|

Hi CB, Onkel Udo II, Tony, darkdelta, Art Benstein, Nel621, Volvodad, laharview and John Sargent

Thank you to all and you guys rock!!!

It all began three months after I got my flying brick, I saw a tiny rust spot sprung out like a crabgrass and it grew and got bigger every week. There were more spots appeared and they looked like a baklava. That's how I came up with the name "swedish baklava".

water leaking area...

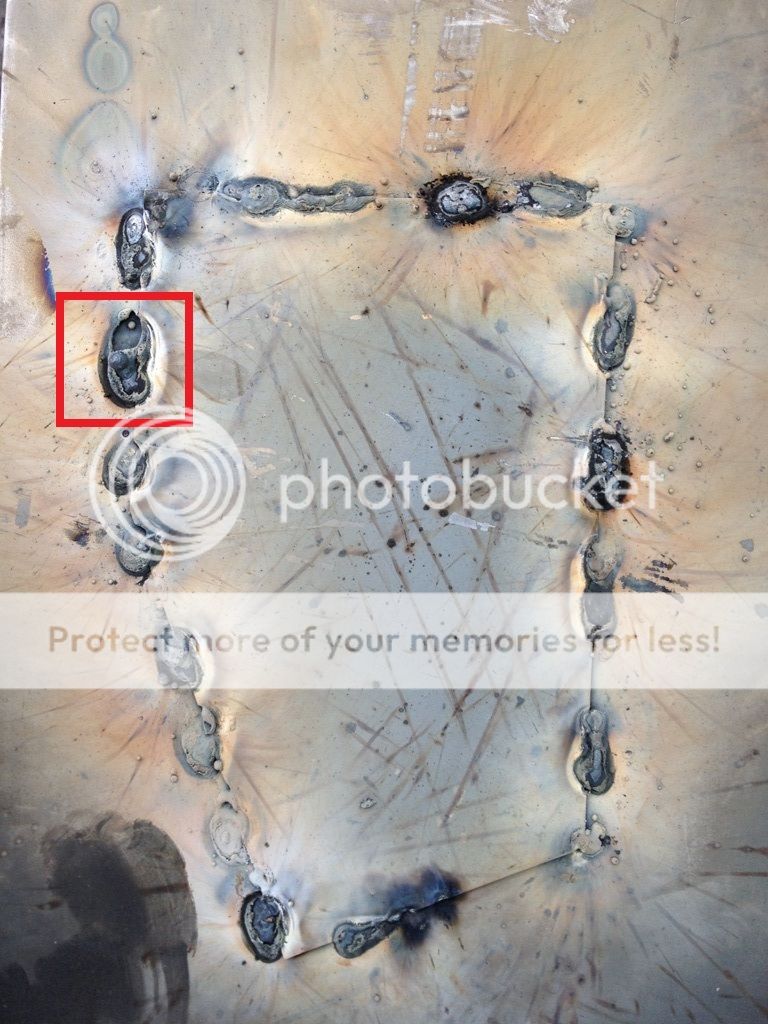

Testing at a metal shop... Welding upside down with one hand. I had to hold my helmet with the other hand... Got cocky, almost dripped! Checked my 50ft extension cord now and then... It was very cool and my welder never got hot. I felt ready.

Disconnect the battery and I was ready to weld. That simple.... I went down to several muffler shops and spoke with welders as Tony recommended. They all said, "JUST WELD!" No gypsum board partition needed. lol.... Over the years, I was so spoiled and blinded by the google search engine. Tony, I would like to give you two thumbs up but it allowed me to give you only one thumb up. Thank you for waking me up!!!!!!!!!!

POR15 treatment + grinding

Applied weld thru primer

50ft extension made it. Swapped to a 20amp receiver, checked for 12 gauge wire. Thanks Volvodad!!!

Check 1234...

Made a hole. Thin rusted metal area?? Maybe I hold it too long... I thought I melted the wiring above.

Taking a break... That hole....

Mixed the putty at 50 degree, applied at 40 degree and left for 7 days. It's not curing at all. Heating didn't help... I might have to redo it next summer.

Can't wait any longer. Applied POR15 and ready to hit the road again. Reconnected the battery, started the car and it ran. I didn't fried or melted any wires. :)

Things I should or shouldn't have done...

1. Stuffed rust area with wheel bearing grease. Oh, boy... I was desperate.

2. Wrap the wiring with anti flammable fabric before I started to weld. I could weld more and longer beads.

3. Test a small piece of POR15 putty before I went all out since the temp was very cold.

http://www.brickboard.com/RWD/volvo/1544490/220/240/260/280/re_87_245_auto_welding_floor_panoutside_set.html

http://www.brickboard.com/RWD/volvo/1548666/220/240/260/280/re_87_245_auto_50_ft_extension_cord_20amp_83_question.html

Thank you all for your support and guidance!!! Everything went well as you have expected! Happy New Year 2013!

|