|

I still monitor some of these boards.

Updates have not been done, *partly* due to the info being rehosted by 1800philes, which make it harder for me to maintain or adjust (ie having to work by e-mail), but *primarily* due to not being especially required, as I will try to point out.

Mainly, though, the information in the charts I complied is intended to aid informed choice, and to correctly "sequence" or group the cams in order of resultant rev range, and I doubt there's concern that the charts have any real weakness for that purpose.

***

IMO, one of the issues Paul and Ben have is that many of their samples are either lightly used, or are "jobber" copies. Use often takes very little off, but it worth mentioning in passing. The bigger issue is the jobber copies. When offering a product, volume cam grinding companies do not usually develop a new "Master" lobe to work from, instead choosing one from their existing "library" after precision measuring the sample they aquired. For instance, I know Melling and the US import parts distributor Impact sold the same A, C & D copies that IPD sold or sell. These are close copies based off design mathematics for Chevy Small Block lobes. In the same way, Wolverine/Blue Racer (absorbed by the Crane Cam group) sold very nice R-grind copies (p/n wg1171, obsolete) based off SBC lobe designs. I believe these, or an independently manufactured equivalent, were also available from Melling. I've seen on EBay, a Crane b20 cam that was essentially a D-grind, though in their case they made no claim to that nomenclature. I am not sure where Ben's "S" cam was sourced from. Being that the cores are made solely in the US, what you get when you order, say, a D cam from KG Trimning in Sweden or from Scandcar in Holland may well be an American copy of a used D-cam supplied to a US manufacturer during the 1970's... in fact, I believe this to be so.

There is also some desire to have somewhat generous dimensions accepted, for SCCA ITB use. In no way has this influenced my stats, but it bears noting that is is possible to buy a D cam that very slightly exceeds my duration specs, which in turn exceed Ben's/Paul's by a slightly greater amount.

To try to wrap up this point and move on, what I have done is to use original Volvo data (from memory, the R-sport Catalog was a leading source), and averaged it with what I've seen people come up with more recently in the field. In some cases, I've weighted the averages more heavily toward original Volvo design data.

*******

The method and tools that Ben and Paul use - a degree wheel and magnetic dial indicator- are very accurate at the higher lifts, but 'perfect' statistical accuracy can be difficult on the .010-0.015-0.020 measurements. I would say 2 degrees plus or minus, possibly 3 depending on how late at night it is... so say 4-5 degrees, total. At that point it can be useful to review, fudge, or "smooth" your data, based on how cams are ground. There's almost always a fixed mathematics used by any one manufacturer, and the cam is simply "grown" for greater duration applications. What this means is that the change from one lift to another, should take place in a very similar number of degrees in different duration lobes (statistically, the exception being the duration approaching max lift, though it's logical that this should be so). So, I can most assuredly point out a genuine error in the chart Paul posted: the Isky cams, #61 & 71 have an "anomoly" at .050"... they are 12 degrees different through out the range, except at .050, where they are reported to be only 4 degrees different.

Bearing in mind the size of the actual part, and that flat tappet cams are generally ground with a 3" radius wheel, it's barely possibly that this could be so, and if it were, one or the other would be an unhappy lobe design, due to the deviation from the basic parabolic shape. Far more likely, the information from Isky was misconstrued or mistyped.

Another example is that the K-cam was developed to help the K-Jetronic system give good throttle response off idle. I think it extremely unlikely that they radically extended the opening ramps. They may have slightly extended them for wear reduction or tappet noise reduction. In the given numbers I see an another *highly* unlikely anomoly with the low lift durations of the C& K vs the D. I suspect that either the C/K pair, or the D sample, was from a different lobe/manufacturer, and as such is not comparable in fine detail.

*****

I am not sure what you (Paul) are referring to when you state that the "enem 18" is "wrong"...without animous, possibly only that one of the several applying statistics are off by a couple numerals?

How have you determined this?

Bearing the above discussion about lobe families, how is it you have issues with the 18 but not the 16, 17 or 19?

Janne Careborn at Enem specifically states he used .020" as advertised, so the Adv. Dur. #'s (&lift, & lobe separation) are as given by his own paperwork and website...

By using the useful lift-at-TDC figures often supplied by Euro/Swedish vendors, you can "triangulate" and have a further data point. On the cams of that group, that was a great help in approximating the @.050".

On the other hand, it is faintly possible that Janne is doing something odd like taking the lash out, as the impression I got a few years ago was that Phil S's car doesn't really quite act like his K19 is as big as the stats show, so I am willing to listen.

Janne also changed manufacturing and/or design equipment since the original OHV range was offered, so again, it is faintly possible he is now making "artist's interpretations" of his own previous product, with slightly altered stats.

*****

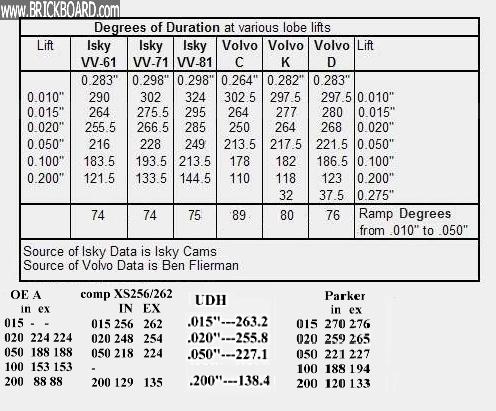

When Paul originally posted the chart above, I copied it into a photo editor, contrasted it, sectioned it, and adjusted it. I'll add the result at the bottom. I am not even sure I regard this as a fully definitive set of stats, but more my revision of something I've seen posted.

I've also added along the bottom, mostly for my own use.

The A data is, I think, from Ben from Holland as well. It seems almost suspiciously short...

The Comp is CompCams of Memphis TN. The shown pair of lobes was "state of the art" in around spring 2003. I was seeking maximum lobe size while maintaining minimum duration.

The UDH is a prototype lobe that exists only in CAD/CAM type programming. It is the result of showing my criteria to an expereinced and well regarded designer for a competing cam company to Comp, and he deciding to "show off his design chops", and give me "more" of what I was seeking.

Interestingly, he stated he also designed for full original-equipment levels of durability.

Usually, when seeking short duration and max lift, you compromise durability, to a slight or great extent, depending on your cam designers ability and capability of translating that into an accurately made piece. There are known issues: the Volvo oiling system tending to not supply enough oil, and that the best wear reducing additives no longer being added to oils in representative quanities. Likewise, there are known solutions available tp the well informed b20 engine builder: oil additives, ceramic faced lifters, nitriding of the cams, machining for larger diameter lifters, and most easily, chosing the right valve spring. I regard the Isky-IPD double valves springs as gross excess. Depending on the machine shop cutting the seats, and tolerance stack up, you can see over 115 on the seat, and 210 over the nose. My personal car uses original Volvo lifters, a nitrided cam , and Crower-vended springs intended for air cooled VW applications. The installed pressures were about 90 and 150 over the nose, and a titanium retainer was used, as these spring pressures are close to minimum, and also because they looked cool and set up at a slightly better height than their steel equivalent. The spring retainer pkg does allow up to .620" lift, if that were ever required.

I will state that trading off durability for quick valve motions offers only subtle & theoretical gains, so I am not encouraging that for the vast majority of users.

Lastly in the photo, I've included stats for one of VPD-John Parkers cams. I believe this is the one referred to as the SP? Very nicely chosen lobes, it would appear. They should "crutch" the fact that there is little high lift exhaust port flow. Hopefully John doesn't mind my posting the measurements. I can't imagine that showing these would prevent anyone from buying his product, and I can imagine it may well encourage some sales. Hopefully these do not suffer from any delivery delays. The lobes used probably represent a well chosen point where quicker valve openings show diminishing returns vs wear failure possibilities.

It can also not be forgotten that the timing (lobe separation angle as well as overall timing)of the lobes to the crank position vary with different grinds. For example this is one reason the Isky grinds can act "larger" than the OE Volvo ones while appearing somewhat similar by charted measurement.

Best regards to George, Cameron, Paul, John & the rest,

IR

|