|

|

|

Hi,

1994 940. So we have heavy traffic around here, so I am frequently on the brakes. As a result, my third brake light housing has melted. I am looking to source a new housing, but I was wondering if there was an LED or other heat-free kind of light bulb that I could use as a replacement for the standard incandescent.

Thanks.

|

|

-

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

There's LEDs for almost all auto applications.

A small LED flat panel with adapter might be a good choice for the high brake light. There's a wide selection at at ebay.

One hiccup is making the bulb out sensor happy for brake lights.

You can work around the bulb out sensor if you don't care about the alert for a dead lamp.

The good news is that the prices are very cheap now and you can test them out

without breaking the bank.

Bill

|

|

-

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Thanks for the responses! I wonder if it is possible to use some sort of heat blocking material above the bulb. In the old days, this would be asbestos. I wonder if there is such a material that would block some of this heat from melting the housing.

|

|

-

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Dear U.S. Diver,

Hope you're well and stay so! Yes. In the plumbing section of a home improvement store or hardware store, you should find a fabric heat shield used by plumbers, when they have to use a torch to braze or to solder near wooden joists, rafters, beams, etc.

See: ttps://www.homedepot.com/p/OATEY-9-in-x-12-in-Hands-Free-Solder-Heat-Shield-314002/100345508 . This shield can tolerate direct flame, up to 2,500°F.

I've never had to cut one of these, so do not know: (a) if the fabric disintegrates if it is cut; (b) what tool is best used to cut this fabric; (c) whether a small piece of this fabric can be shaped to fit around the bulb.

Hope this helps.

Yours faithfully,

Spook

|

|

-

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Hi Spook. Another good option is aluminum duct tape. Heat proof (leastwise for the kind of temp we're talking here), can easily be cut to fit, shiny to reflect more light. I hadn't noticed that black Oatey heat shield before. A lot more expensive than duct tape, which I always have on hand. I've got a scrap of old fibreboard I use when soldering between joists/studs, especially with a regular torch where I have to hold the heat longer, whereas my mapp torch works faster. Probably asbestos, so I heavily sprayed it with barbecue heat paint to hold the fibres.

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

-

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Just to close the loop on this old thread, I did replace my third brake light housing (Genuine Volvo, $38) and I put a strip of 3M Flue tape on the inside. Not so sure it will insulate so much as it may spread the heat out beyond the 1/2 square inch.

Will it work? Time will tell. Thanks, all.

|

|

-

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

I've successfuly switched both my 940s to LED taillighting. Everything is significantly brighter. Just doing the backup lights alone is worth the cost and effort.

There are a number of brands out there and prices vary from expensive to less than the price of incandescents if you buy from the likes of Aliexpress and Temu. Just be sure to pick ones that have a decent number of SMD LEDs pointing backwards, not all pointing out the sides.

My personal choice for brakes was the Auxito 1157 with the five SMDs on the end that others have recommended here (there are other Auxito 1157 designs I haven't tried that may work as well or better), which you can often get for under $10/pair directly from Auxito in China incl. shipping. Always get the LED colour that matches the color of the lens it's behind, otherwise other wavelengths are filtered out and the bulb won't be as bright as advertised. For the dual element 1157 bulbs, almost any LED will have the park light element considerably brighter (a perpetual problem with our Volvo reflectors, especially as they age). In general, the brake light element is also brighter, but not twice as bright as the park light. Bulb running temperature is of minimal concern.

As for the bulb sensor, after a few growing pains I've now got no problems. For the first few months the bulb warning light occasionally went on for short periods, so start by cleaning up the holders, taillight assembly contacts and loosen/remake the black ground wire at the chassis, ideally using a suitable electrical paste. Even after doing that, I occasionally had intermittent warning bulb issues until I re-flowed the solder joints in the bulb sensor relay, paying special attention to the brake light circuits on the middle board. For many months now everything is working fine in both 940s.

Note that if you use LEDs in taillights then ideally you will also do the 3rd brake light to help minimize bulb sensor issues. The bulb sensor design compares the current of one brake bulb to the combined current of approximately 2/3rds of the other brake bulb plus 1/3rd of the 3rd brake bulb. When that comparison becomes significantly unequal then the reed switch trips and the warning light goes on. If the two main brake bulbs are well matched without significant voltage drops through the wiring and contacts then an incandescent 3rd brakelight seems to work fine, but obviously you're pushing the balance of the reed switch, so highly recommended to use an LED 1156 3rd bulb.

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

-

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

That's interesting!

"The bulb sensor design compares the current of one brake bulb to the combined current of approximately 2/3rds of the other brake bulb plus 1/3rd of the 3rd brake bulb."

I wonder how it does that.

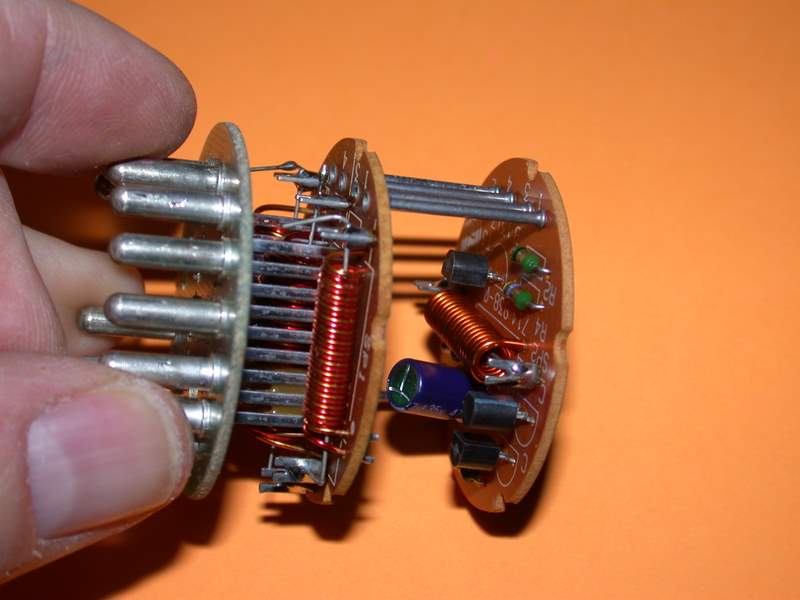

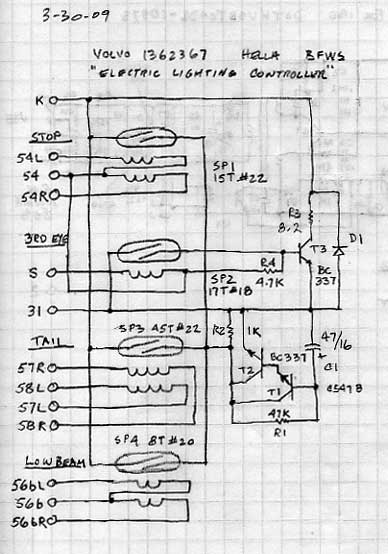

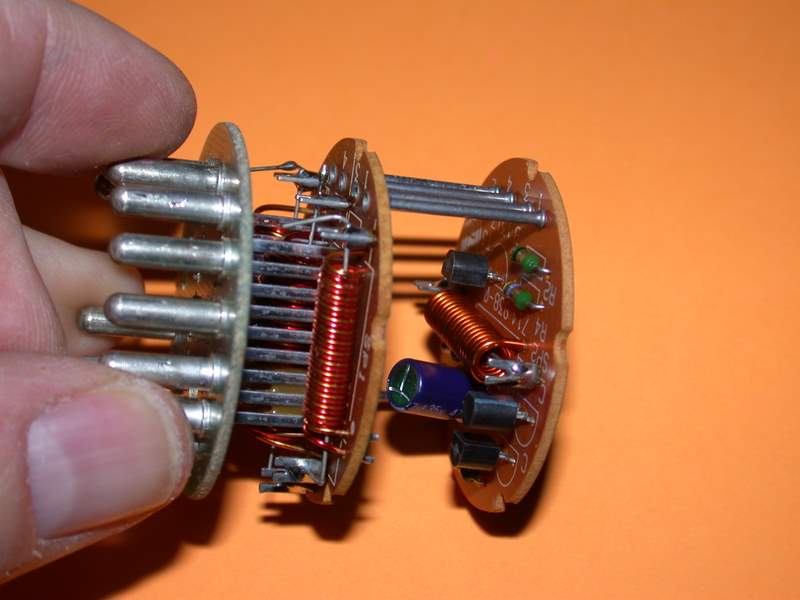

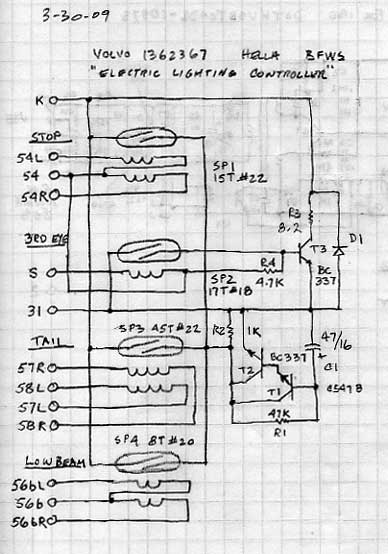

The 240's sensor, p/n 1362637 looks like this:

The way it works for the third brake light is a logic circuit: If it senses voltage applied by the brake pedal switch, but does not see current through the high-mounted bulb, it lights the bulb failure indicator on the instrument panel.

Or, if the two brake lamp filaments in the tail lamp clusters are pulling current unequally, the warning is given.

The windings around the reed switches which turn on the warning lamp are chosen to match the expected current drawn by the incandescent bulbs as much as 15 times more than some LED equivalents use. See the fine wire used in the running lamp (rear parking lamp) and the heavy wire for the brighter brake lamps and low beam headlamps.

Each has two windings in reversed direction, so that two equal currents cancel the magnetic field that closes the reed switch, except for the third brake light which has only one winding to sense the presence of bulb current.

The logic for the brake light warning can be tricky. Let's say you pull the connector off of both tail lamp assemblies, simulating both sides having failed filaments. No warning. Yet the third brake light works. Let's say your brake lamp fuse opened up. No warning.

However, if the lamps are changed to LEDs that do not draw enough current to operate the magnetic reed switches -- no warning. Same as both sides having failed incandescent bulbs. But some LED replacements include resistors for compatibility with CAN bus cars, and may draw enough current to work with this bulb failure warning sensor. Or maybe. On the hairy edge of unreliability.

So, however the sensor used in the '94 900 series cars works, if you want to have that warning system, it might be good to test it by removing one of the LEDs, because although it was a feature to warn of broken filaments, we with old cars have seen just as many bulb failure warnings that were caused by poor and corroded connections, to which LED replacements are just as prone.

--

Art Benstein near Baltimore

|

|

-

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Hi Art,

Correct me where I'm wrong here.

Note in your schematic the 3rd brake light inductive coil on pin S doesn't have an opposing coil on the reed switch. If the brake lights aren't being activated by the brake switch (pin 54) then there's no current in that coil, the reed switch isn't tripped and the warning light is out, like it's supposed to be. Now if the 3rd brake bulb is burned out there's also no current through that coil, so what in your schematic now activates the warning light? I've always assumed there was a separate reed switch added for the 3rd brake light with an artifical current in an opposing coil that had a resistor on it rather than a bulb. My recent inspection suggested that's not the case, leastwise in the one I just checked which may be a slightly revised design from earlier red ones.

In the one I recently examined (I'm too lazy to go remove and crack it open for a pic), there was only one reed switch for the combined brake lights. Surrounding that reed switch is one full coil for one brake bulb and there's two partial opposing coils, a small one (for the 3rd brake light) inside a larger partial one (for the other brake light), both with fewer windings than the larger coil. You have to look closely to see that extra little inductance coil. When current is running through both of the two partial opposing coils it then matches the magnetic inductance of the larger coil to keep the reed switch from tripping and no warning light. If any of the three coils carries less current than normal (normal being all bulbs on or all bulbs off) then the reed switch trips and you get the warning light.

The LEDs used in 12V-14V automotive applications generally need a resistor, either an internal one or an external one added to the circuit. Many have some kind of internal voltage limiter to handle voltage spikes. CANBUS bulbs have added circuitry with internal resistors and more stable voltage/current limiters to work with bulb sensors, electronic controllers and dimmers. The Auxito 1157/1156 LED taillighting I'm using does not need an external resistor and was not listed as CANBUS compatible. The Auxito 9004 LED headlights I'm using also don't need an external resistor, but are listed as CANBUS compatible and having internal thermal sensing circuitry so as not to fry the LEDs and transistors with both current limiters and an internal variable speed fan for cooling. These 9004s are still advertised as possibly needing a CANBUS isolating adapter with non-CANBUS cars in case of bulbs blinking or bulb sensor problems.

I usually noticed these intermittent bulb sensor problems for a few minutes during warmup after starting up driving or during cool down soon after coming off freeways after long drives. Sunny warm days are worse than cloudy cool days. Hot summer days parked out in the sun were especially bad. Keeping the contacts, connections and grounds all spotless and making sure the solder connections in the sensor are all in top shape has helped keep these intermittent problems at bay (until one 5 minute episode yesterday, I've had no bulb sensor problems for many months).

I'm now working under the assumption that what's been intermittently upsetting my bulb sensors (two 940s) is subtle variations in the currents through these LEDs as the internal circuitry unevenly warms up and cools down. While compact fluorescents get brighter as they warm up, LEDs get dimmer as they heat up and try to limit the internal voltage and temperature. Proper LED headlight specs should give separate startup and running lumens, but most mfrs opt to advertise only the startup lumens. If the bulbs thermal response is the same left/right then everything is okay, but if it varies left/right such as during warm up or cool down then that difference may be enough to momentarily upset the bulb sensor. Different bulb sensor designs may be more sensitive than others. Using CANBUS isolators would likely eliminate my intermittent problems.

So, I ask, why is our bulb sensor design seemingly more sensitive with lower current LEDs? Why is it seemingly always the taillights, not the much higher current LED headlights? Is it unbalanced left/right current that's temperature related? Do reed switches trip based on an absolute difference in current (eg. 1 Amp) or do they trip based on a proportional difference (like 10% of the Amps). If it's proportional then that might explain why they become more sensitive as the current gets lower. Eg., a .9 amp difference in a 2 amp circuit would be much more significant and trigger a warning compared to a .9 amp difference in a 10 amp circuit. I'd have to really bolt down my thinking cap to start wrapping my brain around thoughts of the strength of opposing magnetic fields inside an inductance coil under different conditions as well as the magnetic response of these little reed switches under different conditions.

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

-

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

"...what in your schematic now activates the warning light?"

That's easy. T3 is forward biased through R4 and supplies a return for the failure indicator at K. But that's the 1362367 sensor used in the late 240. I have no idea what's in your car.

"So, I ask, why is our bulb sensor design seemingly more sensitive with lower current LEDs?

Again, can't say about the 940, but your one-third two-thirds hypothesis was certainly interesting. Part number?

As to reed switch pull-in current, that depends on the number of turns and current, which for the 240's circuit I do know, is matched to the expected load. If not enough load is present, because of the LED's reduced demand, the reed switch won't close.

--

Art Benstein near Baltimore

|

|

-

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Some really good suggestions, here, thanks, all!

|

|

-

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

here's the LED panels that would work for you

https://www.ebay.com/itm/283975046870

They can be hooked in parallel with the supplied connectors

Maybe two would be OK for the center brake light.

Use them elsewhere for interior lighting.

Filament bulbs are obsolete.

Bill

|

|

-

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

New bulb holder/backing plates are still available new for $40.00.

LED bulbs for any of the brake lights may make the bulb warning system not to work correctly.

The style of 3rd brake light bulb is very common and you should be able to find the LED equivalent at just about any auto parts store.

Unfortunately, melting plastic is not an uncommon problem for the brake light bulbs and I strongly suggest that whenever possible like when at a full stop while waiting for a traffic light to change, waiting for train or while going through a drive through, to pull the parking brake lever and get off the brake pedal.

That's what I do when driving my or anybody else's 1973 and later rear wheel drive Volvo that we work on.

--

Eric

Hi Performance Automotive Service (formerly OVO or Old Volvos Only)

Torrance, CA 90502

hiperformanceautoservice.com or oldvolvosonly.com

|

|

-

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

When you say "New bulb holder/backing plates are still available new for $40.00" do you mean the whole plastic brake light housing, or just an interior part of that? Thanks.

|

|

-

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Just the part that holds the bulb.

Do you need more than that?

The whole assembly might be available.

--

Eric

Hi Performance Automotive Service (formerly OVO or Old Volvos Only)

Torrance, CA 90502

hiperformanceautoservice.com or oldvolvosonly.com

|

|

|

|

|