|

|

|

After I replaced the tailgate wiring harnesses a couple of weeks ago, I realized I had no brake lights on the '92 245. I did the simple checks, and researched the problem here, which prompted me to recall that my departed '91 had the same problem a few years ago and the bulb-out sensor was the offending item. Not a great selection of junkyard Bricks out here in the desert and I was pressed for time, so I ordered one from fcpgroton and a few days later I was back in business.

So now I have two failed bulb-out sensors on my workbench. I've looked them over closely with a 5x loupe and I can't find any cold solder joints, burnt areas or any other obvious sign of damage. Does anyone have an idea of what the common failure mode of these is?

--

In God We Trust. Everyone else, keep your hands where I can see them.

|

|

|

|

|

If you are attempting to run trailer lighting without a powered adapter you will blow the bulb out sensor. It is not designed to take the load. The root cause of the problem is an overload that caused sensor failure. Probably one or more open or burned resistive coils. Certainly not worth the effort to fix but Bentleys has a diagram of the sensor.

--

David Hunter

|

|

|

|

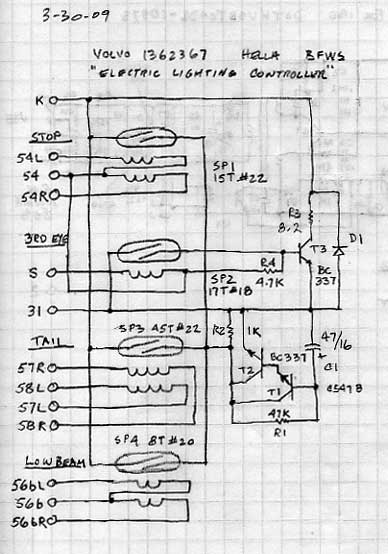

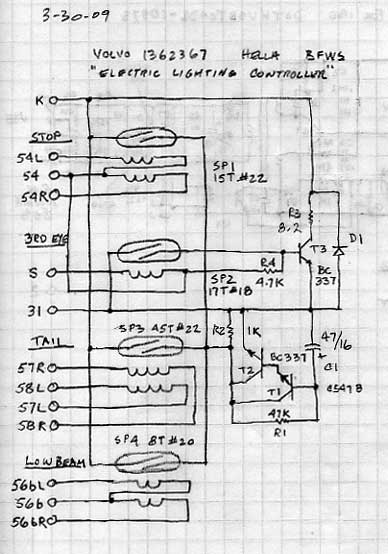

Bentley has a copy of Volvo's sketch. Here's what is inside:

--

Art Benstein near Baltimore

It's always darkest before dawn. So if you're going to steal your neighbor's newspaper, that's the time to do it.

|

|

|

|

|

Interesting...

In my case, none of the brake lights worked, so I suspect some element common to the 3rd eye and stop lights is the offender. I'll take a closer look when I get a chance.

--

In God We Trust. Everyone else, keep your hands where I can see them.

|

|

|

|

That's an excellent clue, and very likely suspect given the total current that part has to conduct. Just follow the metal from pin 54.

--

Art Benstein near Baltimore

SUCCESS:

At age 4 success is . . . not peeing in your pants.

At age 12 success is . . . having friends.

At age 16 success is . . . having a drivers license.

At age 20 success is . . . going all the way.

At age 35 success is . . . having money.

At age 50 success is . . . having money.

At age 60 success is . . . going all the way.

At age 70 success is . . . having a drivers license.

At age 75 success is . . . having friends.

At age 80 success is . . . not peeing in your pants.

|

|

|

|

|

You bring up a very interesting point.

I have read about these getting blamed for circuit failures. But in my realm of thinking on how these work, they shouldn't.

I have looked inside them to find no moving parts like a relay has.

I see that they have only coils of wire. They should not be carrying the actual current of the cicuit. These are parallel to the operating circuit. Like a shunted circuit.

One coil is wound one way and one wound the other way. Each representing half. Each one side of the car.

The current that travels through them cancels each others, magnetic field.

If only one of the coils (half circuit) becomes unbalanced (bulb out) that would be induced a current field into a third coil of wire that is in the center of those two other coils.

That coiled wire tranfers that induced current. It is routed to the warning light bulb through it to ground. Light on!

These wires have a thin insulating coating on them. They actually call this wire, magnet wire.

It is used in relays and transformers. I know of failures that can be caused by vibration of the wire themselves. I don't mean by the shaking of the car but the current flow itself passing through them. Heating and cooling too!

Ever heard a street pole transformer hum outside your house. AC or 60 cycles per second causes the hum. That's what we hear. It also is moving the wires inside it.

I know we have 12 volt DC. But it is generated by a AC dymo i.e. alternator. The DC is not a pure smooth DC. The diodes in them are a brute force cheap device. The auto manufactures use the best cheap stuff they can get!

The battery absorbs a lot. In some cases a capacitor has to be added to keep hum out of the radios power circuit. Called a choke or filter to electronic buffs.

Under certain low speed, bad ground and or high load conditions the alternator does pulse a more coarse wave than normal causing the whole system waver.

I surmise that it may be something like this this that the electrical designer discounted in the specs. for the coating and winding of the magnet wire.

Operating conditions vary per car and the quality of the componets in general through out the spectrum of manufacturing.

In other words: Some do, some don't! Have a problem!

You may not be able to define it as a broken solder joint or unsolder wire.

Its most likely leakage within the coils to the other coils. A device called a megometer that induce a voltage may be used to test insulation. The highest ohm meter sensitivity may show something inside. Then it would be all about rewinding and that would be a tough repair!

Replacing it was the best thing other than check out your electrical charging system and maintenance habits. A common thread between the two bad sensors.

Good Luck, cause it's all just a guess!

Call on Bricksters. Jorrell and Art Beinstein. They may have better thoughts since their our electronics masters.

Phil

|

|

|

|

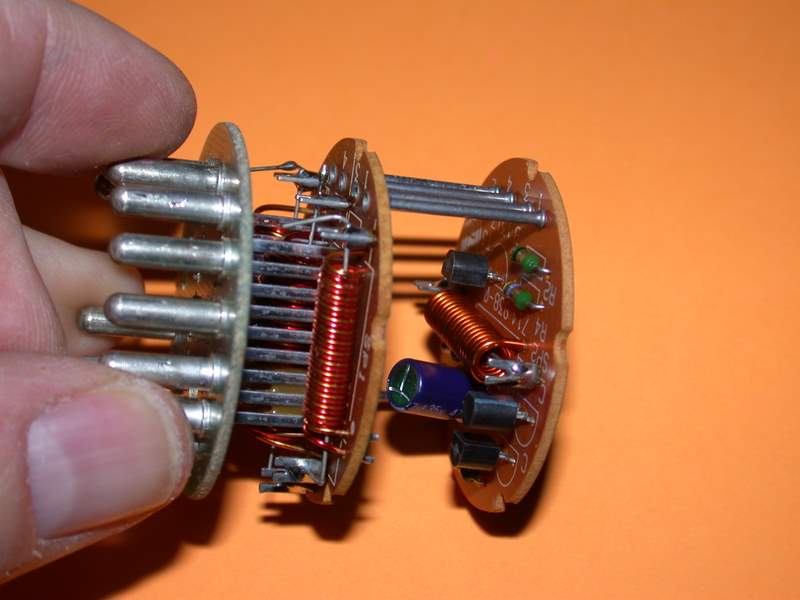

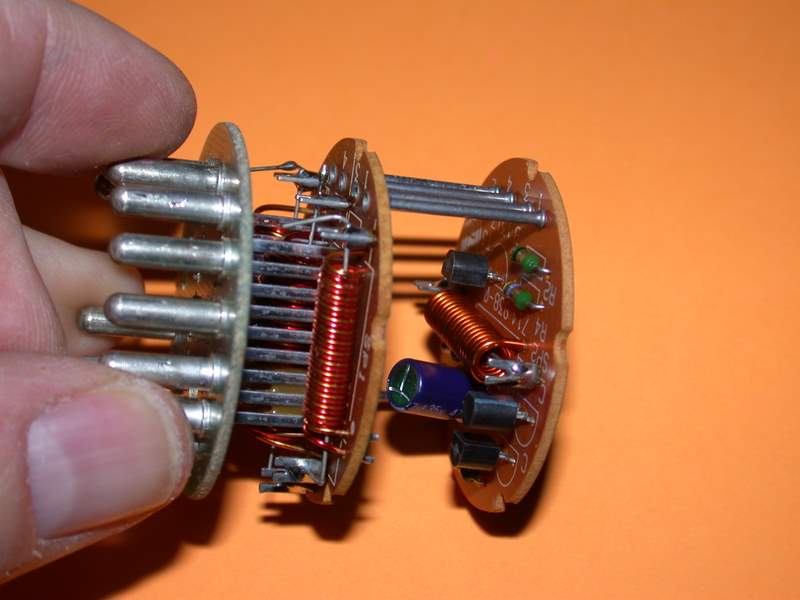

Only two modes of failure I've seen so far are (1) the cracked solder joints in the many connections the lamp current must traverse, and (2) the overheated sense coils in the tail light portion David Hunter refers to, which could easily be caused by trailer wiring, or as I have seen, improperly installed dual filament bulbs and attempting to troubleshoot melted aftermarket sedan lamps.

Here's an example of (2) where the two tail light windings are shorted together. This doesn't keep lights from working - it just keeps the warning light on when there's nothing to warn of.

--

Art Benstein near Baltimore

If you think nobody cares if you're alive, try missing a couple of car payments.

|

|

|

|

|

Your description of the sensor is partially correct. It's simply a reed switch in the center that closes a circuit to the failure warning light when it senses a load mismatch in paired coils.

Even at idle alternators output 3 phase at a much higher frequency than 60 HZ with full wave rectification using high capacity diodes. Ripple is effectivey smoothed by virtue of being connected to the battery and has no effect on the sensor.

--

David Hunter

|

|

|

|

|

in my experience, the solder failure is in the Pins that connect the two Circuit boards.

--

'75 Jeep CJ5 345Hp ChevyPwrd, two motorcycles, '85 Pickup: The '89 Volvo is the newest vehicle I own. it wasn't Volvos safety , it was Longevity that sold me http://home.no.net/ebrox/Tony's%20cars.htm

|

|

|

|

Tony, I will back you on this. As you can see in this inventory, 19 of 67 connections necessary for a tail light are associated with the BFS. Tail light problem chasing

It might take an 8x loupe.

--

Art Benstein near Baltimore

Before you criticize someone, you should walk a mile in their shoes. That way, when you criticize them, you're a mile away and you have their shoes.

|

|

|

|

|

My day is complete - Art has replied.

Actually, I think I'll try one of the microscopes at work to look for bad solder joints. FWIW, the latest failed one had a faint "let the smoke out" aroma.

--

In God We Trust. Everyone else, keep your hands where I can see them.

|

|

|

|

Smitty, if you want to fix those, you can do it easily, if the symptoms for both were that of failing to pass current to the bulbs being monitored. Those are just broken connections. On the other hand, any smoke would likely be a different mode of failure, that would normally result in the warning feature lying to you, not impaired lighting.

To repair them (even to fully inspect them), you really have to disassemble them completely to three boards. That means desoldering the stilts that hold them together - the five round pins first, and then the 18 flat pins that are lap-joined to the board with the plug pins. Those flat pins and the L-shaped ends at the lap joints are where I find the cracks. A vacuum de-slobbering station makes easy work of this compared to a squeeze bulb and fluxed braid.

--

Art Benstein near Baltimore

There are two theories to arguing with women. Neither one works.

|

|

|

|

|

Well Art, I have to say I'm all wet on this one!

I don't even remember the sensor I had even looking liked the one you show.

I was not aware that they used a reed switch inside the coils or the circuit boards.

As I remember, the one I looked into had a lot more coils and were vertical in a circle. Guess, I must have dreamed the whole thing.

Still thought this sensor was a shunted device. Guess a shorted circuit would draw more current through the parallel wires and those coils.

As far as the hertz thing. I thought dynamos had to turn something near of 60 x 60 = 3600 rpm. Multiples of or divided by the number of poles built into armature vs field windings. Several three phase circuits can be milked out of one generating unit. Of course I'm talking about steam/hydro driven powerhouse units that I'm most familiar with.

My experience with movement of windings was with a problem on GE Dynamos in the early 80's. In my thinner days I was elected/selected/volunteered to slide around in between the inner housing and the stator windings to install belly bands to stabilize the bars that hold the windings. Barely enough room to breathe between them. Still had to tighten up band bolts. Found out that I was not claustrophobic.

There was a unit in Redondo Beach Ca. that blew/cracked open a end bell housing. That's when I also found out about the use of Hydrogen gas. It's used to cool the windings. Moves more BTU's per pound next to water. Does have a slight draw back though if it gets mixed with something else! But then again, so does water?

Then again water should burn. H2O? Someday it may become economical.

In this case it was excessive heat (shorts) caused excessive expansion of gas and the joints. Didn't blow up really but it wasn't pretty.

The statement made by Mr. Hunter is dead on. Below 60 to far above is correct.

We now have quartz crystals and atomic radios for our clocks. Counting the cycles as some AC appliances have done and some still do. Has change some of that dependence.

This bring us back to our discussion of AC (Telsa) vs DC ( Edison and Franklin). Then the aircraft industry and the military using 400 hertz to save size and weight.

Of course you know all this stuff. You said you would like to hear more about my thoughts on these fellows.

Since I was guessing at a "DC ripple" theory. That's why I called out in my post for you or Jorrell to reply.

Glad Smitty is happy!

Little did I know we have Mr. Hunter as a another person so well informed. This is a good site for swapping and sharing knowledge isn't it!

Maybe a little confusion (for me) mixed in as well.

It all makes me Happy!

Phil

|

|

|

|

Hi Phil,

Don't throw a wet blanket over your memory. Like so many posts on a car made for 19 years, the year is important, but for some reason original posters are in such a hurry to get their posts made, they often forget the dropdown feature selecting the year. It keeps us aware of the context throughout all the replies.

Smitty has a 92. Your memory goes back before 86, and sometime before the third eye these sensors were much simpler. When I first started trying to help on this board, I too had only seen the type that was built without stacked circuit boards. The coils were soldered into the pins. There were no transistors to account for the high mounted brake light or the warm-up delay. And based on that I told some brickster the BFS was a very unlikely place for an open circuit in the lighting path. Yes, I found out the year is important.

Hydrogen peroxide - twice baked water?

--

Art Benstein near Baltimore

If your sister hits you, don't hit her back. They always catch the second person.

|

|

|

|

|

Thanks a lot Art. I feel much better now. I guess it was my '78 that I looked into out of curiosity. I have never had one fail as of yet!

I was just at a P&P and made a nice find. A small round tachometer. This is a spare since I have one in each of my 84,86 and 91.

I may have to pick up a bulb sensor but how will I know if its any good?

I plan on going back tomorrow since there was some good choices with the influx of the clunker plan. I plan on getting some fenders for my old '74 Ford XLT truck. Like a Volvo there are several years that things interchange.

There was a '91 wagon that was fairly well intact. I forgot to check out the trans for a 5 speed. The speedometer says 132k. I suspect it stopped though. That's too low.

The nice white headliner had marker pen graffiti from front to back like a LA freeway wall. Made me sick just to look up at it.

Hydrogen Peroxide! How do you know this stuff? Baked twice? Is that the chemist coming out in you?

Guess that's my problem. I just try to boil it! My wife has made twice baked potatoes. When I do meat once, they are hockey pucks!

I read water can be separated but more energy goes in than what comes out.

My memory thanks you again.

Phil

|

|

|

|

|