|

|

|

I am sure this was answered before, but I would like to double check that I am on the right track. 1991 240.

I have spark (verified with an inline spark tester), have fuel injector pulse (verified with a noid light). When I put a jumper between fuse 4 and fuse 6, I hear a hum. I think it is just the in-tank pump that I hear. When I touch the other pump and connect the jumper, I don't feel anything.

So, my question is, should I feel the pump vibrate, or hear it as I am under the car, when fuse 4 and fuse 6 are connected? And if so, it's down to two things, either the pump, or the pump wiring, correct?

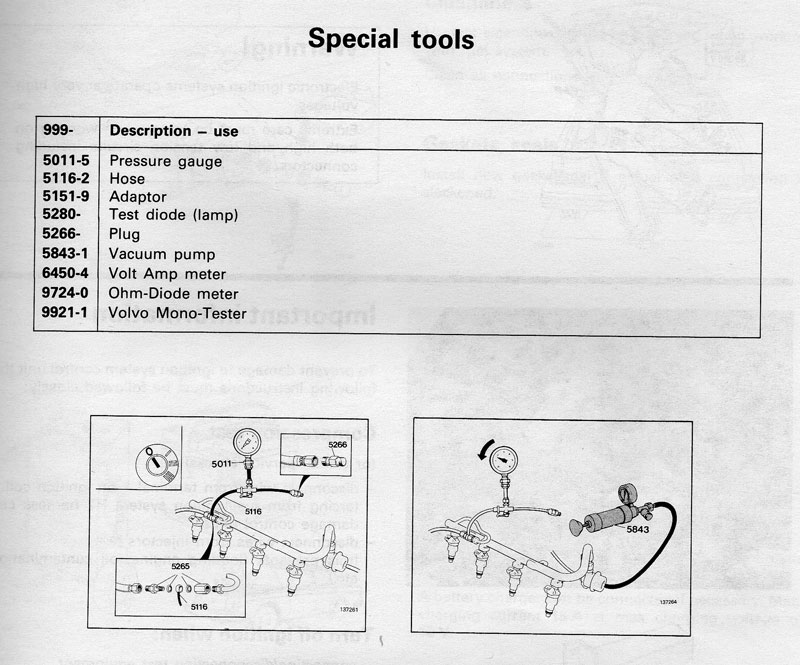

I can't check the fuel pressure because I don't have a valve on the rail, and if I disconnect the rail it turns out I don't have a right fitting to connect my fuel pressure gauge.

Thank you in advance.

|

|

|

|

Missing picture:

--

Art Benstein near Baltimore

|

|

|

|

|

Thanks, Art.

I did what you suggested, and the results are not what I expected.

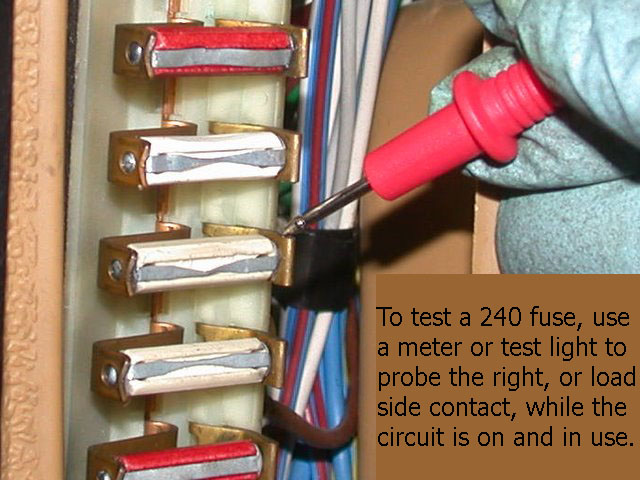

First, there is battery voltage on the right side of fuse 6, if I connect a jumper from fuse 4 to the left side of fuse 6.

Then, there is battery voltage on the orange wire of the MAF sensor when ignition is on.

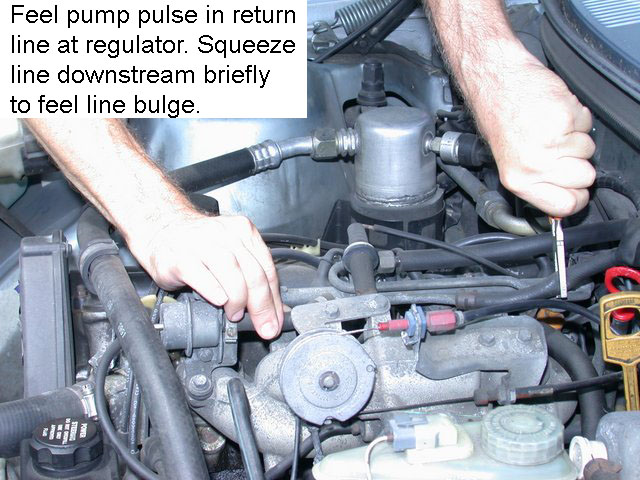

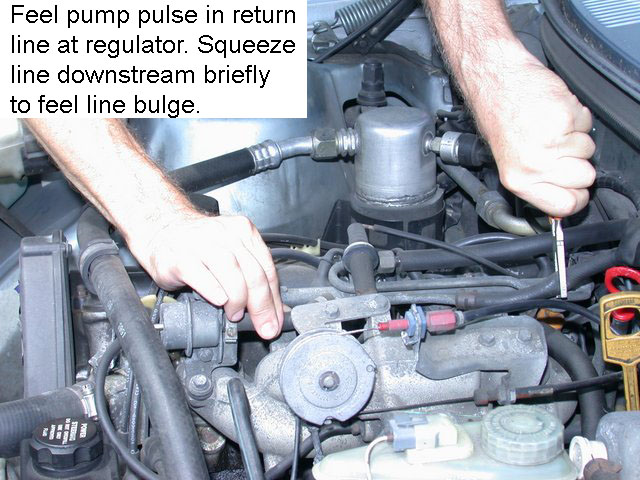

But when I pinch the return hose and have my assistant connect the jumper, I feel the bulge in the return hose. That I did not expect. Is this test conclusive? I.e. telling me that the main pump is working? Or can it be that the in-tank pump generates enough pressure for me to feel the bulge, but not enough for the engine to catch?

Thank you again.

|

|

|

|

Not what I expected either. But I forgot to suggest the very first step -- be sure the cam is turning.

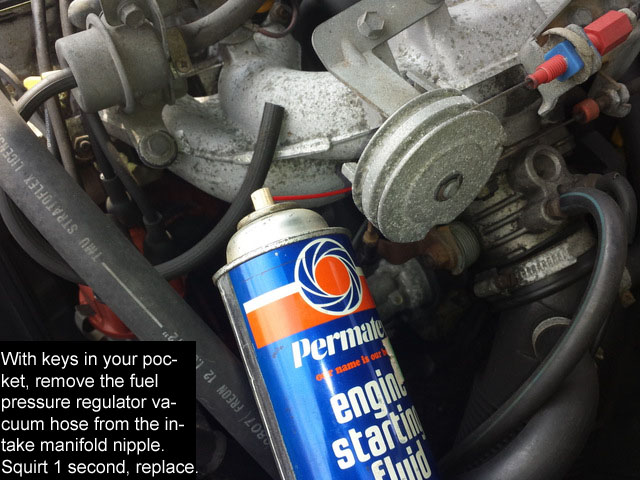

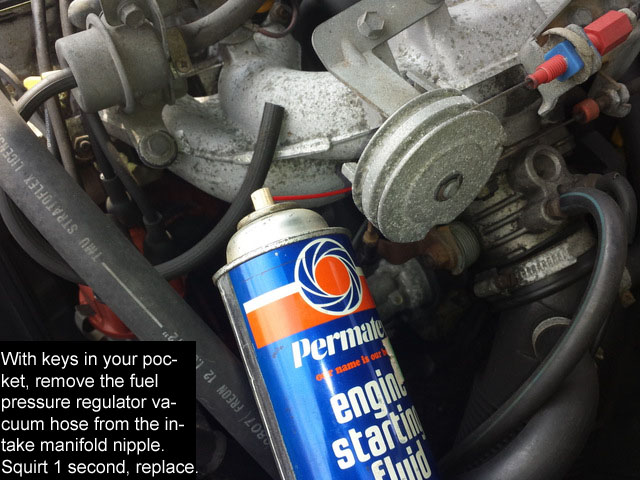

If it is, go back to your original assertion that spark is OK. Check that by using a bit of flammable spray, into the manifold. If you feel the pressure in the return hose, even a wide-open failed fuel pressure regulator would leave enough pressure in the rail to squirt fuel, so see if it will catch at all with another source of fuel.

--

Art Benstein near Baltimore

|

|

|

|

|

Lacking my assistant to crank the engine as I shine the light into the oil filler hole, I proceeded directly to step 2. Skirted some starting fluid into the manifold, tried to start. The engine caught and ran for 1-2 sec.

This rules out the timing belt, doesn't it? Besides, I did see the spark clearly using one of these https://www.harborfreight.com/in-line-spark-checker-63590.html.

If you still think I should double-check the timing belt, does the distributor on this engine run off the timing belt? Can take the cap off and crank it and see of the rotor moved?

|

|

|

|

Sorry I skipped your question about checking the timing belt by looking at the rotor in the dizzy. Yes you can do that, but even more easily, the same observation can be done through the oil filler hole by noting the cam lobe position before and after blipping the starter.

Not an issue for you, since running with starter fluid proved you have compression, therefore cam timing, and the rings probably haven't been washed free of oil by leaking injectors.

--

Art Benstein near Baltimore

|

|

|

|

Yes, that rules out the timing belt and a spark problem. One reason the spark cannot be ruled out with a spark checker, or seeing it on a plug, is with EZK ignition, a fault with the CPS or controller can cause spark to be timed wrong. Not in your case, though, since it ran on starting fluid, the problem is clearly a fuel issue.

Time for a little history. Did the car die on your daily commute? Or is this a project that hasn't run for some time? Given you have fuel pressure you can feel in the return line, and pulses delivered to the injectors observed with the help of your 'noid light, there's only one thing that I can imagine -- your injectors are all clogged. Not an outlandish conclusion if the car's been sitting. Pull a plug or two and sniff, to be sure, then pull the fuel rail. Run the injectors without cranking the engine by using the OBD mode 3 test. The residual fuel pressure after running pumps alone with the jumper will be enough to see them squirt.

--

Art Benstein near Baltimore

|

|

|

|

|

The car is not a project, but it is driven infrequently. It failed to start one morning. Then it started a couple of days later when I was going to work on it. I moved it literally just down the driveway, where it sat for another couple of days. Then it failed to start. After that it sat for two weeks until I had the time to look at it yesterday. Was running pretty smooth before that, so it is hard for me to imagine the injectors being all clogged up. Maybe two of them or something, and it's enough for the car not to start?

I will pull the spark plugs out and sniff. Then pull the rail off and see what I see. Back shortly.

|

|

|

|

What you say makes sense to me. It brings this funny story to mind:

"I am reminded of a story from years ago when GM throttle body fuel injection was a new thing on cars. A customer had his two-week-old Cadillac towed into the dealership with a "no-start" problem. For two weeks, every technician at the dealership worked on it trying to start it but to no avail. We checked for spark, compression, timing; pulled codes; set codes; checked fuel pressure; checked to see if the bumpers fell off... Every conceivable thing was done to this vehicle we could think of and still no start. Finally, one of the techs decided to check the fuel spray/pattern from the throttle body. He got a bit of the spray on a piece of paper, tried to light it with a cigarette lighter, and it did not ignite. The tank and fuel system were drained, filled with fresh fuel, and the car fired right up.

After contacting the owner, who then spoke to his younger children, it was discovered that the kids were playing "gas station" with the new Cadillac and garden hose. ---Bruce in Oregon via Rock Auto"

--

Art Benstein near Baltimore

|

|

|

|

|

Thanks, Art, unfortunately I already knew the story, and don't have appropriate age children in the house to account for something like this.

I pulled spark plugs 1 and 2 out and sniffed them. They smelled of gas. Not badly fouled up or anything, just regular looking 2 year old spark plugs. I stopped there.

Then proceeded to pull the rail. The injector o-rings were pretty stuck, and some leverage on the rail was required. After that, I saw that one of the plastic injector end cups, don't know the proper name, did not come out, and as a result the yellow washer that's above it took a walk down into the bowels, as did the fuel injector when I took it off the rail. Long story short, I found everything and put the injector back on the rail, now will go run "level 3 diagnostics".

|

|

|

|

|

Finally some clarity.

First, level 3 diagnostics does not work with the rail off unless the two ground wires under the rail bolts are grounded. I took a detour diagnosing the OBD ports (all tests came back negative of course), until it occurred to me that the ground wires probably needed to be connected for this to work. And they did.

Next, diagnostics. The injectors were clicking, but no fuel was coming out.

Here's where I may have made a mistake, please tell me if I did. Thinking there was perhaps not enough residual fuel pressure in the rail for any gas to come out, I connected fuse 4 to to fuse 6 for a bit, to pump some more fuel in. I did that while in diagnostics mode.

After this procedure, I could no longer hear the pump hum when connecting the two fuses. I did hear the hum when I disconnected the main relay and connected terminal 30 to terminal 87/2 of its harness. I don't know what to make of this.

At this point I was getting pissed off, and decided to pull the main fuel pump off. The in-tank one was replaced last summer, I had a new Bosch main pump and a new Bosch filter sitting on the shelf, my rationale was that they should probably be replaced at this stage anyway on a 30 year old car. Pretty sure the ones I pulled off were original, they had plenty of that gooey black factory undercoating on them.

Put the new pump in, and the car started, and ran smoothly. I did not drive it, I was late for dinner already, I just let it idle as I put the tools away. Will drive it tomorrow (if it starts that is :).

So, two things at this stage.

First big thank you to Art for holding my hand through this. I learned a lot.

Second, do you think I somehow damaged my in-tank pump by connecting fuse 4 to fuse 6 while in diag mode?

I realize that I could listen to the in-take pump if I expose the port on top of the fuel tank. But my car is a wagon with a 3rd row of seats, it's a real pain getting to that pump port.

The car has about 3/4 tank in it, so I understand it will run even if the in-tank pump is not working. I guess I could just let it run and see.

I also heard that you can push a length of hose into the tank through the fill hole, and listen through that. I have not tried it, I only just recalled it.

Thank you again.

|

|

|

|

The mystery remaining, for me, is this: If the problem was fuel pressure at the rail, which you could not measure with a gauge, how was it possible you could feel a restriction on the return line? With a working regulator, the return line has zero pressure until the rail has at least 3 bars in it.

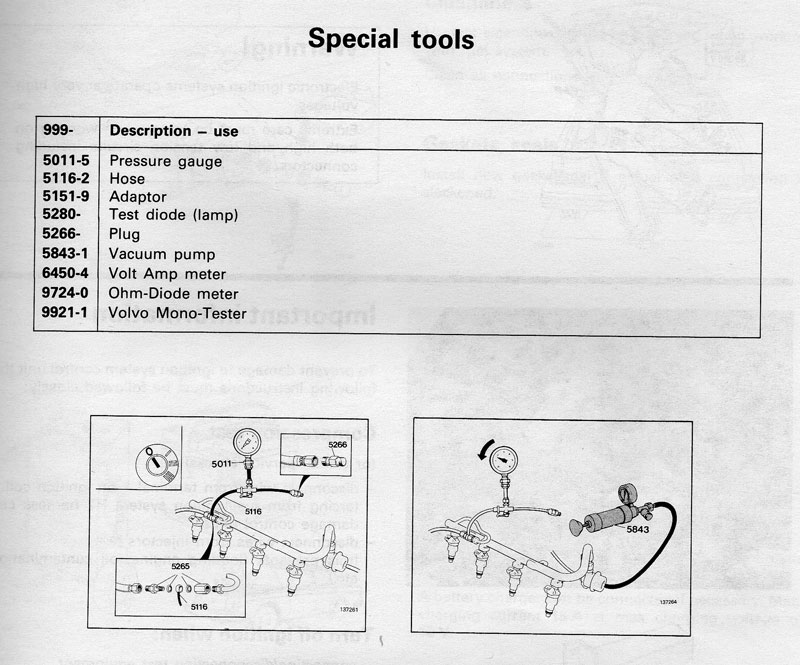

Getting a gauge on the rail was my first Volvo challenge back in '99. That problem was how I found the Brickboard, checking usenet groups for Volvo help, after several trips to the auto parts stores and a lot of rummaging through fitting selections. I got some advice from a helpful member who still posts here, essentially, go to the junkyard, get a fuel rail, and make an adapter.

Seriously, I don't know how I'd get along without it, although squeezing the return line is better than no gauge at all.

You can't damage the in-tank pump by any combination of electrical connections in the car. Unfortunately, those pumps aren't made very well, and often have a much shorter life than you'd expect. And just hearing it run isn't a confirmation that it is supplying the main pump with fuel. Scroll through this: In The Tank

"After this procedure, I could no longer hear the pump hum when connecting the two fuses. I did hear the hum when I disconnected the main relay and connected terminal 30 to terminal 87/2 of its harness. I don't know what to make of this."

This worries me. Most folks with a '91 have gotten rid of the pink-label -561 ECU long ago, but if you have it still, the fuel pump relay driver transistor is prone to failure, with one theory that the trigger is a poor ground for the system at the fuel rail. The white-label version, or the 951 used in the '93 is robust, with new circuitry.

However, that 1-second buzz of fuel pump is not initiated by the same connection you make jumping 4 to 6 if the key is already on, as when you are using OBD.

You did a lot of work yesterday. Normally, these cars take weeks to fix on the internet.

--

Art Benstein near Baltimore

|

|

|

|

|

Thanks, Art. I did read your In The Tank writeup last summer when I replaced the in-tank pump. Looking at that, and the wiring diagrams, I could not see how I could damage the in-tank either, but what do I know, I've replaced one fuel pump in my career. Well, two now :).

I do have a pink label ECU in the car, but I have the trim pieces out, and the ECU just hanging there. Early in this process, I was under the mistaken impression that my fuel injectors were not firing. I had arrived to that conclusion by measuring voltage between the two injector contacts for cylinder 1, not realizing that the pulse is so short that a voltmeter would not register it. Then I bought a noid light and saw that I was on the wrong track. But I did get the ECU out and did a good subset of the tests outlined in the Bentley, before I bought the noid light.

It also just so happens that I have a white label 951 sitting on the shelf. The thing reportedly came out of a running '89 740. It is untested, untested by me that is, but would be a snap to plug it in and see at this stage. Which I will do when it stops raining.

I got the ECU because I had heard bad things about the 561, and what you're saying confirms it, so if the 951 works that's the one I'll leave in the car.

For the future, I'll look into the adapters for the fuel rail. Don't know about the finding a rail at a junk yard though, we all know how old our cars are. But if I end up going that route, maybe a rail from a newer car? I understand the rail was updated in the later years to include a test port.

Thank you again for all your help. I'll report back.

|

|

|

|

|

Okay, the car started fine this morning, the new (new to me that is) 951 ECU is working fine, the car did fine on the test drive. Just hang up the ECU where it is supposed to be, put the trim pieces back in, and I'm done, hopefully.

|

|

|

|

Thank you for your thorough responses and wrap-up, making this thread valuable to others especially.

The long-given advice to keep a spare ECU and AMM still holds true for Volvo LH cars, I think. My strategy was to keep the white-label -561's and -951's on the shelf and run the pink-label ECUs until they died. Easy for me, because we have multiple LH2.4-running cars (which one should get the spare?) and I could explain to my kids how to use the jumper kept in the glove box when the older -561's finally died -- and they all did eventually.

Having a tested spare on the shelf is important for ruling out these two pricey parts that are not easily eliminated in testing by other means. There are not any tests that will validate an ECU or an AMM using a multimeter, despite what Bentley makes believe. You might get lucky to prove one bad, but you can't prove one good.

Sure, there were days when I could count on 5 or 6 240's being in the local pick'n'pull yards. I miss that for sure. Since then, the 14mm adapters are more available without having to butcher up a fuel rail. The 92+ rails with the Schrader aren't much help anyway, unless you have a tight 90° adapter.

Here's one that looks helpful. Maybe not a complete kit, but at least what you need to make the connection:

https://www.toolsource.com/volvo-tools-c-1321_831_1591/volvo-fuel-injection-adapter-14mm-lhjetronic-p-55212.html

Here's my glove box kit. This example is made from junk yard parts.

--

Art Benstein near Baltimore

|

|

|

|

|

Thanks Art, I'll order this adapter and see if it's any good. For $20 shipped it's worth trying.

|

|

|

|

|

Hi,

Is there any possibility that some rascals have built themselves an adobe bungalow inside your exhaust system while you've been social distancing ?

I don't know if you can feel the air moving out of a tailpipe while someone cranks the car because I've never tried it, but I do know that a 240 with a completely restricted exhaust will run with 1, 2, or 3 spark plugs in the engine, but not with 4.

regards, Peter

|

|

|

|

|

Your injector injectors aren't opening.....

|

|

|

|

|