|

|

|

AW-71L failed (reverse only) after being put into reverse with a racing engine (2000 RPM, due to bad vacuum leak). First and all forward gears drive fine, except engine RPM at 65 mph highway speeds is about 1000 RMP too high. Overdrive solenoid switch works fine from from 3 to 4, but RPM seems excessive in overdrive (trans not slipping).

Cannot believe that strain from shifting hard into reverse about 3 times at 2000 RPM would cause loss of reverse only, when 1st gear is fine and responsive.

Could a trans valve body ball blockage cause this? Or is a govenor pressure solenoid (or pressure sensor) implicated? I don't know what activates reverse gear.

Has been driven with full synthetic fluid and clean filter the last 50 miles, so I wouldn't normally expect dirty fluid to be the problem.

Sure need reverse back!

|

|

|

|

|

Hi,

If you just change the oil and now have driven it, you are probably only low on fluid.

As little as a half a quart can result in improper shifts or more on a drop out of reverse not working.

Your transmission might be even be a “lock up” converter type in the 900 series.

I only have 240s so I have no experience in them. I have only heard of them and never drove one, that I known of, in any car.

What you thought was on the full mark has now stopped up inside the transmission in what was an emptied cavity.

The valve body is full of them let alone getting the torque converter chamber topped off.

Make sure you have driven the transmission about eight miles and while parked select all the gears while stopped. Do all that just before reading the dip stick for an accurate assessment.

On lots of automatics transmissions when there is a problem with going into the reverse gear it’s because of a low fluid issue.

It’s the first sign that tell mechanics to check it right off the bat.

Hopefully it want be a bunt! (:-)

Phil

|

|

|

|

|

Thanks Phil, hope you are right. After oil change I drove it about 15 miles, then checked oil level while at operational temperature, engine running, in park. At that time the level was correct. And, at that time, reverse worked fine.

To your point, when I changed the oil I was impressed at how much residual oil was still dripping even a couple days after droping the pan and removing the trans filter. Also, I had done the trans fluid flush using the radiator trans cooling lines, so yes, a lot of fluid got displaced, which could leave voids throughout the system. Tomorrow I will drive it at least 10 miles down Interstate, and check levels again on a flat driveway. May be pleasantly surprised to verify low trans fluid, potential easy fix. Thanks for that input, will let you know what happens!

If not that, I will have to learn how fluid flows in the valve body to engage reverse. I may also have a separate lockup solenoid failure that could account for the higher than normal highway RPMs both in and out of overdrive. At speeds above about 50 mph the lockup solenoid is supposed to kick in, locking the torque converter, giving you a solid connection like in a manual transmission.

Not having much luck with finding an AW71L transmission rebuild manual, or good descriptions of the lockup solenoid, govenor pressure sensor solenoid, or govenor pressure solenoid. Rock Auto shows a couple of shift solenoids, not available, of course pricey ($300).

|

|

|

|

|

I may not be a trans expert, but I am good at sleuthing.

First off, if you haven't found it, be sure to check out the FAQ feature article here on AW7x Rebuild

https://www.brickboard.com/FAQ/700-900/TransmissionAutoRebuild.htm

also the one here on valve body service

https://www.brickboard.com/FAQ/700-900/VolvoAW7XValveBodyService/AW7Xindex.htm

Here's a link to a Volvo Service Manual that covers the AW71L

http://www.krona74.ru/library/Auto/Automatic transmission aw70-72l.pdf

Here's an earlier Volvo Service Manual that may also be of interest that covers up to the the AW71 trans, extremely similar to the AW71L except for the valve bodies and torque converter being slightly different

https://www.240.se/litteratur/tp30868_2.pdf

Any AW72L manual you find will also be useful. Those were used with Volvo's B234F 16-valve engine of similar vintage. Only the lower gearing and valve bodies were supposedly different.

There was a good AW71 rebuild discussion over on Turbobricks here with good pics and comments related to such failures as yours.

https://turbobricks.com/index.php?threads/late-model-aw71l-disassembly.243382/.

An AW71L rebuild kit can be found here

https://www.oregonperformancetransmission.com/product/OPT-AW71L-RB.html

It doesn't say it's for the 900s, but I don't know why it wouldn't be. At over $300 it's not cheap. If you can't find a cheaper source then a good used one may be a better option when you consider the time saving and the odds of doing it right as a first time effort.

Toyota used these same transmissions, so follow any links you find into Toyota user groups and references.

It's a rare day on the brickboard when we hear of a serious trans issue such as this, not just sluggish behaviour. I'm crossing my fingers for you that it's the fill level, but based on your comments of a run-in followed by a top-up, I can't say I'm overly hopeful if you filled it to max, not just min. Smells like valve bodies to me, but again, I'm no trans expert.

Please keep us posted of your progress.

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

|

|

|

First Dave, thanks a million for the transmission manual links--best source I've seen yet. You saved me a lot of time having those references.

My hopes for simple fluid level check proved not simple. Level is normally checked at idle in park or neutral with trans at full operating temperature after driving 10+ miles, which I just did. Unfortunately, impossible to get an accurate read because the engine is now "idling" at 3000 rpm and makes the dip stick wet well above the hot max fluid mark. With trans still hot and car sitting 15 minutes with ENGINE OFF, fluid level is 3/4 inch ABOVE MAX. Not accurate test, but may well indicate overfill.

So now have to run all the traps to get idle corrected, the first being replace the O2 sensor (pulling fault codes for being far too rich and bad O2 connection). So it's hurry up and wait for new O2 sensor to come from Amazon. In the meantime, will check throttle body clearances, linkage, accelerator cable, and make a smoke machine to find what appears to be a significant vacuum leak. Once idle corrected, then can accurately read trans fluid level at correct idle. Seems to me that very fast idle also will effect govenor pressure sensor output, and consequently improper pressures to engage reverse and torque converter lockup.

Just wondering, WHAT WOULD HAPPEN IF IT TURNS OUT THAT TRANS FLUID IS SIGNIFICANTLY OVERFILLED?

Thanks again for references and comments.

|

|

|

|

|

Like Phil says, you've got to get that idle under control before you go much further. Something's seriously out of whack to idle anywhere near as high as 3,000, even 1,300 rpm.

a) Have you been doing any work or adjustments around the throttle body or on the intake side?

b) Is the throttle able to close? The tip of the adjusting screw should be touching the stop. The throttle plate could be binding in the throat. Check at the throttle spindle to make sure the throttle cable from the pedal and the kickdown cable to the trans are not restricting travel and that both are properly seated in their grooves in the spindle.

c) Can you hear the throttle position switch (TPS) click just as you begin to manually open the throttle and again just as you close it?

d) Are the connectors properly seated on the TPS and idle air valve (IAC)?

e) Is the wire to the engine coolant temp senser (ECT) connected? The ECT is below the intake manifold, back between runner #3 and #4.

f) If there was unmetered air to get that high then I'd expect a very poorly running engine. Is that the case? Check that both hoses on the IAC are connected and not split. Check that the accordian intake air supply hose isn't split in the folds, especially check underneath. While you're at it, check the PCV hoses on the throttle body, flame trap and that the flame trap is properly connected to the oil separator box.

g) If all that checks out, then you need to start diagnosing, beginning by confirming TPS operation and that the ECT is providing a proper reading.

2) As for overfilling the trans. It's not at all good for the trans if run that way for any great time and can cause serious damage. Fluid flow is affected and can cause shifting problems, such as slippage between gears and rpm. The trans fluid will foam up and thicken, possible forcing fluid out of the pan and other seals, providing poor lubrication and fluid flow, with gears overheating and eventually damaging all kinds of things. Trans fluid level can be checked cold, it just won't be accurate and will read a bit low.

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

|

|

|

not very scientfic but i had all sorts of weird running issues and eventually found that I had a stuck open fuel injector. I pulled the fuel rail and connected the ground wires back up, unhooked the coil high tension so ti couldnt fire, and then laid down some rags, turned the key on craned a bit the injectors sprayed. then key off.

in mine one injector was spraying a steady stream like a squirt gun and would not shut off so it was dumping the fuel rail into cyl 3 upon every shutdown.

careful of the fuel and fire hazards but I'd try that just to make sure the injectors seemed to sort of be acting normal. make sure you have the O rings for the fuel rail before you yank it. that test shouldn't take long and shouldn't affect how it runs, weather or not it will find an issue , maybe not, it is likely a problem elsewhere, it is a thing you can verify without buying parts.

like you it was a thing driving me crazy and I was all over the place trying to troubleshoot it so I'd check that sooner if I had such issues again. one tip off was getting white cloud for the first block , because cyl 3 was not firing until the plug dried up enough. another clue was that plug 3 was wet, funny the plugs looked kind of OK until finally i found one black as soot and then checked the injectors. I think the plug may have been cleaning itself or maybe the injector issue just had to get a lot worse before I figured out my issue. i believe you could have an injector issue that is less severe and maybe not as obvious as mine was when I finally got it solved. I think it had been worsening gradually prior.

you might find an air leak or something.. if you can connect a gauge you can check fuel pressure, maybe a bad fuel pressure regulator. the fuel pressure regulator or idle air valve are easy to swap so is the Air Mass meter, so you could borrow those from your spare car Just to test.

the oil separator is one thing but also above that hidden in the nest of hoses should be a little plastic cap thing with small holes - the flame trap. they can plug and cause high oil pressure that can pop out the oil seals, so if you are in there its worth cleaning that out. It might be different in different years but to the uneducated, it's well hidden so it gets ignored.

on my 740 the fuel pressure regulator is at the front of the fuel rail and connects tot he manifold for vacuum. If you pull that line off , see its good fit and if gas comes out of that hose it means the FPR is bad.

the plug connector on the AMM might get green from corrosion I'd have a look at that with a flashlight, maybe give it shot of deoxit reseat it a few times to try to clean the connectors.

my theory is that you are seeing some conditions where it is running pretty fast, and yes idle can get wrong by an air leak, but then it will be running lean. Is there enough fuel entering then to race the engine at idle at 3000 RPM if the only problem is an air leak? i am thinking you'd need extra fuel for it to run that fast and not just a lean mix. maybe if an injector is stuck or similar that would provide extra fuel? It's just thoughts, not anything concrete.

reading the color of the plugs could help. maybe pull the when its running like that and see if they look like its running lean or rich. see if any look different or odd, Just good to know.

I have an old tool called "colortune" kind of interesting , its for tuning carbs but it's like a spark plug with a clear insulator and with that I can see the color of the burn inside the cylinder. the idea is that you can check the color of the "flame" and use that to adjust the carbs equally..

I dont know how common they are. kind of an unusual tool that i rarely use but maybe it could show a lean or rich mix or problem like this.

I found a link to it, seems they are still made.

https://www.gunson.co.uk/techtorque/Colortune-See-inside-the-combustion-chamber

a mechanic would probably have access to a CO tester and a fuel pressure gauge and I dont have either. you can find stuck open injector issues by doing a leakdown test on the fuel rail, and avoid spraying raw gas all over and avoid that obvious fire hazard.

|

|

|

|

|

Amazonphil,

Thanks for the additional ideas, adding them to my checklist.

Tomorrow is big day to pull apart everything around the throttle body.

What I've learned so far:

Idle speed is important to transmission function. RPM influences trans govenor fluid pressure, as does proper adjstment of the trans kickdown cable. REVERSE requires 50% MORE pressure to engage than the forward speeds! Plan to pull trans pan, check for crap, may pull trans valve body (ugh), at least flush trans fluid and change filter.

Got fault codes 113 and 231, implicating failed O2 Sensor. Replaced it today, only difference is now the engine "idles" at 3200 instead of 3000 rpm!

Discovered Throttle Position Switch does not click, so it is out of adjustment or worse.

Trans kickdown cable is out of Volvo manual spec for length when accelerator fully depressed.

Spraying carb cleaner around all hoses, brake booster, intake manifold, turbo hoses, etc. makes no difference in engine speed. Did find one small broken vacuum tube going to throttle body, but fixing it made zero difference in engine speed.

When I get all the stuff surrounding the throttle body and the throttle body itself removed, then I can finally check the function of the Engine Coolant Temperature sensor, which may be the most important input to the brain to control fuel mixture. Then can also check status of oil seperator and flame trap and hoses to them.

Keith

|

|

|

|

|

Hi,

An overfilled transmission will affect the flow rate of fluid returning to the sump and there cause a quantity of volume to circulate.

The fluid level is an important consideration from high or too low.

It why it gets checked after it is up to operating temperature as the coefficients of expansion of materials, fluids or metals, make or break getting a prototype machine to work well enough to get into production.

Trust me I know a little bit about Research and Developing products as it takes a lot of homework up in engineering. From drafting and machining it becomes a hand in hand collaboration between departments.

Having a 3,000 rpm is not considered an idle speed.

An engine that’s Not under a load is approaching it maximum torque level and the transmission is having to displace that input energy through a bypass path that it shouldn’t for any long lengths of time.

With reduced flow comes a pressure, where as, moving internals absorbs that energy.

You may be actually overheating the fluid because you are not idling low enough even in Neutral or Park.

Yes I would expect still a fluid level problem arising.

Get the idling down.

Hoe were you able to drive or stop the car with that idle speed?

You failed to mention that tidbit.

Please Tell me, It must not do it all the time?

With todays cars you would have so many codes, buzzers or lights going off, the car might take a squat with you on the side of the road. (:-)

Phil

|

|

|

|

|

Let me respond to most of the points from Phil and Dave.

Easy to stop the car at high idle speed, as when in drive, rpm is cut in half, simply use brakes and turn off the ignition. Easy enough to stop just using brakes.

Think this turbo 940 car is really worth fixing, about 150K miles, bought from previous owner who did not check any of the throttle body clearances, linkage, etc., or maintain the transmission. I am working sequentially through your list. Initally it was not even driveable with a bad misfire and transmission not driving in any gear, had transmission slippage. After transmission flush, full synthetic fluid and change of a quite dirty blocked filter, transmission was working well in all forward gears AND reverse.

Lots to fix and check impacting idle speed. OBD I is showing diagnostic codes for failed O2 sensor and wiring. Awaiting parts for that. Meanwhile will work through all the throttle body adjustments and cables, oil separator, flame trap, idle control valve, hoses... Also will make a smoke machine to look for vacuum leaks for unmetered air.

ABOUT IDLE SPEED: it starts out at about 1200 rpm the first three minutes after starting the engine, then gradually climbs to 3000 after driving about 8 miles.

Just checked trans fluid level, engine cold after sitting overnight. Idles at 1200 RPM first 3 minutes, so at 3 Min and 1200 RPM, trans level read at a hair BELOW minimum. Added 1/2 quart of fluid, which then showed between max and min marks. Although idle speed still too fast, as well as it shifts in all forward gears, I'm thinking either SOMETHING IS STUCK IN THE VALVE BODY PREVENTING CORRECT FLUID FLOW AND PRESSURE FOR REVERSE, or a SOLENOID NEEDED FOR REVERSE IS NOT WORKING. With fluid level at least close to correct, there is no change in reverse function. Engine rpm is actually 10% higher in reverse than in park or neutral. Now anticipating pulling pan, checking for anymore crap in pan and filter, and (ugh) pulling valve body, which is a royal pain....

|

|

|

|

|

When I've heard of idle climbing like that as the engine warms up, it was the ECT. That could be your entire problem. As it warms up, if the ECT goes to an open condition then the engine races, exactly as for you. A failed ECT starting out at an incorrect value thinking it's operating in sub-freezing conditions would set the base idle around 1,200-1,300 rpm and it would go up from there, again as you describe.

I've always wondered when forcing limp home mode (by disconnecting the AMM), just how many sensors are ignored. Naturally, it ignores the missing AMM signal. All I can find in the service manuals is that it defaults to a rich fuel mix map, meaning an extended injector duration. My understanding from elsewhere (and as I recall from my own driving experience in limp home mode) is that rpm is governed, or perhaps the fuel map is so crude that a rich fuel mix at lower rpm becomes a lean mix at higher rpm, making the hesitation I witness being from fuel starvation.

What I'm wondering is if the ECT is also ignored (possibly even the O2 sensor). The engine could certainly start, idle and operate half-decently not knowing the block temp. With that thought in mind, if you force your engine into limp home mode (disconnecting the AMM before starting) and as it warms up the idle does not start to race again then that would be proof that the ECT sensor is ignored and that your ECT was faulty. Maybe worth giving that a try to see if it confirms my theory.

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

|

|

|

Dave, good tip, will try disconnecting air mass meter to see what happens to RPM as it warms up. May also pull the temperature sensor, put it in a water bath on the stove, and measure resistance change as it warms up.

Think I am hearing, but cannot locate, a vacuum leak in vicinity of oil separator. That area is kind of squirrely, hard to reach without pulling off air intakes and stuff around throttle body. Since its raining and too cold, will use the time to build my smoke machine to pinpoint any vacuum leaks around the intake components. Also still waiting for replacement O2 sensor to arrive...

Once it is all sorted out, this turbo should be fun to drive. Even with incorrect low boost to the turbo, it wants to run and accelerates nicely. Will be a real sleeper at the stoplights!

|

|

|

|

|

UPDATE ON IDLE SPEED CHECK WITH AIR MASS METER DISCONNECTED /CONNECTED.

Engine cold, AMM DISCONNECTED, idles about 850 RPM after 3 minutes. At 6 minutes, ides at 1200 RPM. At 10 minutes, idles at 1300 RPM. Then, reconnecting AMM, idle jumps to 1500 RPM.

What I conclude: May have faulty temperature sensor, but likely more going on, because diagnostic codes say O2 sensor not working, and I really suspect vacuum leaks.

Can further test temperature sensor by heating it in water bath on stove, and measuring resistance change over time and temperature rise.

Pulling throttle body to clean and reset throttle plate and throttle position sensor also opens up access to the oil seperator, flame trap, and all those hidden hoses to check for vacuum leaks, etc.

Plan is to work through it methodically. Thanks for the link to previous post on throttle body adjustment!

Keith

|

|

|

|

|

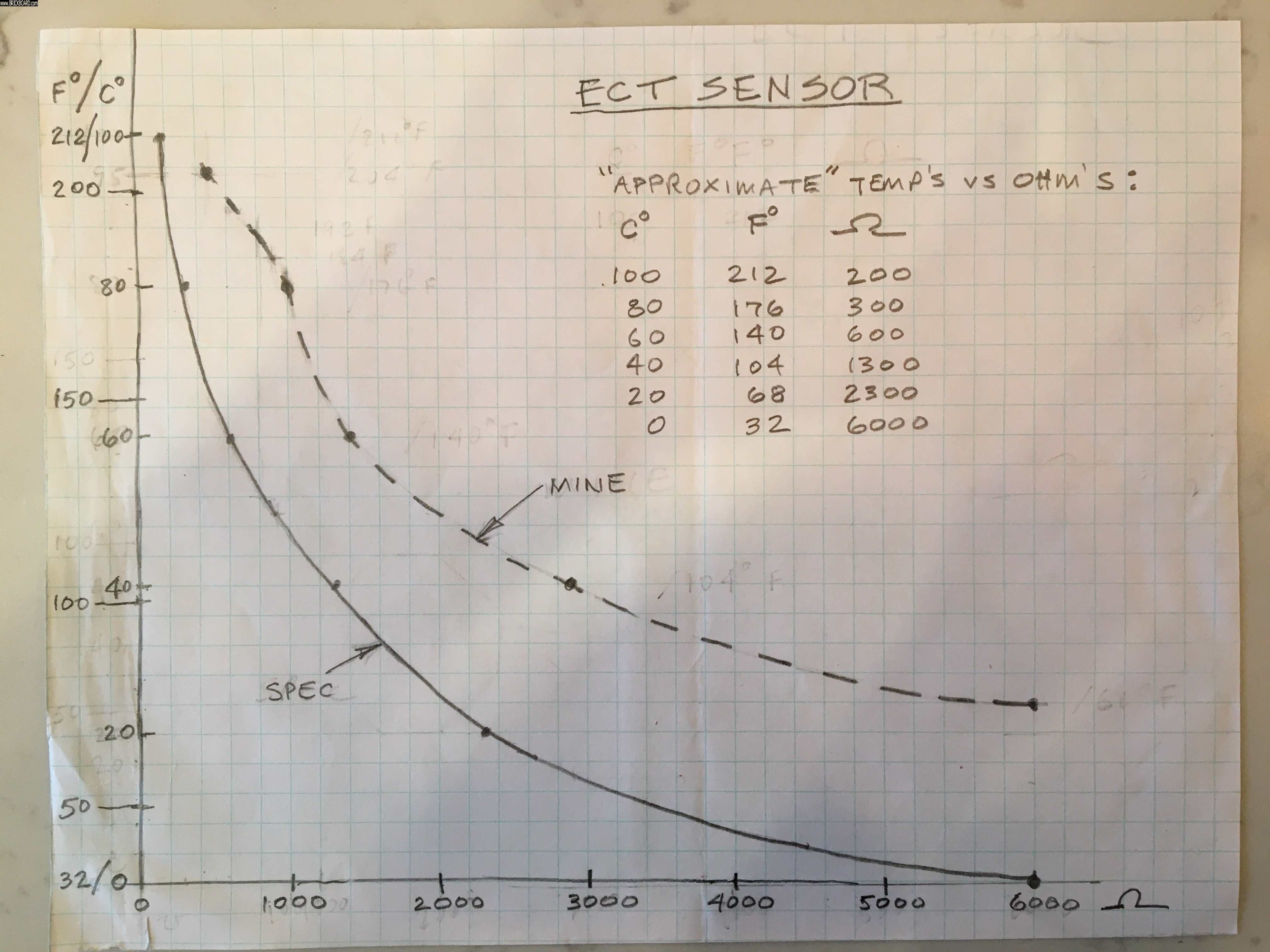

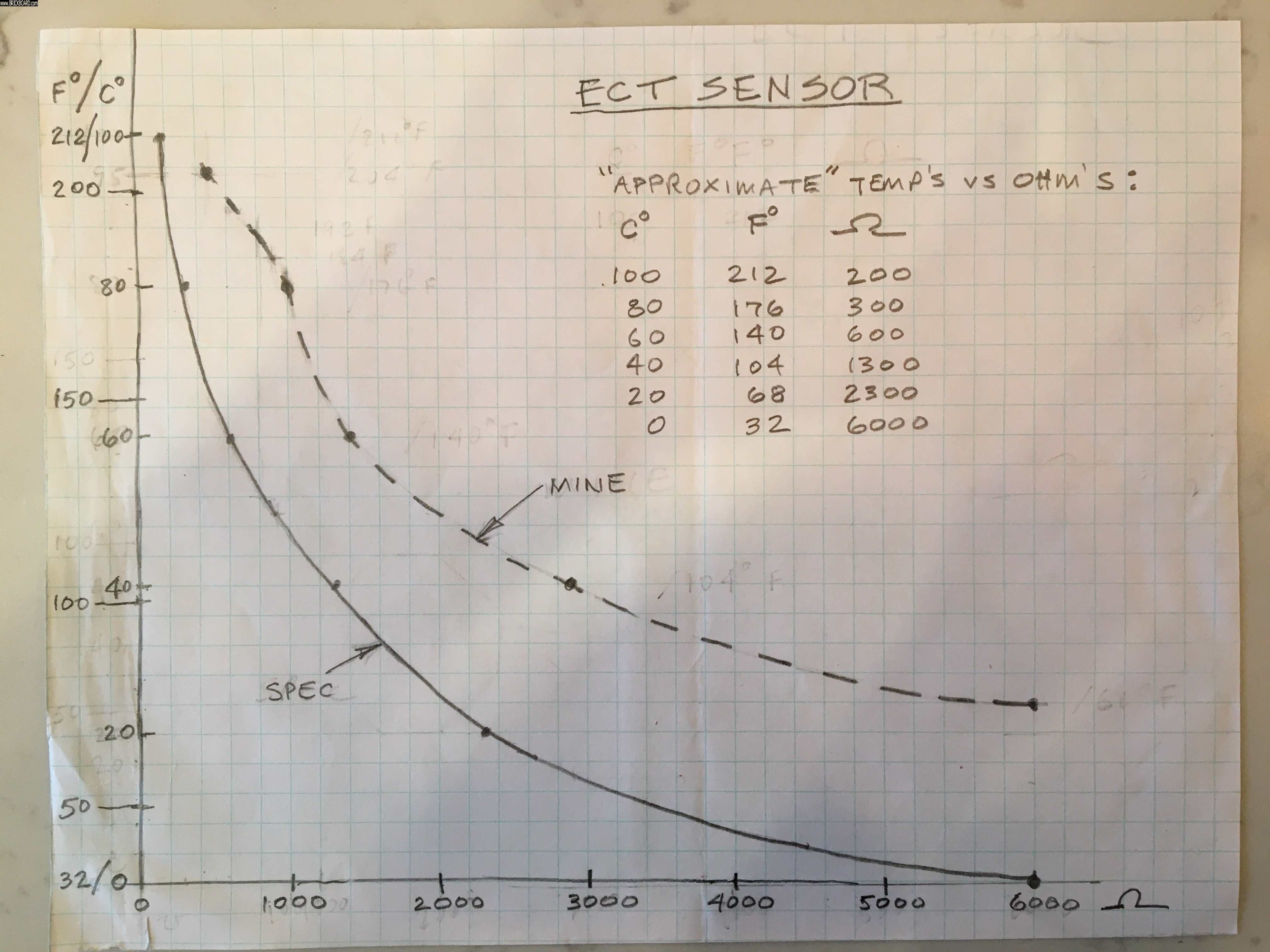

If you are checking the CTS temp vs resistance values, here is a curve I used years ago to check mine. The solid line is spec. (The dashed line is what my sensor was reading.)

|

|

|

|

|

Really intersting data, Chris. I've got 4 940s, two turbo, two asperated, 1994s and a 1995. Lots of coolant temp sensors out there for sale, may just swap for another I have after testing. If I buy one, I'm inclined to go with Bosch, which was likely OEM part.

|

|

|

|

|

I agree, likely multiple problems going on. If you go through it methodically, exactly as you plan, you'll hopefully soon have it figured out and without having to throw too many unnecessary parts at it. It takes experience to find the fine lines between replacing a part for the heck of it, doing some initial diagnosis and testing to find out what doesn't need replacing, making sure adjustments are correct before replacing something, and doing full testing to confirm exactly which component is responsible. It's made all the worse when there are multiple problems going on. There are circumstances where each of those approaches is appropriate. After all these years keeping my Volvos going, using experience, a collection of reference materials and following various Volvo forums, it's a very rare day I unnecessarily replace an ok part. Having two nearly the same 940s, I do have the advantage of often being able to swap in a known good part to confirm a diagnosis.

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

|

|

|

Dave, I've got several other 940s I can pull parts from if it comes to that, just don't like to canibalize if avoidable, because then the other vehicle is incomplete. Also too much work to go after a ECT sensor on another car, as Volvo managed to mount it in a place rather inaccessible. If Coolant Temp Sensor tests bad, will probably just buy a Bosch replacement, which is likely what was OEM part. All this takes is method, time and money!

|

|

|

|

|

Having a late model 940 turbo myself, I agree. It will be a fun car to drive, leastwise by Volvo RWD standards. The chrome Turbo badge was dropped from the back end in '95 and likely in '94, so these models indeed came to be known as 'sleepers' -a clunky old Volvo with a presumed 118 hp, getting away from a stop light along with the best of them (apart from peeling rubber, perhaps).

My 740 16-valve, with similar hp to the turbo, was also a fun drive, except more on the highway, only needing to gently hit the pedal to go up hill or pass. Peak torque is at higher rpm than the turbo. The 16-valves need to be allowed to start breathing before getting the best out of those engines. As I've said before, if I'd bought a B234F 16-valve 740 wagon instead of a sedan way back in 1989 when they first came out, I'd likely still have it, possibly with its original head if I was as good an owner as I thought I was. Broken T-belts and balance shaft belts are a near fatality for those 16-valve heads, especially those with the original manual belt tensioner (same design as the other red blocks use). The later hydraulically loaded auto-tensioner was an improvement, but if it slowly leaked down it was again game over. It's been a fair while since a B234F owner posted an issue here on the brickboard, reflecting how many are likely still on the road. I still see the occasional one on the road, mostly beaters, somebody picking up a dead car for dirt cheap and sourcing a good head or replacing a bunch of bent valves, but not caring about the rest of the car.

As for a hissing noise down by the oil separator, you may well have an EGR valve down there and in theory it could be the source of a restricted air noise, although I've never noticed it. Wouldn't hurt to pull the throttle body for a better inspection under there, also giving you the opportunity to give the TB a thorough cleaning and adjustment on the bench, including the TPS. The adjustment specs provided by Haynes are only adequate and are based on the Volvo quick checks, not the factory Volvo adjustment procedure as fully documented in a Volvo TSB for the LH 2.4 engines. You can go looking for the Volvo factory adjustment procedure in some of my ancient posts here, such as this one in the 240 forum

https://brickboard.com/RWD/volvo/1681369/220/240/260/280/throttle_body_adjustment.html

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

|

|

|

Not sure if you have a manual that spells out how to adjust the throttle plate and throttle position switch, but below is the wording from the Haynes manual. Of course you want to start with a clean throttle body and a clean idle air valve. Adjust the throttle plate stop, THEN adjust the throttle switch, not in the reverse order. Note the manual suggests that you perform the resistance/continuity measurements at the computer but I could never understand why you can't take those measurements right at the switch connection unless you are trying to detect any possible bad wiring between the switch and the computer:

Quoting the Chilton Manual:

Base Throttle Plate Stop Adjustment

Loosen the throttle locknut.

2. Loosen the adjustment screw until the throttle is com-

pletely closed.

3. Tighten the adjustment screw until it just touches the

linkarm, then turn a half à turn further.

4. Tighten the locknut without changing the adjusting screw

position.

5. It may be necessary to loosen the throttle switch before

setting the throttle.

Throttle Position Switch Adjustment

1. Open the throttle slightly and listen to the switch. There

should be a click when the shutter opens, if the adjustment is

correct.

2. Loosen the throttle switch mounting bolts.

3. Turn the switch slightly clockwise.

4. Turn the switch counter-clockwise until the switch clicks,

then tighten the mounting bolts.

5. Recheck the setting.

TESTING

1. Tum ignition switch to the OFF position.

2. Check the throttle switch by connecting an ohmmeter

between ground and pin 2 on the control unit connector. ohm-

meter should read O ohms (switch closed).-

3. Depress gas pedal slightly, resistance should increase to

2000-3000 ohms (switch opens).

Connect an ohmmeter between ground and pin 3 connection on the

control unit connector. Ohmmeter should read

infinity. (full load switch open).

5. Depress gas pedal all the way. Ohmmeter should read O

ohms.

6. If specifications are not as specified, check at throttle

switch to see if fault is in throttle switch or its leads. Check

ground connections at intake manifold.

|

|

|

|

|

Chris,

Thanks for the rundown on setting up the throttle body. I'll do the complete procedure once I do a lot of vacuum leak testing and get a fresh throttle body gasket. Everytime I've done the throttle plate clearance check and cleaned the throttle body on other Volvos and BMWs, it has made a noticable diffenence in drivability. Need a dry sunny day to pull it all apart. Will post the results.

|

|

|

|

|

It sounds as though something inside the O/D unit may have busted. That would explain the 1000 RPM increase at highway speed. They’re not really built to withstand crazy amounts of torque being applied to them, especially in reverse.

Is there any difference in highway RPM whether the O/D lockout button is activated vs not activated.

|

|

|

|

|

Overdrive switch and solenoid respond on and off immediately. At 65 mph in overdrive rpm is about 4000, which seems high. Pushing overdrive button to disengage, rpm jumps to about 5000 rpm. This may be a problem with the lockup solenoid for the AW71L torque converter. Think this is not at all related to reverse gear function.

|

|

|

|

|