|

|

Hello All:

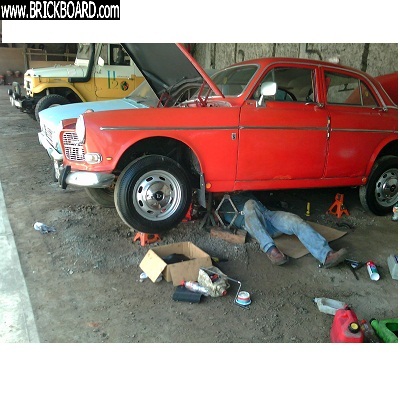

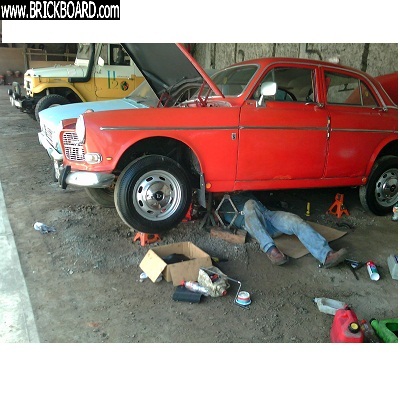

1967 Volvo 122S Wagon. As some of you might recall, last week I found cylinder #3 had 35PSI compression. I finally procured a garage and did a leak down test last night - with #3 at top dead center, both valves closed, the air is leaking out of the exhaust pipe. I also observed that the rocker for that valve is noticably higher than the other rockers, indicating a retreat of the valve into the head, no? Tonight I pull the head.

I got some great advice from SteveW about doing that last week. Here is the excerpt:

"You need to remove the valve cover, and pull the rocker arm assembly to access the head bolts. Disconnect the upper radiator hose, heater hose from the back of the head, temperature sending unit, choke cables, fuel line, ignition cables, throttle linkage and the exhaust manifold flange to the exhaust pipe. Once the headbolts are removed, the entire head with intake and exhaust manifolds can be removed."

A few questions:

-I have never removed the rocker assembly before. It seems pretty straightforward, just removing the bolts. Correct? I assume I need to stagger the loosening since the various rockers will be pushing against the valve stems. I won't need a spring compressor to get this back together, will I?

-It appears that there are two hoses coming from the back of the block. Excuse my ignorance, but does this filter the hot coolant from the engine into the heater core in the dashboard and back out? If so, I assume I have to remove both hoses, correct? Do I need to drain the block of coolant before I do all of this?

-The temperature sending unit is the wire coming from the back of the head, I assume. Any special care tips?

-Choke cables, fuel line and ignition wires are self-explanatory, but the throttle linkage is a bit perplexing. I have looked at it but cannot figure out the most efficient way of disconnecting it from the carburetors.

-If by "exhaust manifold flange" SteveW meant the three-bolt triangular flange, I might have a problem. They look like they will not be coming apart any time soon, although I will shoot it with some PB Blaster first. Barring that, what do I need to do to get the exhaust manifold off? Are there other options?

I know, another long post from Pooch, but I really am new to all of this and I am doing it solo (which is probably why the valve got burnt in the first place). Many thanks for the help.

Cheers,

Jeff Pucillo

|

|

-

|

|

Good to hear that you're not intimidated by this repair. Sure sounds like you will probably get by with a valve job. I doubt anything you did contributed to the demise of the valve unless it was adjusted wrong. Exhaust valves normally get beat up more than intakes. Might be a little premature, but if this car lived life in the city (low overall mileage but many run cycles) I wouldn't be surprised about valve wear.

Along with what John Mc said

Rocker Arm - I usually back the valve adjusting screws out to relieve some of the pressure on the arm before removing the arm bolts.

Heater pipes - Yes remove the upper hose. I don't think you will have to remove the lower one. Definately drain both block and radiator, otherwise you will spill coolant into the cylinders when removing the head. You will probably spill some, but this will reduce the amount...dry it well after removing the head.

Temp sender - Keep a close eye on it when removing. Don't let the capilary tube twist with the retaining nut. If it does, soak it again with PB and be patient. All bets are off then!

Linkages - I pull the linkage at the carbs and then remove the linkage from the firewall to the intake to get it out of the way. Comes apart real easy. I pull the carbs also at this time.

Manifold to downpipe connection - Good luck. Soak it and cross your fingers. Be sure your wrench fits tight and you can get a straight pull on it. Don't use an open end wrench...box or socket only. You don't want to round off those nuts obviously. It may be possible, but a pain in the neck to leave it connected and remove all the manifold to head nuts and pull the manifold out of the way. Sometimes the studs don't give you enough room to pull away though.

This project is straightforward and you've got the right attitude. Go for it!

You have a torque wrench for re-assemby right?

--

'60 544, '68 220S, '70 145S, '72 144E, '86 745T

|

|

-

|

|

Rocker assembly - A valve or two among the 8 is usually down at least partway probably all the time. You can just unbolt the rocker shaft bolts though, don't worry too much about bending or skewing anything, just unbolt it. When retightening I tend to do each bolt a little bit in sequence until all are tight. No spring compressors needed for this, just to remove the springs and valves themselves.

One of the hoses on the back of the engine hooks to an elbow pipe fitting in the back of the hed, the other to a pipe reaching around to the water pump on the front. That pipe usually has (at least when it rolled out of the factory) a little metal tab to support it at the rear bolted under the rear-most manifold nut.

The temp sender (assuming it is an original mechanical sender) is very fragile. I'd soak it with PBLaster liberally to minimize the chances that it will stick to the retaining nut and try to twist as it is unscrewed.

The little ball joints on the throttle linkage are stuck together by little metal pins/clips that clip around the shaft. To remove them rotate them out from the shaft, then pull straight down away from the balljoint. Hard to explain, simple once you notice that the little metal clip thing is there.

From my experience, it's usually better to just unbolt the manifolds from the head. Get the bulky stuff off the head before unbolting it from the block. Plus, I've usually found that manifold to downpipe connection to be a b%$(*& to get apart, the manifold to head nuts are usually much more cooperative. Once the manifolds are unbolted (some of the underside nuts are hidden well, but you can usually get to them easily once you know they are there) the carbs can just be set aside, and the exhaust manifold can be let attached to the exhaust system and just pulled aside.

Drain the coolant first, from both the radiator and the block.

--

I'm JohnMc, and I approved this message.

|

|

-

|

|

>the exhaust manifold can be let attached to the exhaust system

>and just pulled aside.

You can use a bit of rope (attached to the point of support carb linkage on the manifold and to the trunk hinge) to separate the manifold from the original position, making space to work (http://www.geocities.com/yogui7/3/pages/PIC0014.htm, the carb and related linkage before was taken out before it).

--

Joaquin / Rojo 121 / Lima, Peru

|

|

-

|

|

Hello All:

Many thanks for the remarks.

Yes, I have a torque wrench.

Once I get the head off and determine the problem, how do I do a valve job? I assume the head needs to be handled by a reputable machine shop. Does anyone know one in Westchester County, NY? Any estimate on the cost?

Cheers,

Jeff Pucillo

|

|

-

posted by

someone claiming to be cardog

on

Tue Dec 20 17:33 CST 2005 [ RELATED]

|

|

Hi Jeff,

In Bedford on Railroad ave. there is a place I believe called Viking Motors or Viking something. I have never been there or done any business there. I have only driven past them, so I can't vouch for anything personally, but I do know they do a lot of work on older Volvos. I don't know if they have a machine shop, but may be able to point you in the right dirrection.

Chris

|

|

-

|

|

Jeff,

How do you do a valve job? Easy, you don't! Definately need a professional to do it right.

Don't know any in Westchester but I had a B20 head done about two years ago from a shop in Waterbury CT.

The job was $380 and included resurfacing the head, 4 new exhaust valves, 4 new valve seats, head gasket set, and removing a stud that was broken off inside the head. Breakdown was $125 for parts and $235 for labor.

He included the gasket set ($65) because he needed the valve seals.

--

'60 544, '68 220S, '70 145S, '72 144E, '86 745T

|

|

-

posted by

someone claiming to be RVVR

on

Wed Dec 21 02:45 CST 2005 [ RELATED]

|

|

JEFF,,forget Viking motors,, they will roll you! and i have seen some of there sloppy work..I have used Precision Machine in Valhalla ny....talk to Jeff @914-949-2093..he has done several heads for me with no problems!

|

|

-

|

|

You should almost certainly spring for some hardened valve seats while someone is working on it. It's one of those things that is silly to take the engine apart for merely as a precaution, but since the head is there anyhow...

--

I'm JohnMc, and I approved this message.

|

|

-

|

|

Hello All:

Great advice, everyone. I managed to get the head pulled last night. I am happy to say that the head and manifold gaskets looked great (I know I should replace the head gasket, but do I need to replace the manifold gasket?) the cylinder walls look fantastic, and the pistons themselves look solid, though blackened. All ports and everything else look solid.

A few months ago someone posted here to remove the rocker assembly and run a straightedge along the top of the valve stems to determine if there was a receding valve problem. I did that last night and Virginia failed miserably. So tell me, what should the valves look like? The intake valves are black with a rough surface, the exhaust valves are clearly burnt and white, particularly for cylinder #3 and less so but noticeably for cylinder #1. #s 3 and 1 are also clearly receding into the head.

Perhaps someone can give me a few tips:

1) Exhaust manifold nuts - I had a heck of a time removing the second nut from the front on the lower "tier". This is located almost directly below the intake for cylinder 2, and behind the alternator. It took me nearly two hours of fotzing to get it off - getting it on will cause me to lose sleep. Any hints?

2) When I reassemble all of this, what is the proper way to treat the surfaces? Should I use steel wool to get the smudge off the mating surfaces?

Once again, thanks to all of you for the help. I had a very satisfying experience doing this, one of the best feelings of accomplishment ever. I cannot imagine how I will feel if I actually get it put back together properly.

Cheers,

Jeff Pucillo

|

|

-

posted by

someone claiming to be shayne

on

Wed Dec 21 08:03 CST 2005 [ RELATED]

|

|

1) Exhaust manifold nuts - I had a heck of a time removing the second nut from the front on the lower "tier". This is located almost directly below the intake for cylinder 2, and behind the alternator. It took me nearly two hours of fotzing to get it off - getting it on will cause me to lose sleep. Any hints?

Phil S taught me years ago, with the carbs and heat-shield taken off the intake manifold, those nuts are a piece of cake with a socket and long extention. And it's really not that much more to remove carbs from manny.

I would replace the manifold gasket, I don't consider it re-useable. If you are careful with the carb-to-manifold gakets, they shoud be okay.

Shayne.

|

|

-

|

|

Jeff,

Sounds like the bottom end is going to be ok, but definately have valve issues.

Can't really tell the condition of the sealing surface of the valves until they are out. Receeded and or out of round is not good that's for sure. Color, I think is tough to say.

Manifold nuts - Consider changing the studs and nuts with new ones. For the cost, there's a good chance that's one less headache.

Surfaces - Clean, clean, clean. I usually just scrape with a razor. When doing the top of the block, I use a razor and have the hose of a running shop vacuum right next to the blade to suck up anything. You should avoid having the scrapings fall into the cylinders. Me, I don't use any gasket sealer. If the surfaces mate properly you shouldn't need it.

One other thing, while you have the straightedge out, put it across the manifold. You may find that the surface has warped some over the years and will have to be trued. Now would be a good time to have it re-surfaced as well. Did you get the exhaust flange nuts off ok? May want to consider renewing those as well.

--

'60 544, '68 220S, '70 145S, '72 144E, '86 745T

|

|

|

|

|