|

Hi Dave,

In general terms, there might be a tip in the words of Alessandro Mazzucotelli (1865-1938), an Italian blacksmith whose work I admire.

" Iron should be treated like a woman; she seems hard and terrible, but with a little warmth she turns soft like wax. And when it seems to rebel, do not mistreat it and hammer it furiously. No! You have to treat it gently and caress it."

He's talking about forging but the same principle applies. Resist brute force and you wont break anything. With patience and the right approach, you'll be able to have your way with it.

Rust expands when it forms between male and female threads, and exerts a tremendous pressure between them. It must be worn down with some movement before they can turn.

The expansive force of heating and the contractive force of cooling can provide this, but the heat from your engine is insufficient. If you don't have an oxy fuel torch, a Mapp gas cylinder on a Benzomatic torch might be enough. It might take multiple cycles with applications of oil in between. Resist turning the nuts or studs when hot because they are weakened and prone to galling.

You can also mechanically stimulate them by tapping on the nut faces with a small ball peen hammer, or a ball headed drift.

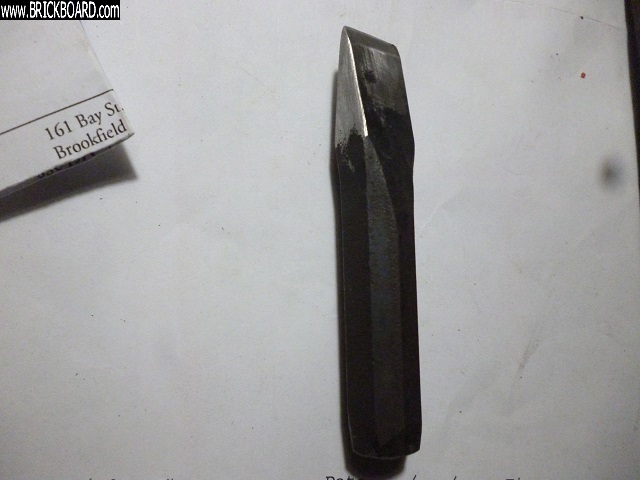

I've had considerable success with a stubby cold chisel that I made.

It's 3.5 inches long, short enough to swing a 2-3 lb hammer in the space available. I make multiple small cuts into the nut face which in theory expands it a bit. The shock may also be a factor because the studs more often than not come out of the engine with the nuts attached.

The chisel has a 30-35 degree as opposed to the normal 60 degree. Most cold chisels are supplied much softer and weaker than they are capable of being. They want them to deform instead of chipping or cracking if they're abused. This chisel was made harder and stronger to handle the small angle and retain it's cutting edge.

I've never had to go much farther than what you see. If the cuts are too deep it begins to be difficult to get a socket on. It may need to be hammered on. The nuts could be completely cut off without any damage to the stud.

As to the studs in the outlet of the manifold, you'll have to see what you can do. Sometimes there's no alternative but to heat up the studs and the area around it to red and let it cool slowly. In the worst cases, that might have to be done more than once.

regards, Peter

|