|

|

|

All four NGK BPR6ES spark plugs in my B230FT are completely blackened and soaked with gasoline. Obviously a rich fuel mixture, right?

Cylinder compression and leak down testing shows engine mechanical is sound.

Full engine rebuild completed one year ago.

My mileage is around 14-15 MPG. Performance is very good. Cold start-up is immediate, but idle is poor until plugs and cylinders are cleared of apparent excessive fuel.

The fuel injectors are firing (per noid tester), and their o-rings are new.

The Secondary ignition is also firing correctly. The rotor, cap and wires have all been replaced with Volvo OEM.

FPR replaced a short time ago, which also did not improve the situation.

You may assume the fuel system is completely clean and without any debris.

What am I missing folks? Gotta be something obvious, I’m sure.

|

|

-

|

|

|

Hi again everyone.

Regarding the Coolant Temperature Sensor I need to examine and/or replace, which sensor is it?

There are two in the block on the left side, one has 2 blade type connectors, and the other sensor has 2 bullet type pins.

Volvo calls them both "Coolant Temperature Sensor".

|

|

-

|

|

|

It’s the further aft one and is kinda hard to reach. It’s back at about cylinder 3.

Are you planning to do a temperature vs resistance test?

|

|

-

|

|

|

Hey Chris,

I would appreciate knowing the testing procedure for both.

I have ordered a new Volvo OEM sensor, but would like to test the old one.

John

|

|

-

|

|

|

Dear Townshend Act,

Hope you're well and stay so. The test values for the Engine Coolant Temperature Sensor (Part #1346030) are:

-10°C = 8260 - 10560 Ω

+20°C = 2289 - 2720 Ω

+80°C = 290 - 364 Ω

(Values in Ohms).

Source: Volvo, Pocket data booklet - Cars (700, 900, S/V 90, 850, S/V/C 70), 1991-1998; pp. 33-34.

As the sensor is hard to access, I reasonably expect you'll replace it, even if the in-service unit is within specification. If so, keep it as a spare, noting on it the date it was removed.

Hope this helps.

Yours faithfully,

Spook

|

|

-

|

|

|

Hey, thanks Spook for always providing us your experienced insight on these older Volvos.

Can you assist me by saying which sensor should I be dealing with?

Volvo shows two coolant sensors for my 940T with P/N 1346030 and P/N 1362645. Both are listed by Volvo as "IAT Sensor". One I know is for the temperature gauge & the other is for coolant temperature to adjust fuel mixture, but I can't tell them apart by part number alone.

Chris earlier directed me to the proper location of the coolant temperature sensor controlling that controls fuel mixture, but which one of the above part numbers is that sensor?

Thanks in advance.

John

|

|

-

|

|

|

Dear Townshend Act,

Hope you're well and stay so! The Engine Coolant Temperature (ECT) sensor - the signal from which enables the Engine Control Module to adjust the fuel supply as the engine comes up to operating temperature - is Part #1346030. The Bosch part number is 0 280 130 082.

The ECT sensor is located under the third and fourth intake manifold arms ("runners"), i.e., towards the rear of the head.

The sensor that provides a signal for the instrument cluster's temperature gauge is Part #1362645. It, too, is located under intake manifold arms ("runners"), i.e., towards the front of the head.

Hope this helps.

Yours faithfully,

Spook

|

|

-

|

|

|

Spot-On answer. Thanks for the clarification Spook

|

|

-

|

|

|

They would both be tested the same way but I don't have the resistance values for the sensor that feeds

the temp gauge. If your temp gauge is running at about mid-point then it's sensor is probably OK.

You'll need:

A pan of water

A stove

A cooking thermometer

An ohm meter

A coat hanger

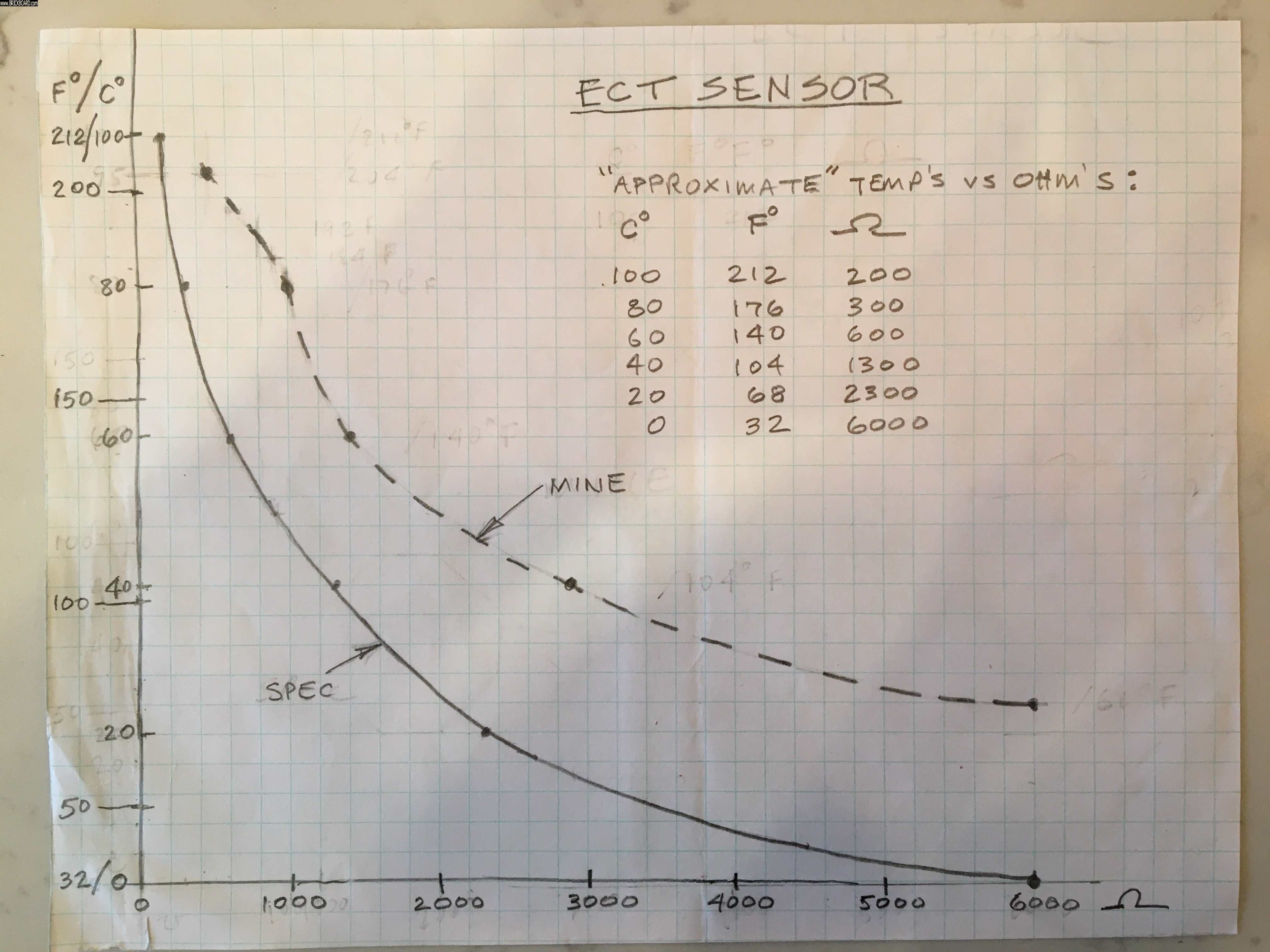

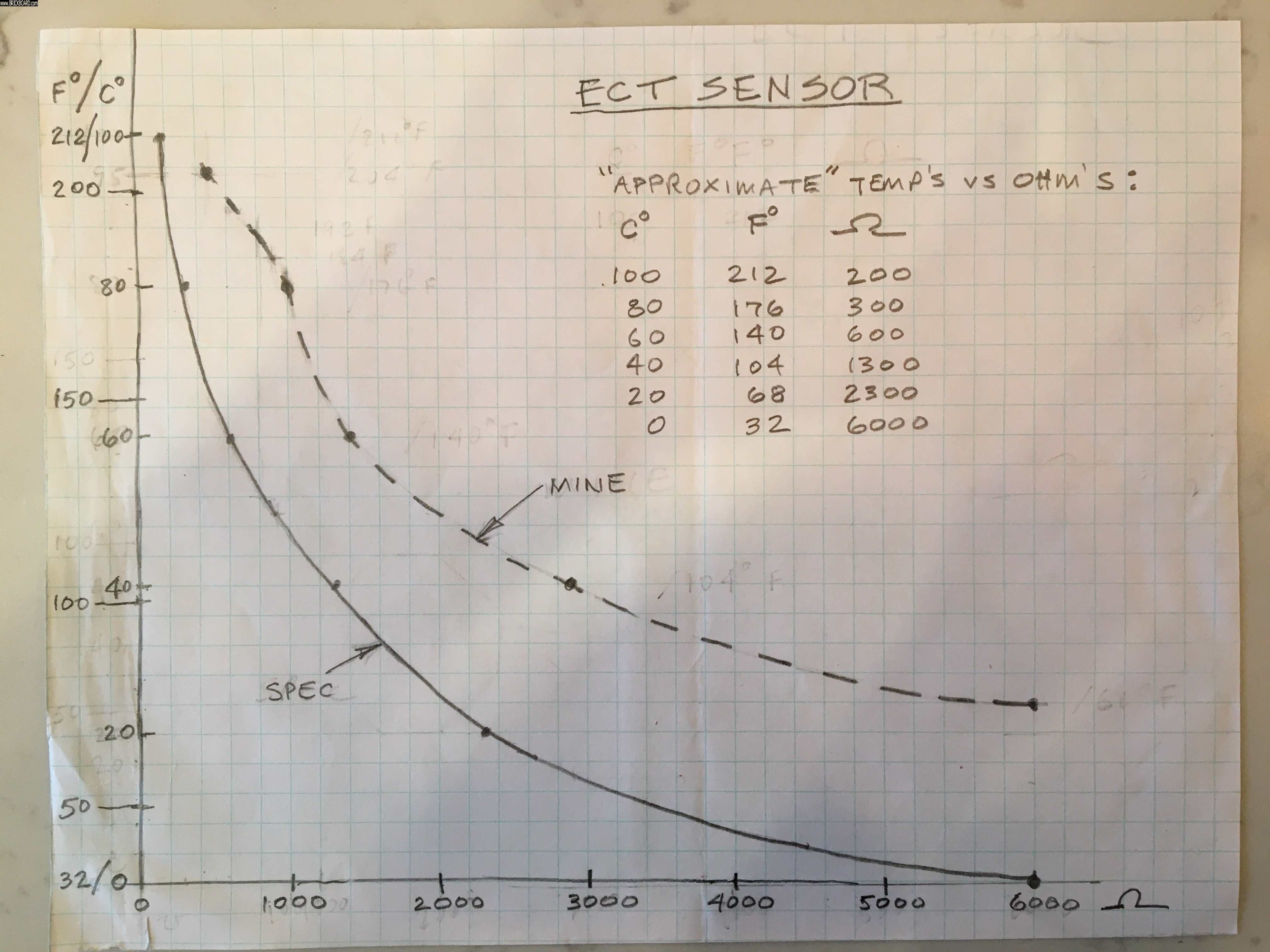

Bend up the coat hanger so that it hangs over the edge of the pan and suspends the sensor with the

sensing section submerged in the water - just like in your engine. Connect the ohm meter to the sensor

and make sure you have continuity. Heat up the water to various degrees, monitoring with the cooking

thermometer. Watch the ohm meter move has the water temp rises. Compare water temp vs ohms against

the (crude) chart below. I created it many yeas ago when I was going through what you're going through.

The dotted line charts my observed values when testing the old sensor. The solid line is the spec that you

want to see in your test.

It will be interesting to see how your old sensor compares to the new one if you measure the new one right

out of the package.

|

|

-

|

|

|

are you sure its gas & not oil??

|

|

-

|

|

|

Yes, I’m sure.

I’ve been given a component to check (ECT) and a sound procedure to do it.

My thanks to everyone.

|

|

-

|

|

Are there any error codes (DTCs)?

How are the ECT, O2 sensor and AMM (and associated wiring)?

|

|

-

|

|

|

No error codes Grey245.

I like the suggestions related to the coolant temperature sensor.

It was replaced during the rebuilding, but not with an OEM sensor.

Further testing this weekend will center around the ECT.

Thank you everyone!

|

|

-

|

|

|

You might check the fuel pressure at the injector rail to make sure the pressure regulator hasn’t failed, causing an over-pressure situation.

|

|

-

|

|

|

Hi Chris,

That was my thought as well.

I had the same symptoms as the OP and it was the fault of the FPR.

Without a pressure gauge, I disconnected the output line and found it completely dry. The car ran with a substitute hose connected to a container but nothing came out of it.

I assume the injectors were getting full main pump pressure which I've heard can be over 100 psi.

regards, Peter

|

|

-

|

|

|

I wouldn't disagree with any of the other suggestions made, but my 1991 945 had exactly the same symptoms as yours when the lambda sonde failed. I normally get 30+ mpg, but when it failed I was 200 miles from home, had a lumpy poor running engine and very black plugs and exhaust. Clearly running very rich, my mpg halved on the run back home which was a real struggle.

An OEM lambda sonde cured the problem immediately.

Ian F

|

|

-

|

|

|

Hi,

Unless you can suspect that the engine’s thermostat is stuck open I would also go for what

Spook says, the ECT would be the second place in line for an “electronically controlled enrichment” issue.

If the thermostat and the FPR are the only other “independent” item, short of air leakages, of which, is on the opposite end of the fueling spectrum.

I doubt the 900’s even have a cold start injector

The best way to check out the ECT system would be to troubleshoot any readings from a pin on the ECU that connects to the ECT.

There is a chart for the 240’s system that works the same way for the 900s or other vehicles using fuel management systems.

You need to back probe the appropriate pin for voltage or a resistance as both will diagnose the harness and the sensor at the same time!

I’m a 240 man so I cannot tell you which pin to back probe but should be built fairly close since it’s all Bosch.

The FAQs here are the place to research that!

I’m sure there are also threads on this subject as it’s not the first time these ECT sensors have caused a low fuel mileage issue.

14-15 MPG is totally unacceptable, as that is a hole in the gas tank!

I don’t care how much you drive around town for only short runs!

It almost like the car never warms up or worse really!

Yep, getting in there and changing the bugger will give you an experience.

If it’s an original under there, it’s like the old saying “ This is like my Maria, she gotta go!”

Not something you want to hear, when that person, is twisting on threading something in!

The first thing I do is put plastic wrap under the the radiator coolant cap and wind it on.

This helps seal off the coolant system from being able to drain and saves you from doing any draining, as it makes it air bound.

You can then Pull the sensor and very little dribble out.

It’s still best to have a the new one ready to wrestle under that manifold, but you’ll have plenty of time since you got it out and the job half done!

Good going too ya!

Phil

|

|

-

|

|

|

Thank you Machine Man.

Indeed you have a good, sensible way to track this annoying issue down.‘I’ll let you know how it goes after testing.

|

|

-

|

|

|

Dear machine man,

Hope you're well and stay so. Getting a multi-meter probe on the Engine Coolant Sensor's (ECT) pins is hard, as space is tight.

Once the connector has been separated from the sensor, corrosion-remover can be sprayed, using the thin plastic tube supplied with the aerosol can.

There's just enough room to get a wrench on the sensor: a ratcheting box wrench works best. If the user has "small" hands, there's no need to loosen the exhaust manifold bolts.

Removing the ECT does not lead to a gush of coolant, at least not if the coolant overflow tank's cap is snug. At most, a few drops should leak.

Hope this helps.

Yours faithfully,

Spook

|

|

-

|

|

|

Hi Spook!

I was only referring to do a pin check on the back of the ECU only.

I don’t know even where the ECU is on these cars, so there you go that might be as much of a bite! (:-(

I Just opening up the backside of that large connector and with using a push probe or a thin clip inserted, I get more data.

This way works to watch the changes as the engine warms up and verify that IT IS warming up to 192 F degrees. It’s a temperature that I prefer for several overall reasons.

Parts houses want their inventory to move for their reasons. I believe they ignore what is not on the shelf for the same price or profit margins.

A voltage to ground reading there will indicate a connection up to the sensor and if connected, will say what the conditions the ECU is receiving or the engine at ambient temperature.

Just a nicety to play on the engine before diving under that manifold cliff and into that jungle of wires and hoses!

I agree with you on reaching that connector too!

I have a piece of harness wire that I connect up to the sensor and take those readings!

That’s what I did until I got more experience or into educating myself.

The last part was due to getting older in more ways than one !

Phil

|

|

-

|

|

|

Dear Townshend Act,

Hope you're well. Towards the rear of the head - under the third and fourth intake manifold runners - is the engine coolant temperature sensor. This sensor "tells" the engine control module (ECM) when the engine has reached normal operating temperature. The ECM then reduces the amount of fuel supplied.

If this temperature sensor's signal is lost - failed sensor, loose (or disconnected) wiring harness connector, or a break in the wire to the ECM - excess fuel continues to be supplied. That explains most of the symptoms you report.

First, check the connector to be sure that inside the connector's plastic housing, the wires' contacts are firmly gripped by the connector's housing. I recall posts that reported the housing looked fine, but was internally broken, so the wires' metal contact - tubular in format - did not slide onto the sensors round pins. Second, make sure the connector's contacts are clean: use an aerosol corrosion-remover, e.g., Deoxit or similar. Third, inspect so much of the wiring as you can see, to find any breaks.

If all is in order with the sensor's connector housing and the wiring, then simply replace the sensor. It may not have been replaced when the engine was rebuilt. If it is the factory-original item, it is surely past the end of its service life.

Hope this helps.

Yours faithfully,

Spook

|

|

-

|

|

|

I agree with your assessment Spoke.

Makes perfect sense and I’ll be testing it this weekend.

Thank you

|

|

|

|

|