|

|

|

Hi all, it’s been a while. My trusty old 1987 240 is living a sheltered life these days and is now winterized and put aside until spring, as is the old motorbike.

But before this, the speedometer started acting up. Sometimes, but not always, the speedometer doesn’t give any readings for the first few minutes. Then, all of a sudden, the needle will jump up to show me what is assumedly the correct speed. If I hit a bump, this will fix it. Once the needle is active, it will be okay for the complete ride. It will only be sticky from start. I believe my speedometer is driven from the diff, not from the transmission.

Does this ring any bells for anyone? Is this a known problem with a hopefully easy fix?

Thanks,

Erling.

--

|

|

-

|

|

|

Okay. I've had a look. Hm. Before I can do anything, good or bad, I need to get the car up on ramps and start the job with degreasing. Like everything else under the car, also the sensor is covered with layers upon layers of antirust treatment. Seems like a job for April.

Erling.

|

|

-

|

|

Hm is right. I don't believe I would disturb that rustproofing. Let me think about an alternative to invasive exploratory surgery as the first step in diagnosis...

--

Art Benstein near Baltimore

Does running from my responsibilities count as cardio?

|

|

-

|

|

|

my 87, has a speedo that jumps occasionaly when I first pull it out of the garage.

This started years ago after I removed the cluster to fix the hinkey Temp Comp board. Having only removed the clusters from cable driven speedos, I was a bit ham-handed with the newer wired connection. Not knowing that there was a 'tamper guard' on the connection, I mangled the tab.

When I put the thing back together, the connector held, but there was this bounce.

Reaching back I wiggled the connector to make sure it was firmly attached, the bounce stopped, but returns every once in a while.

Much later, I saw your Clean Flame Trap photo series on removing these clusters, and saw the tab I damaged.

Uff Da...if only...but then those were the dial-up modem days of the net. 2400K and I wasn't on it much. I got the tip about the Comp Board reading IPD's newsletter and catalogs.

So to the Poster---have you had the cluster out before??

|

|

-

|

|

|

Interesting, CeeBee1. If my memory serves me right(!) European cars don't have the Temp Comp board, and I'm in Norway. But I have indeed had the instrument cluster out. Certainly for swapping the clock for a tach, possibly for replacing bulbs. But that must have been at least 15 years ago, and this speedo behaviour started only a couple of weeks ago, just before I put the car away for the winter.

|

|

-

|

|

"If my memory serves me right(!) European cars don't have the Temp Comp board, and I'm in Norway."

I'm in the Netherlands and both 1992 245s I've owned have it. In the normal operating temperature range, the needle is kept at a steady just below half scale ("43 minutes") reading until temperature increases above a certain level. But by then the viscous coupling will already have engaged the fan.

Without the temp comp board, the indicated coolant temp would be fluctuating all the time. The meter in my Amazon did this and that would drive me nuts in hot weather as the needle would touch the red area on the meter regularly. This made me worry, but it never actually came close to overheating, I just kept thinking it did.

|

|

-

|

|

|

Your wiring at the speed sensor on the rear axle needs repairing. Insulation of the wiring gets old and cracks. My 1989 740t was having the same problem until I cut open the sleeve of the wiring harness at the rear axle sensor and insulated the bare wires. Works.as.it.should now.🚧

|

|

-

|

|

You don't have to be "ham handed" to break that security device. It is made to be broken by anyone attempting to remove the connection to the speedometer, assuming only the dealership tech will have a replacement clip. Makes the the device tamper-evident.

I've not yet felt it was necessary to hold the connector in place, but I have heard credible opinions to the contrary. It wouldn't hurt to unlatch the terminals in the L-shaped plug and add a little tension to them if they don't grip the circuit board fingers, but I advise against adding solder to the fingers to accomplish this. The soft solder just squeezes out over time.

This connection would, in my experience, be the second most likely spot to create an intermittent speedometer/odometer, but normally it responds to a whack on the dash above. In any event, as with any symptom which cannot be reproduced on demand, it will take a while to prove you've changed it. So the whole pursuit may be best left for April.

--

Art Benstein near Baltimore

Nobody sees a flower - really - it is so small it takes time - we haven't time - and to see takes time, like to have a friend takes time. - Georgia O'Keeffe

|

|

-

|

|

|

Now you've got me thinking that the initial needle blip ---when I back out of the garage first thing--- is because I'm in reverse, the slight shifting is a sign that the rear connection to the sensor may become a problem in the future.

I'll check it out when I do my annual pre-winter Fluid Film(which is now carried by Lowes $9.99 a can)spray job on the under side later this month.

The Cat's Pajamas

https://www.fluid-film.com/automotive-applications/

Lanolin based. From hand-rubbed contented sheep.

Our sheep massagers have the smoothest hands.

|

|

-

|

|

|

Hi Art,

It interesting that you have commented on the idea of soldering the traces on that connection, when I can honestly say, that you have recommended remelting solder joints due to cracking or flux corrosion.

Cracking doesn’t seem so soft to me or at least not as soft as the copper on a plastic film on top of a fiberGLASS substrate. So your point is, there’s a softness there and with the prongs I guess!

As far as solder being soft, it’s not really so, as it’s a mixture of other metals like tin for an example and it’s another science to some extent, that’s taken for granted.

Today we are trying to find better alternatives and we have seen those results have pan out in many areas besides in relay boards.

Warning! I headed into a story, look out!

Plating copper with another element is common place or at least it wasn’t in the early seventies.

When I, an E4, in the Navy, I was given two bottles of solutions to use to plate over the top of an AC generators copper slip rings.

A bottle contained an ion solution of Rhodium.

At that time that quart bottle of Rhodium was $600. No idea how much but I was electroplating. Neat stuff!

We then added on a thinner coating of gold on top of that. I believe gold was the cheaper element?

Since we were underway, at the time, I wasn’t going anywhere with it!

I also got to watching the solution moving in the pan.

I experienced my first Sea sickness.

I was told by my seniors, DON’T WATCH the liquid, but don’t let it spill either?

I knew why I got the job! Some sailors were sick-o’s in several ways!

The whole purpose of this procedure was to create a wear surface on top of the copper.

A final gold treatment was applied as to wear into the carbon brushes for lubrication, let alone the conduction.

Today carbon brushes are made with a great deal of different mixtures for special purposes.

It is a science all to itself.

If you want to know more about carbon brushes try this site.

https://www.mersen.com/uploads/tx_mersen/5-carbon-brush-technical-guide-mersen_07.pdf

I have known about them since the mid eighties.

I worked on a steam turbine deck in Long Beach for So. Cal Edison. I got to crawl around in between the windings, the outer housing of a GE AC dynamo installing a modification of steel belly bands

to help keep the windings from ringing. Some design revision that was!

I was a lot thinner then and I was volunteered, if I wasn’t Claustrophobic!

Guess I hadn’t learned from my Navy days!

I was a natural for it though, as right after I got out of the Navy, I worked for a company that machined three Dynamo housing for Westinghouse, in NY!

They went from there to a new Dam in Brazil of the mid seventies.

I imagine those dynamos are obsolete by now!

Metal plating over a softer substrate is common place. Look a the passing “ART” of chroming things!

Brass and copper helped seal the deal against ferrous metals.

Lead was used to make car bodies straight before BONDO polyester fillers.

Lead has been a double edge sword for humanity for quite some time!

Solder is more readily available to us to use than Rhodium or gold so I suggested it as a bed for those clam shaped prongs.

Yes, adding more tension is a wonderful suggestion but you are slipping the contact right back onto a compressed copper and plastic substrate that is as tired as those prongs.

I was thinking that that surfaces needed a plating job to rebuild the valleys or depressions.

If the solder is as soft as you I and I imagine the prongs will be in a trench.

To me that creates a better contact surface connection irregardless of tightness that’s going to restart is progress all over again.

It just something to try, since we don’t have Gold and Rhodium in our pocket books, like the Navy contractors did!

Tricky things have always been done with the taxpayer money.

Right along with many a turned heads, under wiggled eyebrows and winked eyeballs!

Luckily, these old cars can show us that things need not to be so complicated.

The 240 had a good bunch of thoughts come together!

I wish and think, that the transition over to less fossil fuels can be done a lot simpler, if we think harder and plan better!

We have lost our way in wars, because of underground tenacity and when simplicity’s are sought it can do everything better.

For a wisdom adage,

A thin coating, underneath can go a long ways, every time!

Cutting tools with their coatings have revolutionized the production of products!

Sorry about the long story, but hey, it’s Veterans Day!

I felt that My horn needed some tooting!. I have no kids to care.

Phil

|

|

-

|

|

"Solder is more readily available to us to use than Rhodium or gold so I suggested it as a bed for those clam shaped prongs. "

Sorry Phil. I posted my advice before I followed your link to see that it was you I was contradicting.

--

Art Benstein near Baltimore

"Why is a birthday cake the only food you can blow on and spit on and everybody rushes to get a piece?" -Bobby Kelton

|

|

-

|

|

|

Oh that’s ok Art, that’s why it’s called a forum!

I have realized that I’m not all knowledgeable from my ramblings, but Once you post, its out there!

I made the statement about the shape of the prongs being like a clam but I believe now they might be more like a lobsters claw!

Don’t clams live down a hole in beach sand?

Oysters are flat disc like animals!

I have only fished or hunted, one time each, in my life, so I’m sure there’s someone out there could tell me a thing or two. (:)

One being, For person who keeps their hands greasy black shouldn’t go fishing without proper tools either!

I’d say, to-shay about working in electronics, as you do. You know what you know!

I have a great respect for your work let along in having your own dedicated web site too!

You and Jarrod are providing us all with a need to read and for some to write, as best as we can!

The avenue of learning has always been a two way road with intersections!

Phil

|

|

-

|

|

Phil,

I don't know about clams and oysters. Fact is, three of my friends and I spent three days this past week shucking and eating raw oysters (and clams) and we still couldn't arrive at a consensus describing the difference in experience. My take was the clams offered a few more chews and were most assuredly more adept at keeping their shells on. I can't draw the analogy to the card edge terminals Volvo used at the tail lights and speedometer. Those connectors I could shuck without an oyster knife.

In the mid-60's coating the card edge fingers with solder was already known to be unhelpful. I'm not sure why exactly, but I suspect it is the quick oxidation formation on solder plating which was used for the rest of the circuit board and still is. The fingers were always masked during the solder plating. It is all about contact resistance and force (tension).

In the late 60's, gold was used, and then in '68 the gold price started climbing. Engineers don't dictate design; they have bean counters to compromise. Electroless tin was chosen as a substitute when the accountants prevailed, and when the application wasn't safety critical. You'll notice the gold on the airbag connectors.

That savings of nickels and dimes almost ruined the reputation of the manufacturer (Motorola, Inc) where I was employed then. A whole product line of radios needed to be whacked when they quit working in the field, whereas the prototypes had gold inter-board connectors. I can't stop whistling the theme song to Goldfinger today thinking about it.

The thing about an oxide layer between most contact metals is its breakdown voltage. High voltage rarely has a problem with it. Small signals, such as the voltage developed by the differential sender (reluctor) won't penetrate even very thin layers. Think of how popular DeOxit is with electric guitar players -- those are low level voltages. Yet aluminum develops a seriously impenetrable dielectric layer even mains voltages can find trouble piercing, hence the zinc pastes like OxGard and NoAlOx prescribed to prevent contact resistance fires.

I have kids, and I remember showing them how to make their Nintendo cartridges work again. Here's a youtube https://youtu.be/ecoxUwzyc0Q I could have used back then. :)

--

Art Benstein near Baltimore

Was ist Übergangswiderstand?

|

|

-

|

|

|

Hi Charlie and Art!

I can agree with both of you on waiting on digging under that gunk of waterproofing!

I agree to check out the connector to the speedometer on the back of the instrument cluster, whether he or someone else, has been into it or not.

I have been suspicious of those prongs in that connector before.

I addressed it in this thread below with other Bricksters as a possible issue maker.

https://www.brickboard.com/RWD/volvo/1679463/220/240/260/280/1991_240_speedo_needle_drops_0_jumps_back_dash_tapped.html

If he hasn’t done this and/or or isn’t aware of the temperature compensating board modification, this would be a good time to initiated!

I think there is another recent post “somewhere” that asks the question about what voltage come out of or goes into the differential sensor?

Maybe you guys can look for it as I’m curious how that works as well!

Phil

|

|

-

|

|

Hi Erling,

Sometimes you can nail this one just by a look at the wiring where it leads to the sender in the diff. The wires between the connector in the trunk and the sender on the differential are those high-strand-count silicone-insulated once-flexible and special wires made to survive bending and flexing. After a number of years, the silicone insulation falls apart, either shorting the wires to each other or ground, or no longer supporting the wire inside causing a break.

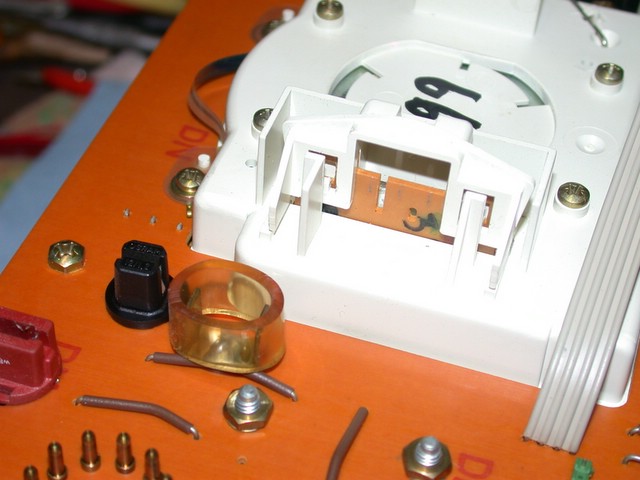

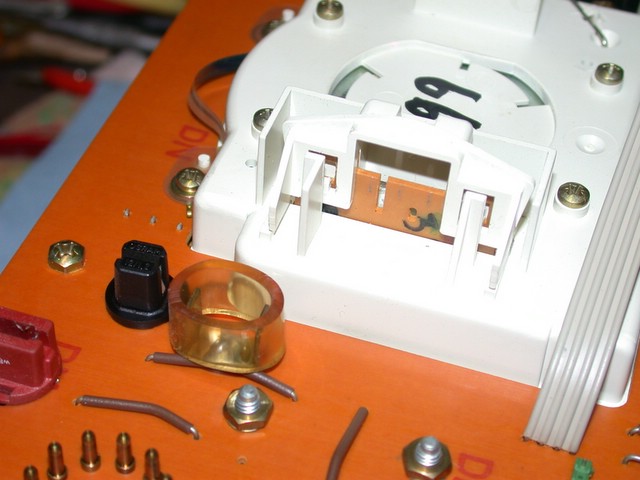

These pics are from a later car with ABS, but the principle is the same. Then, if you have a look and it seems the wires are in good shape, I've done some further diagnostics to find a loose connection at the back of the speedometer itself:

http://cleanflametrap.com/speedoDiag.html

Note, in the above link, an AC transformer is used to substitute for the AC differential signal, and those are really getting scarce, even in my junkbox. In fact, many DC power supplies are labeled "AC Adapter" so it is easy to be misled about which way the greenies go and how quickly they change direction (50 times a second where you are). I have another method using a smartphone to generate the signal if you get to that point.

--

Art Benstein near Baltimore

"In the midst of winter, I finally learned that there was in me an invincible summer." -Albert Camus

|

|

-

|

|

|

That's great info, Art, thanks. Once we get a slightly warmer day than today, I will crawl under the car and investigate. Hopefully the wiring will be repairable if it seems dodgy, I doubt that I will be able to find a new one.

Erling.

--

|

|

|

|

|