|

Volvo, like most automakers, climbed onto the 'plastic headlight' bandwagon in the late 1970's. The actual material used is 'Lexan,' not Plexiglass.

The difference between the two materials is that Plexiglass is more brittle and also more UVA and UVB (sunlight damage) resistant. Lexan was the material of choice for the headlights because it's less prone to chipping or cracking when struck by stones, large bugs, etc.

What we usually end up with is headlights that turn milky and amost unusable, while sidelights (being Plexiglass) are still clear and pretty.

There are several ways to temporarily cure the milkiness: you can shell out $300+ for new headlight housings, prowl the wrecking yards in hope of finding headlights less damaged than yours, or use either mechanical or chemical polishing to remove the top 'crazed' layer of Lexan.

I have been told by several people that a careful application of brake fluid, poured onto a cloth then used on the headlights, will eat away the damaged surface layer and leave only clear Lexan behind. My opinion is that brake fluid has one use: to transfer pedal pressure to all four brakes to stop your car. It's highly toxic and caustic; it will immediately eat away any automotive paint it comes into contact with. If you try this method, try it out on a headlight that's been removed from the car. Frankly, I wouldn't EVER try it.

My preferred method of repair is to purchase a few cheap materials and either using a drill motor or by hand, polish away the damaged layers. By using successive finer and finer abrasives, you can quite quickly cut through the heavy damage and then move on to a finer abrasive to give the headlight a crystal shine - much like new - at very little expense and effort.

I use a 3" or 4" linen cloth buffing wheel that I can chuck into a drill motor. I've been buying all my materials at Harbor Freight (www.harborfreight.com) but I'm sure any hardware store or home center will also carry the stuff you'll need.

At Harbor Freight the buffing wheels cost $2-$3 each, and last nearly forever. You can also disassemble the metal shaft assembly and toss the cloth part into the washing machine.

In addition, I use stick-type polishing compounds. These come in a tube and are somewhat like a crayon in a large size. There are several different grades, or grits available, and they are each a different color. The outside of the tube will explain what each grit is intended to do, so I use a Tripoli (blue-fairly coarse) followed by a Rouge (red-very fine.) You may decide to just buy a stick of every type available so you can do many more polishing jobs than just on your plastic headlights. Compound sticks should be in the $2 range, with some a little more, depending on the cost of the materials to make them. I'm still using sticks that I bought three years ago, so they will last through many jobs.

Start your buffing wheel spinning and press the compound stick into it and you'll transfer enough abrasive to start polishing. As the wheel starts to lose its effectiveness, add more compound.

One other method which many people choose simply because they already have the materials on hand, is to use a paste-type rubbing or polishing compound and a clean rag, with a liberal dose of elbow grease.

I've heard of people using toothpaste - great for small items like jewelry, but pretty messy and expensive for a bigger job!

More commonly, I'd say go to Wally World and get a tub of Turtle Wax Rubbing compound, a tub of Polishing compound (just like the abrasive sticks above, but these are paste and are available everywhere.)

You can rub a little paste abrasive into your buffing wheel, or place a little glob on a cloth, and start polishing.

Using whatever method, I keep rubbing until the headlight is pretty clear, but not perfect. Any coarse abrasive, whether stick Tripoli or rubbing compound, will never get the tiny scratches out of the plastic. Just like sanding wood, you'll want to change over to a very fine 'sandpaper' to get the brilliant, clear finish.

If I'm using a buffing wheel setup, I'll change wheels so as to not be grinding the remains of the coarse Tripoli back into the plastic. A fresh wheel with Rouge on it works much better.

Once I'm satisfied I've done the best job I can (maybe 10 minutes using a buffing wheel) I'll carefully clean the headlight and put on a coat of UV inhibitor, like ArmorAll or Aerospace 303.

As with any kind of automotive maintneance, this is something you'll want to do periodically to keep your headlights sparkling. After the initial work to get the heavy damage removed, its pretty easy to add a few minutes to your car wash/wax routine to touch up your headlights.

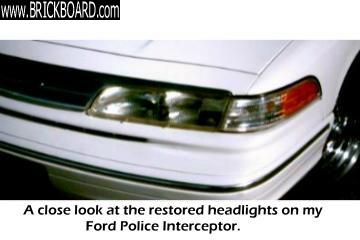

The only problem I've discovered is that I've become somewhat addicted to polishing things...I even polished out the last 2 feet of the dual stainless steel exhaust on my Ford Police Interceptor. Everyone at shows wanted to know where I got the amazing 'chromed' exhaust!

Respectfully submitted for your enjoyement - Steve

|