|

|

|

The other day my 1989 Volvo 240 auto trans left me stranded. It suddenly died while driving. It would crank but not turn over. Looking through the oil filler cap I could see that the camshaft was not moving, tow truck time. I just recently did an oil change with wal-mart brand oil and oil filter (Yeah I know). For the past couple of days it has been a bone chilling 40 degrees here, so I just now got to work on it today.

Upon inspection the timing belt was shredded and torn in half. The cam and sprocket would not budge until I took a wrench to it. Even then it was very stiff.

So I am thinking new camshaft, camshaft bearings, timing belt, tensioner, water pump, various seals and I might as well replace the head gasket while I am at it. I guess I should have read my Bentley a little better. There are no cam bearings. The first bearing/cap (behind cam sprocket) is a bit scoured and the rest show a little bit of wear. So what do I need to do to prepare these caps for a new camshaft? Scotch Brite, extra fine steel wool, or some super fine sand paper? Do I need to have the machine shop line hone the head? I'm planning for a valve job anyway but line honing is expensive. Should I just go to the salvage yard and get another head?

Another question how fast do I need to spin the intermediate shaft to get oil to the top of the head? On Chevy and Mopar V8 I can just spin the crank by hand and get oil.

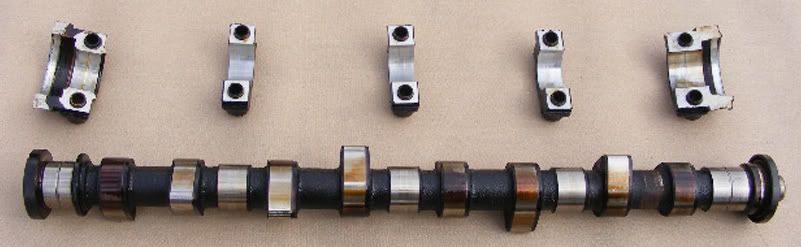

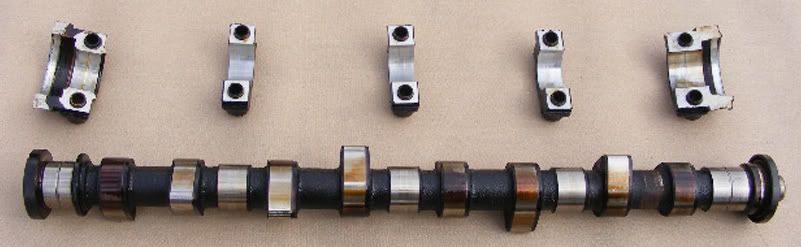

Some pictures

camshaft, cam bearing caps, torn timing belt

camshaft and caps

#1 cam bearing cap (behind cam sprocket) see the shiney spots

cylinder head cam saddles (look kinda burnt)

cylinder head cam saddles (look likda burnt)

|

|

|

|

|

I've seen this problem a number of times. Been able to set it right without taking off the head. Wire brushed the cam journals (even with aluminum embedded in the journal the cams were fine after cleaning), hand sanded the cylinder head journals and caps, remove the oil galley plugs at each end of the head, used spray solvent and piece of wire down each journal oil passage, remove head bolt with oil passage-as another poster mentioned, used compressed air to blow it all out. Remember to put the threaded plugs back in the galley ends. Lube everything thoroughly on assembly.

|

|

|

|

|

If you could turn the cam with a wrench I give it a passing grade.

You shredded a timing belt. How many miles were on the belt???

Since you already have it out you could lightly polish the cam journals with a little 400 silicon carbide paper and oil. There is nothing wrong with that cam or the bearings. They are good for another 250,000 miles, assuming you start using Mann filters and a better grade of oil (grin).

It needs a timing belt.

Randy

|

|

|

|

|

While the belt's off, turn the intermediate shaft in its normal direction and see if it's feeding oil to the top end. You'll probably have to spin it with a drill motor or the like. If you get good oil flow, clean things up a bit and put it back together.

If no oil, remove the second head bolt back from the front on the exhaust side (I THINK that's the one that doubles as the oil passage to the top end) and see if you can clean it out some how.

I had a cam freeze up once due to poor oil circulation, and like everyone else is saying, it looked quite a bit worse than your's.

|

|

|

|

|

I can tell you what we did to them back in the day, we had a big/long reamer that we ran through it. Bolt all of the cam caps down, run the reamer through it, clean up the mess, and put it all back together.

Mark

|

|

|

|

Other folks with more experience with engine internals will have to chime in but -

The pics don't look bad to me.

I've had a couple of #5 end caps off, to replace the rear cam plug. Looked just like your photos. I'd say it's varnish. I don't think it's anything that would cause the cam to seize.

I cleaned the caps that I removed with a rag and carb cleaner and brake cleaner - what I had handy. I figured better to rub a bit than to scuff the metal. Worked out well.

Maybe it had an interference cam and a valve got jammed?? Perish the thought but with what you've disassembled you can tell.

Take a look at the back end of the cam itself for the cam designation. Standard cam for a USA market '89 240 is M. The L, M, A, and B cams are non-interference. There are a few cams that turn it into an interference engine. The only Volvo-made interference ones I know of are the K + V cams but there are some aftermarket ones out there.

Lastly, I'm not sure why you'd pull the head. Assuming no head gasket leak or piston/valve issues I think you can do what you need from where you are.

I still don't see why the cam froze. Maybe a valve collision but where and why? Maybe clean it and reassemble and see if cam turns better? Try turn the crank too (24 mm), just to see. Reinstalling bearing caps needs gradual tightening, kinda like torquing a head. Read Bentley for sequence/specs.

I hope someone else will post on this before too long. I don't have enough experience on this.

--

Sven: '89 245 NA, 951 ECU, expanded air dam, forward belly pan reaches oem belly pan, airbox heater upgraded, E-fan, 205/65-15 at 50 psi, IPD sways, no a/c-p/s belt, E-Codes, amber front corner reflectors, aero front face, quad horns, tach, small clock.

|

|

|

|

I don't know J, That looks fine to me, I've seen way worse then that turn fine. There is a bit of wear (shine) but that should not prevent your cam from turning. I don't see any deep gouge marks, and that burnt, is just oil stain from not changing the oil. When did you replace your timing belt last? was it due? Does the belt have cracks?

You said that the cam was "Stiff" and hard to turn by hand. when you used the wrench, did it pop like it should to the next place, or did it just meander slowly? I can post a movie of me turning my "spare head" with a wrench if you have any questions on how it should turn, or how the bearings should look.

Use that redline assy lube, and you shouldn't have any problems with startup. It is a red gel that works well.

Wal-mart oil and filter are cheap, but they should suffice, as long as the oil level is proper. Also, the filter may not possess the drainback valve. Did the failure occur right after a cold start, or was the engine warm?

If you want a new head, you can get them at the pull and save for 25 bucks. Quite a deal.

|

|

|

|

|

I really need to get this job done soon as possible. So I might just skip the head gasket. It is an "M" cam so I will go ahead and replace it with an "A" cam.

" You said that the cam was "Stiff" and hard to turn by hand. when you used the wrench, did it pop like it should to the next place, or did it just meander slowly? "

You definitely could not turn the cam sprocket by hand. It did "pop" or kind of "jumped" when it moved past the lobes. I could turn it with a wrench and a firm grip.

"I can post a movie of me turning my "spare head" with a wrench if you have any questions on how it should turn, or how the bearings should look."

That would be very helpful. I would really appreciate that.

"Did the failure occur right after a cold start, or was the engine warm?"

It occurred early in the morning about 40 degrees lightly raining. I had driven for about 10 miles at about 65 to 70 mph (2000 - 2500 RPM). I did not notice any strange ticking, tapping or knocking sounds.

I am nervous about oil getting to the top of the cylinder head. What is the best way to verify that oil is reaching the top on these engines. Forgive me I am really a Mopar and Chevy man.

|

|

|

|

Right on J, I should be able to post a movie by tonight.

Since the engine had been running for a while, the possiblity of a wal-mart botching is unlikely.

There really is no way to pressurize the oil galleys without taking the t-belt off and spinning the Intermediate shaft with a power drill, or if you are really into it you could connect a line from a oil tank under pressure right to the oil light pressure port next to the oil filter.

There is another port J, on the back of the head, it has conical threads and is very likely a oil pressure port for a gauge. If you have any concerns, you might observe gauge pressure at that port.

It is possible J, that the belt was just old and broke because it was not replaced at the proper interval. If this is the case, then you should just replace the belt and put your old cam back in. If you switch cams, the valve clearences might change, and then you would have to obtian shims (another delay). If I were you, I'd obtain a pull and pickyard head, and build that one (vat & valve job). That way, when you have the time, it makes the operation simple.

|

|

|

|

http://s262.photobucket.com/albums/ii87/kylechap/?action=view¤t=121307_16431.flv

I hope this helps you out!!!

Sorry about the quality.

|

|

|

|

Right on J, I should be able to post a movie by tonight.

Since the engine had been running for a while, the possiblity of a wal-mart botching is unlikely.

There really is no way to pressurize the oil galleys without taking the t-belt off and spinning the Intermediate shaft with a power drill, or if you are really into it you could connect a line from a oil tank under pressure right to the oil light pressure port next to the oil filter.

There is another port J, on the back of the head, it has conical threads and is very likely a oil pressure port for a gauge. If you have any concerns, you might observe gauge pressure at that port.

It is possible J, that the belt was just old and broke because it was not replaced at the proper interval. If this is the case, then you should just replace the belt and put your old cam back in. If you switch cams, the valve clearences might change, and then you would have to obtian shims (another delay). If I were you, I'd obtain a pull and pickyard head, and build that one (valve job). That way, when you have the time, it makes the operation simple.

|

|

|

|

|