Test Mode control functions) 1 to DTM 5 as described in the 700/900 FAQ here. Of particular interest at this moment for your problem:

o In DTM 2, make sure you can get the 3-3-2 code to indicate the ECU is properly seeing the TPS click. It should not be set on the hairy edge, the throttle needs to open very slightly before getting the click, which the Bentley adjustment procedure should correctly describe. I note a few of the procedures in the FAQ are improperly or incompletely described. To get the 3-3-3 WOT code you start by holding the throttle wide open, then press the button twice (1-2 secs each) to get the LED flashing then slowly release the throttle to get the 3-3-3 code. To get the 3-3-1 code for the RPM sensor you start the engine.

o In DTM 3, make sure the IAC valve does a solid tic-toc as it hits the ends of full travel. You can also feel it with your hand. Letting it cycle through DTM 3 a number of times (like 10 or more) can sometimes temporarily help a sticky IAC valve, so if it behaves better right after doing these tests then that's a good indicator. Put your hand on each of the ticking injectors to sense more or less even operation, although I don't expect you'll have a problem. If you have LH 3.1, the cold start injector should tick as the next step.

Other questions I have in my mind are the nature of the stall. Does it always stall or just occasionally? Is it the same when warm and cold? Do you have to feather the throttle open to keep it from stalling or does it only stall when you hit the gas? Is the idle otherwise fairly smooth and as well the engine fairly smooth when it's at speed? Have you pulled the spark plugs and read them? Also when was the last time the distributor cap and rotor were replaced, also the fuel filter?

And back to the throttle body. Is there any chance someone has ever tinkered with the throttle plate location on the shaft? The two brass screws typically have a drop of thread locker that can help indicate tampering. When fully closed the plate should be more or less evenly centred (centered) when you hold it up and look through to a light source. With the TPS removed, the shaft should not stick out more than 21.5-22.5 mm (a bit less than an inch). If it protrudes too far it can cause binding in the TPS and premature switch failure.

Finally, when idling, what happens when you pinch closed one of the the air bypass hoses to the IAC? Use blunt jawed hose pliers meant for the job or well padded regular pliers to avoid splitting the rubber. The engine should stall out (or the revs drop at least below 470 rpm) otherwise there's a problem either with adjustment or the IAC.

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

-

|

|

|

I'll answer what I can and the rest when I have time.

About the cold start injector, I did not replace it the shop that I bought the car from did. which is a Volvo specialty shop, the receipt said cold start injector, Fig.2 on page 241-5 in the Bentley manual refers to it is as the "Cold start valve". However I have not cross referenced the part number. I'm not being argumentative just stating the facts that I have. In any case it did not really make a lick of difference when they did it, it was a bad CPS giving me issues that time and they missed it.

About the stalling it is occasional but more frequently lately, thats why I have been messing with it. Other than the stall, the car runs, starts, and drives as it should probably as well as it has ever ran. I can sometimes feather it and it will not stall, I can also slightly 'power brake" it and it does not stall.The longer it idles the more likely it is to stall.

Acceleration once slightly off of idle is as it should be. This is my 4th RWD Volvo I know how they should feel, 0-60 in 2.0....mins HAHA. Joking aside this one runs better than my others except the Hot rod 72 144, which my brother murdered.

Fuel filter 6 months ago more or less, Cap, rotor and plugs maybe 3 months ago, mostly because I checked them and they seemed worn. Coil at the same time cause it was original and the wiring to it was crappy. That has been replaced with proper connections soldered and sealed.

I highly doubt it has a 3.1 system in it as I have gobs of receipts and nothing indicates that change, the TPS numbers on the original switch are exactly the same as the replacement which is for a 2.4. How would one determine with 100% certainty which control system was fitted to the car.

There is no EGR.

Thanks for the tips with the DTM, I'll get to that when I am back at my garage with the car. In a few weeks.

--

1991 240 Sedan auto

|

|

-

|

|

|

Good reply, Don. I look forward to your additional responses as you proceed with further diagnosis.

The more I'm reading of your problem and progress, the more I'm smelling an electrical gremlin present, like an intermittent electrical problem somewhere, possibly temp, ground or wiring connector movement related, either with the TPS switch, IAC valve or some other component directly related to the ECU or ignition control module sensing or controlling engine speed at idle and during the transition away from idle. That's strictly a hunch as I have not encountered or heard of exactly those issues, but I would at least keep such possibilities in mind as you attempt to further diagnose your problem hoping for something to jump out and definitively point to a problem. Having said all that, as much as it smells that it's on the fuel side, do keep an open mind to having problems on the ignition side.

As for LH 2.4 vs LH 3.1 in your '91 240, the VIN and/or product plates can be used to verify what it was originally supposed to have, but to see what it actually has it's usually simplest to check a part number like the TPS or AMM as I suggested. As I noted, only 240s with manual transmissions in those early 1990 years reportedly had LH 3.1.

As for a cold start injector, once again I stand to be corrected by real world obervations and not just the few cars and references I have experience with. I've been around a number of LH 2.4 systems in 240s, 700s and 900s and none have had a cold start injector nor do any of the Volvo green electrical manuals for those years I have show a cold start injector for the LH 2.4 ECU (but do for Regina). Yet, once again I have to defer to the observations of you and others that indeed, some LH 2.4 did have a cold start injector (p/n 3517130, I believe). Looking at Bill Garland's ECU database, it is clear that some LH 2.4 systems still had cold start injectors well into the early 1990s and that 240s may have been the last to move away from them. I find it odd that cold start injectors were ever needed with a pulsed injection system. The ECU can easily do a fairly decent job of duplicating the cold start injector function on demand by simply double pulsing the regular injectors during cold cranking. I'm not sure why an unneeded legacy device from continuous injection days would have been kept by some of the Bosch engineering programmers.

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

-

|

|

Dave, I think the 5th injector was dropped in '92 when the fuel rail got the not-so-handy Schrader valve test port. Our 91's all have the cold start injectors.

Just skimming what has gone before in this thread tells me the TPS is still a suspect. Clicking isn't the definitive test of this device as it may have been years ago when these switches were fairly new and clean. Now, a reliable TPS can only be determined by an electrical measurement, because the switches have become old, weak, and contact surfaces contaminated by blowby oil. The result is the switch closes (for idle) 9 out of 10 times, then 4 out of 5 times, then 2 out of 3 times long before it gives up entirely.

That behavior matches the complaint.

--

Art Benstein near Baltimore

You can easily judge the character of a man by how he treats those who can do nothing for him. ~Malcolm S. Forbes

|

|

-

|

|

|

Very much agree, Art, on properly testing the TPS with a meter to witness a nice crisp, solid switch contact with little or no electrical resistance. Also smooth electrical resistance throughout the range for the LH 3.1 switches. Prior to hauling out the meter whenever I'm suspicious, I always start with a simple two minute test using OBD DTM 2 to make sure the ECU can even see it. No tools, work clothes or dirty hands required. Once, when I hadn't solidly seated the TPS connector underneath, that allowed me to immediately identify the problem that might have taken me an hour to finally spot.

As you suggest, high mileage commuter cars such as Don's are probably more likely to suffer from blow by, PCV issues, dirty throttle body throats and worn throttle body shaft bushings to hasten fouling inside the switch. Additionally, worn or misadjusted switches on the hairy edge of adjustment may be more likely to suffer from arcing and contact pitting. Also my note elsewhere in this thread on proper throttle body adjustments and the throttle shaft possibly extending too far into the TPS, increasing wear and causing binding. That can all lead to early switch failure. Replacing a bad switch with a used one of unknown internal condition can create a false sense of security and cause people to stop thinking about the TPS as the source of a problem.

I always keep my throttle bodies clean, properly adjusted, and the connectors packed with greased. I have never had to replace a TPS on any of my cars, some well beyond the 250K mile mark. Having now said that, I know my beasts are likely sitting outside already plotting a TPS failure as their next gotcha.

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

-

|

|

|

Art is right. When I pulled the TPS it was full of blowby and very sticky the click was barely audible. so I replaced it with a brand new Bosch unit. I will test it anyway as the issue could the connector, or the wiring. I did set it on the hairy edge though so I will go back trough that process.

--

1991 240 Sedan auto

|

|

-

|

|

" I did set it on the hairy edge though so I will go back trough that process."

That could be a big part of the issue. Such emphasis is put on having the switch click as soon as the throttle plate moves that diligent attention to that advice winds up going too far. For one thing, the audible click isn't enough to assure you the contacts are making. You need just a bit of free play on the closed side of the click. The snap action switch geometry needs it. Also you ought to be more concerned the idle circuitry is engaged than disengaged immediately as your foot touches the pedal.

Of course the trade-off is you don't want the car to leap forward when inching a long in traffic, so setting the edge with no hair but not sloppy will let your foot open the throttle instead of the idle bypass. When the switch is open, the idle valve receives a signal to keep it partially open a fixed amount, not closed, so the airflow should increase mainly with the throttle opening. The AMM should read that and send some fuel.

Bottom line, no hairy edge.

--

Art Benstein near Baltimore

Mother Superior called all the nuns together and said to them, 'I must tell you all something. We have a case of gonorrhea in the convent.' 'Thank God,' said an elderly nun at the back. 'I'm so tired of chardonay.

|

|

-

|

|

|

Hi Art and gang!

I agree with you Art. Like you said, he didn’t have to go to the trouble that said he had done,

" I did set it on the hairy edge though so I will go back trough that process."

I think I was using a phrase like “A wiggle of the plate.”

If he sees the plate open, then there should be the click following.

The switch will go through a “change of state” on the volt/ohm meter, if one is used!

Its like listening with only one eye open? (.-)

Yes, even a meter with a piezoelectric buzzer helps!

I agree that knowing that it’s working repeatedly back and forth “visually” can be the best method, especially, if the person is like me who doesn’t know to what frequencies of sounds are missing!

It doesn’t help either to forget to put in the hearing aids either! I also or run the last bit of juice out of them, on one side or the other! They will ding for three or four hours before truly dying and one long before the other one!

This is for all readers!

I agree the Bentley does have a mixture or blend of setting procedures.

Luckily we have grown through the differences and are aware of the changes done to evolve to the LH’s.

The setting of the rod linkage to the pulley tab space and slack in the throttle cable behind it, can bring forth a feeling of “fussiness.”

It’s best to learn where there’s a certain amount sloppiness to be achieved!

The pulley tab needs space to fall forward so the pulley doesn’t stop the throttle from closing.

The cable slack is to allow that, plus, not pull the pulley back with the engine shakes or rocks sideways under power, or the lack of, it during deceleration!

The slack adjustment is a human preference thing when it gets down to it and lots of things are that way in reality!

Once you get the mechanical looks matching the needs you will find the the throttle linkage rod cannot be adjusted very much but has to provide the gap for the pulley tab.

On the early K jets there was a feeler gage call out specification there!

That was when a “Continuing Education Student” was standing there with his note book and just had to write down something.

That person, he or she, had to appear “ appreciative” to the mechanic, that was sorting out the designs quirks because it had to work in the real world!

In my days, we all had to pay forward some “homage” to those who already had things working for them! Today, I call it paying your “DUES!”

I wouldn’t have the skills I have had I not buttered up an old guy or two along the way!

I figured out the my elders were a book that you could open as long as you were sincere about turning their pages with interest in their content.

Some would call them shortcuts but it was their wisdoms cataloged.

There is one thing that I also do, and that’s to always leave a little bit to be figured out, for the person turning my pages!

I found this out, unintentionally, as you cannot answer everything that they haven’t figured out to ask you!

This stems from not knowing what they know and you assume abilities that have not grown yet.

(Magic?) happens, when they exclaim what they discovered they can do and you just smile back that the light came on inside!

I admit, I helped the “grasshoppers” more willingly!

Teachers know it places a desire to learn more in their lives.

Skills obtained can never be taken away!

One has to remember that books or manuals are only a guide to circumvent the longer road to learning something a harder way. Our ancestors have done for us!

With these two way forums of recent, good or bad, there’s no excuse not to learn as much as you want, but applying it will be always an interesting challenge!

Phil

|

|

-

|

|

Hi Phil,

I enjoyed reading it all.

--

Art Benstein near Baltimore

Sometimes, we just need to remember what the rules of life really are:

A. You only need two tools: WD-40 and Duct Tape.

B. If it doesn't move and should, use the WD-40.

C. If it shouldn't move and does, use the duct tape.

|

|

-

|

|

|

I was finally able to get back to messing with 240. I followed the revised guidance in the TSB that you guys have provided. I had the idle stop screw and throttle switch improperly adjusted. The switch was set so close to the edge that it clicked when I was loosening the 3 bolts. However, I am still little confused by this.

For a Bosch switch, hold the throttle plate closed, turn the switch counter-clockwise until it clicks, OK got that part; then continue to end of travel and lock in place, What I think this is saying is turn the switch until the throttle plate starts to open after the click, because if the throttle switch is rotated to the extreme of its range the throttle plate will open.

Well, after setting them correctly (I think) the car runs better, but I would not say perfect. The is still a small stumble coming off idle after the car has warmed up. When the car is in closed loop (not up to operating temp yet) it runs idles and takes off perfectly, once it goes into open loop there is still a slight hesitation when coming off idle. I haven't been able to take it for a long drive yet, so when I do soon that should let me know if there is a real or imagined issue.

--

1991 240 Sedan auto

|

|

-

|

|

|

Good, that all makes sense with your symptoms.

As for the the Bosch TPS adjustment spec, keep holding the plate firmly closed and rotate the switch to end of travel, don’t force it, you don’t want to start opening the plate, then secure in place.

Wouldn’t hurt to put a marker, like a drop of paint, liquid white-out or thread locker, on the idle stop screw and TPS as a tampering indicator so the next poor guy will know it’s still adjusted to factory spec. These are pretty much set and forget adjustments. There’s a great tendency for neophytes, especially those of us from the carb days, to play with these adjustments when there are idle problems when the problem is something else, like a dirty throttle plate or throat or misbehaving IAC valve. I was once guilty of that myself.

As for your continuing slight hesitation/stumbling issue coming away from idle most noticeable with a fully warmed engine not a cold engine, it’s usually the other way around. You have to ask yourself what’s different between a cold and hot engine. One is that LH 2.4 doesn’t listen to the O2 sensor until the engine is hot, also that the ECT is passing a different signal, also that any deposits on the plugs are now glowing red, but I don’t associate any of that with your problem. One thing I can think of is the IAC valve spending most of its time in a slightly different orientation as combustion efficiency has improved. It may be sticky, fouled or with contacts now operating in a different area on the motor armature where a bad wear groove may be present. I’d try that easy OBD DTM test I mentioned to exercise the heck out of the IAC and see if the world temporarily improves or changes.

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

-

|

|

A few remarks on the LH2.4 comments

"One is that LH 2.4 doesn’t listen to the O2 sensor until the engine is hot"

I have read this before on this forum, but in fact the O2 sensor starts operating quickly, long before the engine has reached operating temperature as it's electrically heated. Volvo says "Because of this system, the Lambda-sond quickly reaches operating temperature, even at low exhaust gas temperatures."

In my experience with a failing FPR, it takes just half a minute for the O2 sensor to start working from a cold start.

"the IAC valve spending most of its time in a slightly different orientation as combustion efficiency has improved. It may be sticky, fouled or with contacts now operating in a different area on the motor armature where a bad wear groove may be present."

The 1991 version will probably no longer have the brushed but a brushless version of the IAC in which case there's no possibility for a wear groove. Dirt, however, will still play a role.

|

|

-

|

|

|

Right, I was rather thinking out loud with some common LH warmup issues that might or might not apply to your symptoms and was indeed thinking about the slightly more trouble prone older style spring loaded IAC valve design used with LH 2.2 on earlier 240s and 700s and as well the early unheated Lambda Sond O2 sensors which took much longer to reach operating temp. A sticky IAC should still be on your hit list, as you said.

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

-

|

|

|

Update,

I gave the car to my wife to drive last week, so I must have been confident. Anyway it stalled on her! I was puzzled but I thought I had not changed spark plugs in a year or so. So I changed them today drove all over town went to get the car inspected as it was overdue and got the hard ass inspector. The shop is owned by 2 brothers one is easier to deal with than the other. Anyway I passed no problems. I drove all over town well city and highway. No issues. Reading through my previous posts I stated Plugs were changed 3 months ago, I was mistaken, it was more like 18 months ago.

The gaps on the plugs I removed varied from about .030 to .040. Based on looks they were pretty pale maybe a bit lean. New plugs were gapped at .028

So replacing the plugs made a good bit of difference and the car runs as it should now.

--

1991 240 Sedan auto

|

|

-

|

|

|

Hi,

Thanks for the update.

Yes, I can believe that spark plug gaps can effect performance.

I have found out just the way you did by realizing that those plugs are in there longer than one remembers.

These engines are so self tuning that they will hide this little detail of a slight consistent wiggling of the block on the mounts! Is it a lean burn or delayed firing as it gets so adjusted out in milliseconds.

Thanks for reminding us of such an easily forgotten maintenance item.

Phil

|

|

-

|

|

|

Good! I’m sure you're glad to find something specific that would explain your stalling problem. The TPS was indeed the most likely candidate to explain your symptoms, so hopefully that's all there is to it, but you had mentioned prior replacement so that did open up thoughts for us trying to guess other possible causes, plus it always takes a little back and forth to make sure people’s observations are the entire story. It soon became apparent you were no neophyte, so all the more challenging. For proper adjustment of the TPS depending on the make of the switch, you will hopefully have noticed my prior reply to Machine Man Phil elsewhere in this thread. Good luck!

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

-

|

|

|

Art,

I had the same thought, regarding the switch when I removed it did not move well when the shaft was turned, I sprayed it the best I could with contact cleaner, and was still not happy with it, so I replaced the switch with a new Bosch unit with an identical part number and arrangement. Admittedly I did not put a meter on the new one, as I ASSUMED it was ok.

Dave's hunch may indeed be correct that I have an electrical issue. I posted a few months ago when this saga started in May that I had to replace the CPS a couple of times, and that seemed odd to me. Its on it 4th in 2 1/2 years. The shop that had it before I got it put 4 MAFs in the car and never figured out that the cold air side of the air box was blocked off by the thermostatic valve being stuck. I found that a touch annoying and went back to the shop to explain to them that these or any cars will not like running on heated air, it will lean them out. Also the piping from the Airbox to the headlight was missing. Dryer ducting worked well for that. The wax valve is long gone now.

Anyway I bring that up because they may have adjusted the throttle body settings to compensate for this. The lead me to focus on the TB and TPS settings as a fix. Which may still be incorrect based on the information provided by you guys. I will go back through that procedure first.

One other observation I failed to mention is that after I cleaned the TB and set the TPS I hooked my 30 old Dwell/tach meter to check idle speed, when I did the idle changed and it surged for a second or two. I think that is odd. Maybe the computer sensed the change in impedance? It was almost like diesel hunting due to governor fouling up. The coil is brand new and is a Bosch unit with the correct part number.

Early in my career I was an electrical automotive tech, so I know my way around a meter, kind of, that was a long time ago, and lots of folks are better than me. I then transitioned to large Detroit diesels 16V71s and moved on from there. I bring that up because I was taught in diesel school to check the easiest most obvious thing first. Electrical grounds on an spark engine being one of those things. I kind of broke that rule here I am afraid.

My daughter had the car for a bit as a loaner while I was sorting out her Honda, and it went through a bit of trauma, where the exhaust flange broke at the manifold and the exhaust got dragged for a while, she was able to secure it with a coat hanger but had to drive home 60 miles in a tropical storm with an open header. The engine seems to have survived that. I went and trailered the car home then. It was stalling occasionally before that event though.

One other observation I had before I put the car away is that I may have a broken engine mount, I was able to replicate the issue in my driveway with the hood up by working the throttle pulley, and the when the engine died it jumped around quite a bit. If a mount is broken that could indeed stress out some wires and cause intermittent problems. I did inspect the CPS wiring it has a good amount of slack in it and the connector fits into its holder on the fire wall, at least it was there last time I checked. The wiring to the O2 sensor seems ok as well, it actually has too much slack in it for my tastes as it is close to the driveshaft.

I really do like this car, I sold my 91 ZR-1 and kept this one, that should tell you something. I do want to get this fixed.

For now I am off to go hide in the woods for a couple of weeks.

Thanks again for all the help Guys. I will let you know what I find out. Subscribed now, Thanks.

--

1991 240 Sedan auto

|

|

-

|

|

Oh, and about that old dwell/tach.

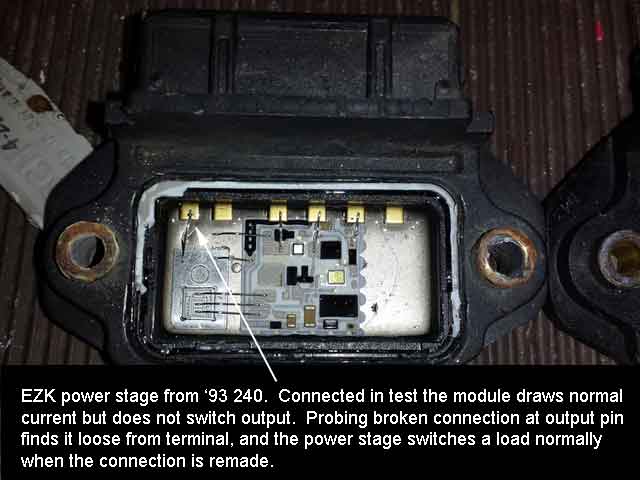

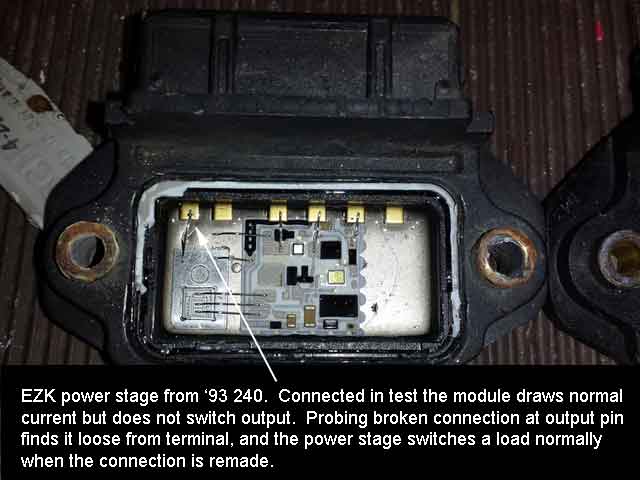

The EZK computer is well-isolated from the coil by the amplifier module, aka power stage. Some on this forum believe this is just a dumb solid state relay, but Bosch has built some sophisticated ignition management in where the topic is charging and discharging the ignition coil. I'm sure you're correct, that the load provided by that dwell/tach was reflected and sensed by the power stage. My old meter is not a sensitive instrument at all, incorporating a large inductor to derive the RPMs.

--

Art Benstein near Baltimore

"If you've got a heart at all, someday it will kill you." Rita Dove

|

|

-

|

|

|

I don't have a scope anymore or access to one, But I had a 87 740 with an intermittent issue and the scope helped find it. The wiring diagram for a 91 in the Bentley manual appear to have an error where the I got transposed into an L. It shows the CPS in L1 but it is clearly in I1. and the terminal numbers are pretty much unreadable, the colors are readable though. I think I have some other diagrams that I downloaded somewhere on this machine. To test the CPS I think one would want to measure resistance to see a varying resistance, at least that how I dealt with some ABS sensors previously.

--

1991 240 Sedan auto

|

|

-

-

|

|

"...use of a scope at ECU connector pin 3 ..."

Correction: idle side of TPS goes to ECU pin 2, not 3.

--

Art Benstein near Baltimore

Never interrupt your opponent while he is making a mistake (Napoleon Bonaparte)

|

|

-

|

|

|

Whats the condition of the 25 amp fuse and holder? Hows the fuel pump relay and related fuses? Coil connectors?

|

|

-

|

|

|

Hi,

What you have is a classic transitional problem!

I don't mean being a teenager or a having a mid-life crisis! (:-)

Being the idle is a little to fast, you might want to check a couple things back on the throttle body.

It's very possible that the throttle plate is now open too far. Too high of an RPM as it's getting air!

If the body was coated with black gunk then less air was getting through before the clean up.

More air causes a leaner condition even when cold but after a warmed up things lean out more and more RPM can be another indicator.

The opening on the plate has to be shut down completely, so that, ALL the idling air has to go through the IAC. (Idle Air Control valve)

This valve has a limited range of control and the throttle opening has to be set below the top end of its range.

Check for stop screw adjustment to be too fear up!

This screw is provided only to prevent the throttle from possibly being jammed in the bore by a rapid closure from throttle return spring on the cable pulley above.

It may have been tinkered with before to cheat around a too low of idle speed.

Especially if the car is new too you! It's a classic symptom.

If you follow the Bentley manual during your service, it will tell you to adjust it open slighly, don't do that! You only want to take spring pressure strain off the plate.

After doing that, the throttle switch has to be reset to click just as the plate is seen to wiggle open!

This gives the computer a "heads up" that things are about to change.

While you are doing all of this realignment, check the accordion hose for any possible splits or cracks in the volutes. I like to flex it some with a bright light up on the inside.

Make sure the hose ends are securely air tighten behind the AMM when done.

The Air Mass Meter is between throttle and the air cleaner. It's a precise gadget to measure the total air amount coming into the engine.

It cannot and will not adjust for any kind of excess air changes from vacuum leaks.

The ECU only works from what it's told from four sensors to set idle and run power mixtures.

As far as fuel pressures go, the ECU knows nothing about that.

It can work well up to a point with some variances.

But at this point, we will go with the gas pedal that is doing you in!

When things are right you should never have to touch down on the gas pedal. Turn the key and it should start, race up a little and idle right back down!

There's a fine balance around the IAC capabilities. It right there on an edge of a stall when the coolant temperature sensor says the engine is warmed up and to run a bit leaner as it cannot throttle back enough.

Hope this helps give you a working picture and where you are with these symptoms.

Phil

|

|

-

|

|

|

did you chk fuel pressure!!??

|

|

-

|

|

|

Thanks Guys,

I had the Throttle body out of the car and throughly cleaned it. It does appear that it is completely closed when the gas peddle is not operated. I did however have to adjust the idle screw to get it to do that. I used the 2 feeler gauge method to do that, as stated in the manual. Although regular sized feel gauges don't really fit well, a wire plug gapping tool works a little better. I will go back through that process. Regarding the inlet piping, accordion hose and related tubing, there are no cracks or breaks, I removed the accordion and used a bright flashlight while I flexed the hose, no cracks. All vacuum connections and lines are clear and any suspect hoses have been changed. The IAC valve looks relatively new.

I have had this car for about 2 -3 years. It was in commuter service 70 miles round trip every day.

When I got it, It had a bunch of differed maintenance issues and a very extensive service records. Which indicated 4 MAFS replaced by the shop in a couple of years under previous ownership. That was due to the cold air side of the airbox being shut-off due to a faulty thermostatically controlled valve in the air box, I bring that up cause I suspect they were chasing the same ghost. because it happed occasionally since I bought it but had recently gotten to the point where I took it out of commuter service because of that.

I have not checked the fuel pressure with a gauge but will do so it appears that hoses have to be cut and fittings inserted to check the fuel pressure are there any tips I am missing there.

On a sidenote, I have a project Jeep that was hiccuping at idle I finally had the injectors flow tested and cleaned and it runs better than ever. Not sure how that would work out for the Volvo. IMHO injectors are like spark plugs often overlooked and make a big difference.

I have to go on a trip and will deal with this when I get back.

So in summary:

Double check throttle body settings, ensure proper fuel pressure and see what happens.

--

1991 240 Sedan auto

|

|

-

|

|

|

Hi,

Yes!

Toss that wax thermostat from the air cleaner into the trash!

I put in a 5/8” square block of anything solid.

Wood, plastic, or one haft of a set of dice!

That way you stop gambling against an AMM going bad! (:)

Four AMMs must have created some sad times for that previous owner, especially at those dealerships!

Those poor guys or rich guys now, depending on a perspective, had their hands tied by emissions licensing laws!

Manufacturers make a boo boo and so the merry-go-round turns around and around running on the consumers wallet.

I learned a long time ago, that the ride is not always Merry with its up and downs!

On the stop screw setting, do not use a feeler gage to set the plate open.

Let the plate close completely with the stop screw backed all the way off!

Then bring the screw back up to the lever until it touches.

I then give it about the maximum of one quarter of a turn more or about the width of that screws slot and then lock down the nut.

Forget having it holding open that plate at all.

Any space under or around the plate is crucial and very quickly lets air in.

Remember there’s 20-21 inches of vacuum on the other side and when the plate wiggles, a bunch of turbulence is gonna whistle by! There are other vacuum ports in that area that go to work or are already working too!

You want them only getting what is needed, when needed!

The LH has a computer controlled idle.

Starting with the LH 2.4 the IAC got revised to a spring loaded return for better control and safety reason. The ones on the 1989 and letter have only a two pin connector.

The LH 2.2’s have three pins and is electrically driven back and forth.

If it looks newer, then yes, someone was chasing the ghost from time to time.

The earlier Bosch mechanical injection systems use heated up and spring loaded air bypass valves. The fuel pressure regulator that was heated up to also mimic the warming up engine.

Idle mixture and time varied accordingly to the ambient temperatures.

It works rather decently and reliably but standards on idle time emissions kept pushing for changes.

Fuel pressures and and air vanes settled the idle down to the stop screw setting during normal operation.

The person writing up the Bentley manual didn’t know to leave that out of pages following the advancement to the LH!

That procedure was used on the old K Jet systems and back when they also used a lever operated micro switch that was mounted out in the open air too!

We have that switch enclosed now.

A lot better and a more sanitary design from the contacts point of view! And yes, mine too!

The closer you can set that switch, to the actual wiggle of the plate movements at closure, the more accurate the transition to the off idle, over to power mode will be!

Right then, the computer will work setting up all the mixtures.

What happens is the gunk of Crankcase vapors restricts the opening over time and then some one thinks it’s not getting enough air, of which, is correct!

Trouble is they find that stop screw and play with it instead of doing what you have done!

You cleaned it and now, it idles faster than the IAC can shut it down!

I hope you find the problem and get yourself a “brass ring” for your efforts!

(:-)

Phil

|

|

-

|

|

|

Phil, yes, that's the problem for many of us shadetree types using Bentley, Hayne's and other manuals. These manuals were mostly written in the heyday of the early 240s with K-Jet and LH 2.2. In most cases LH 2.4 is briefly mentioned more as an addendum where there's minimal mention of specific differences. There's precious little mention of LH 3.1 which didn't appear until 1990-1991.

As to your notes on throttle body adjustment, I'll paste here a slightly edited copy of some old notes of mine that includes the actual Volvo procedures which in some cases are different from what you find in the FAQ and indeed those used by many here:

To adjust the closed throttle plate rest position, the 1/4 turn method is the correct Volvo adjustment procedure. With the lock nut loose and the TPS switch loose (not everyone remembers to do that), while holding the plate closed, advance the stop screw until it's touching the stop and to the point where the plate is just about to start opening. Advance the screw 1/4 turn more and secure in position with the lock nut. If you're a purist, Volvo calls for adding a drop of paint or thread locker to serve as a tampering indicator. This is all best done on the bench when cleaning, holding the plate closed from behind with your fingers on the lower edge of the plate to best sense plate movement.

You then adjust the Throttle Position Sensor switch with the throttle plate closed, rotating it clockwise until it clicks as it opens. Most of us just set the TPS switch so that it clicks just as the throttle plate begins to open, but of course it shouldn't be set on the hairy edge of clicking, there should be some freeplay. Volvo TSB 25-202 on LH 2.4 throttle body adjustment is much more specific and calls for different procedures depending on the TPS used. For the Bosch switch, keeping the plate held closed, you open it until you get the click, then continue turning it open until you reach end of travel then secure the screws. For the VDO switch, you insert a 0.25 mm feeler at the stop screw, rotate it open until you just get the click, then secure the screws. I'm unsure of the exact LH 3.1 TPS adjustment spec, but I imagine the same specs would be close enough.

With the throttle body installed, you re-connect and adjust the linkage rod between the throttle body and the throttle cable spindle. Again, most of us just adjust for a little bit of freeplay before getting the click. The Volvo TSB of course calls for feeler gauges to be used and it's different for the various engines. You insert the feeler gauge at the cable spindle stop tab (not at the throttle shaft stop screw) and tighten the linkage rod turnbuckle until you get the click. For all 240 B230F you're supposed to use a 2.0 mm feeler, for 700/900 B230F and all B230FT it's a 2.5 mm feeler, for all B234F manual trans and early production B234F automatics it's 3.3 mm, for later production B234F (w/auto TB tensioner and auto trans) it's 1.6 mm. Why there should be different spindle freeplay specs, I have no idea.

For adjusting the throttle cable, most of us will simply want to adjust the slack out of the throttle cable, leaving a minimal amount of freeplay to achieve an immediate throttle response at the pedal. I've heard of others wanting to adjust the throttle cable to achieve full WOT when the pedal is at the floor, which would only be correct if our cables were so short as to be taught when at WOT, but that is generally not the case and could inadvertently cause TPS malfunctioning if adjusted that way. Volvo of course has a factory adjustment spec, measuring freeplay at the pedal.

And finally, for automatics you get to adjust the kickdown cable. The Volvo TSB spec I have calls for adjusting the distance between the brass ferrule on the cable and the end of the adjuster sleeve. If the kickdown cable has ever been replaced then that ferrule is arbitrarily clamped on by the installer and no longer a reliable point of reference. The way most Volvo Vista Techs do it is as described in the FAQ. While plucking and releasing the kickdown cable, starting with the cable slackened, you adjust out the sound of the clunk where the metal pawl on the end of the cable can be heard striking the bottom wall of the kickdown chamber in the trans. You need to do that in a quiet area. It's best to keep track of the number of nut faces turned from the original adjustment position in case you have difficulty and need to get things back to where they were.

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

|

|

|