|

|

|

For more than a year now I have been trying to identify, isolate and remedy a curious condition. Car is a 1980 242 with B21F engine and K-Jet with automatic trans. The car will randomly shut off while driving. This is very intermittent. It can occur maybe twice in a week, and then not at all for 5-6 months. Independent of temperature, or how long the car has been sitting. When it cuts off, all dash warning lights come on. The oddest thing is that the car will restart immediately -- within seconds -- as if nothing was ever wrong, by simply putting the car in neutral and turning the key to start. Did not return the key to off before restarting.

While tracing possible causes have discovered some possible flaws and remedied those along the way. Not a bad thing to do on a 40+ year old car anyway.

What has been done:

New + and - battery cables, cleaned terminals and ground connections

Cleaned and tightened connections in small terminal block under hood on left fender

Replaced fuse block, cleaned and tightened all terminals. New brass fuses.

New ignition switch

New connectors an terminal for 12v connectors at coil as well a new coil

New old stock ignition control module under hood on right fender. NOS cable from module to coil

New cable from ignition control module to distributor.

Replaced distributor

New cap, rotor, plug and coil wires.

New main fuel pump, and feed pump, all terminals and connections clean and tight.

Vacuum hoses are new and tight.

What is infuriating is that once it stops, it doesn't stay stopped to allow any actual troubleshooting of the problem when it happens. Wiggling, tugging on and tapping things while car is idling in garage does not duplicate the condition. When running, it runs fantastic with strong smooth idle, and great throttle response.

Any idea what I am missing ? Thinking of calling a priest for an exorcism.

|

|

-

|

|

|

And, we're back !!!

For the past week car has been starting quicker than it has in years. Idling strong and smooth, with great response and pep while driving. And yesterday morning it cut out again with no warning. All dash lights came on. Pulled over to the side of the road. Placed in neutral, and it fired right up like a champ.

Got home, and with the car idling in the garage, I wiggled, jiggled and tugged on every wire, connector and cable associated with the ignition and fuel systems. Didn't skip a beat.

My thinking is that there is some momentary interruption possibly in the ignition that causes it to cut off, sort of like if you turn the key off and then return it to the run position. The car will be stalled, but the dash lights on. And, since the interruption is momentary, it doesn't stay around, and so is very hard to trace and identify. I'm wondering if there is something in the alternator circuit that is causing the interruption and stall ? Any possibility of the frequency valve and its associated friends ?

The journey of exploration and discovery continues !

|

|

-

|

|

|

I had a problem with a new Chevelle wagon years ago that would work

fine and suddenly quit then work for six months and quit again.

It turned out to be the heavy +12V lead to the dashboard went through

a firewall connector and that pin was mashed on assembly. I wound up

drilling through that socket pin and running a new wire that solved that problem.

Are there any connectors for the 12V wire to the dash from the battery?

If so, do a close inspection, and reassemble with a little dielectric silicone.

I've had trouble recently with bullet style connectors (round pins)

where the rubber holder for the pin disintegrates with old age.

I think you said you put a new ignition switch?

Was it OEM, or made by the elves of Guongdong?

How hard is it to give the ignition switch connector a quality

inspection that there's no loose pins or crimps?

Does your ECU come apart to inspect the PCB and look for leaky caps, etc.?

or corrosion in the connector and related ignition/fuel connectors.

Is there a connector to service at the distributor or fuel relay?

The hard part of rooting out the problem here is that you seem to have visited

everything.

Good luck, Bill

|

|

-

|

|

|

Again, thanks to all. My main challenge is that I cannot predictably make it stall. It stalls, and then immediately restarts - so whatever condition caused the stall is transient. Does not seem to be related to ambient temperature, vibration, or engine temperature.

If I could find a way to induce the stall with some reliability, Chuck's suggestion of the test lights would help isolate the problem. Another retired, experienced with this vintage Volvo mechanic friend suggested something similar with a test light visible on the dash binnacle. Problem is, if I am driving and a stall happens or starts to happen, would I really notice the light blinking off while I am watching traffic and a place to pull over ?

So, for now, still doing physical inspections and re-checks of things replaced, cleaned, tightened etc. Have basically done almost all of what everyone has suggested or surmised. Alternator is the only component in the electrical chain that has not been swapped out, so the target of a wild-ass guess.

|

|

-

|

|

|

Hi Mike,

The alternator is an unlikely culprit in your case unless it is putting

huge amounts of hash on your system that might upset your old ECU.

I'd get the cover off the ECU and look for leaking/ bulging electrolytic

caps. Send a photo of what the board looks like.

I found an 1981 Volvo 240 wiring book, TP30316-1 that covers the B21F

(Is yours a turbo?) There's multiple scenerio's with the ECU and pin 7.

The turbo has an "overload protection switch" ECU pin #7 to gnd

This is in series with the fuel relay ground.

In another circuit: there is a "pressure switch" ECU pin #7 to ground

that also is involved with the O2 sensor

In another circuit: ECU pin #7 to ground via a microswitch?

It's not obvious what actuates that switch.

Do you have the correct Volvo wiring diagram for your 1980?

That would aid troubleshooting.

Bill

|

|

-

|

|

|

Hi BIll,

Thanks for the insights. Yes I do have the proper Volvo green books with the wiring diagrams. I'll study them with your suggestions and check the car out this weekend. FYI, car is a regular 242 w/B21F -- non-turbo.

Mike

|

|

-

|

|

|

Hi Mike

What's between ECU pin #7 and ground in your car?

Do you have a micro switch there? If so, what actuates it?

If you lose this ground leg the car will quit..

Bill

|

|

-

|

|

|

Hi Mike,

Although I'm having good luck servicing my "new to me" 1993 940 with

a 1994 Volvo wiring diagram, I suppose I'll get bit any day now, like

I did using a 1981 240 book to help you.

"Close" works best with horseshoes and hand grenades,

and not so much schematics.

If you have the real McCoy Volvo book for your 1980 242:

Why don't you upload the fuel and ignition circuits for your car?

If you have it in PDF format, then share it via email.

That will help a lot.

I wish someone would step up with access to some server where we could

upload and save a collection of Volvo service documents.

It might have to be based on the moon for legal reasons.

Cheers, Bill

|

|

-

|

|

|

Hi Mike,

I’m with Art Benstein on his assessment that a connection problem to the relay or the fuel pump is very possible.

The fuel pump connectors can be some flaky as they only push on to the terminals. Corrosion is a big factors to consider as we have already have seen in the one you found.

I have seen that the posts say, you changed out the relay and presumably verified the connectors integrity.

But like Art, I couldn’t leave it alone. (:)

My 1978 uses the same tin metal ice cube relay, so, Up to and through to my year of 1984 LH system, it used them, but then, doubled down with two separate relays.

One fuel pump and one fuel injection one.

In 1985 all cars got the combined relay package with its own solder or heating up the terminals issues.

Both relays are identical in operation but I had one quit from over heating.

It had me only wondering about a intermittent this or that until it finally just went dead, while I was in town.

Fortunately for me, it died faster than your problem is doing to, or for you.

I was able to swap relays to hear the pump to begin running. No more taking a break to cool off!

So I knew it was the other relay in my hand.

I tied it shut with a shoestring and put it back in to get me home. The pump ran as soon as I turned on the key on or right away as I remember.

So I couldn’t leave it that way, unless I pulled the fuse. The ECU turns it on after seeing a distributor signal.

So check you fuse panel! Those guys are not the greatest at staying clear of corrosion or being tight between the clips.

We know you don’t have electronic injectors on the 1980 car so that leaves it as a fuel pump cutting off issue and it to be a highly suspicious item here. You see where Art can be right on!

Have you hung out under the car lately in your searches?

Those on the pump and a connector is under the rear seat.

Hidden in such a fashion as the one under the ignition coil. Same design as I remember?

Just thinking with the gang! (:-)

Phil

|

|

-

|

|

|

Thanks for taking time to ponder this Phil. To add to the picture and consider your thoughts, fuel pump relay is brand new, original Volvo. Checked/cleaned the female connectors when changing relay. As far as pump connectors, new main and feed pumps installed along with new fuel sender unit. Again, checked and cleaned all connectors. The only one I didn't do at that time was the one inside, under the seats.

Put in a new fuse panel, all cleaned, and made sure fuses (brass contact) were nice and tight in holders.

Going to once again trace and check all connections.

Also, was thinking of running a new blue wire from the fuse panel to the ballast resistor etc. in case there is something in a wiring sheath I can't see.

|

|

-

|

|

|

Hi Mike,

You are a wise-man-hunter or should I say, “Well battle hardened.”

A New panel and things proves that.

(:)

Phil

|

|

-

|

|

|

just saw new pump relay from volvo. is it a stribel brand? was it a CLASSIC volvo part from the dealer? CLASSIC is aftermarket in an oe volvo box. china's effort to maintain the 240s. if it's not stribel, i'd try a used stribel. google stribel for the logo. i've had trouble with uro and other non-oe fp relays. you probably got a prof. parts sweden in the classic box.

|

|

-

|

|

|

freq. valve-no. never.

have the alternator checked for excess ripple. too much ac voltage bleeding past the diodes MIGHT cause what you describe. the 1 time i had that happen was a turbo that would have squirrelly idle when anything electric was turned on, headlight, blower, anything and the idle would up and down, etc until whatever was turned off. excess ac voltage screwed with the idle brain and caused it to go haywire. i think your problem and the alternator is a long shot because that ignition was used from 76 until the 240 turbos in 85 and haven't heard off the car cutting off.

i would put test lights at every point i can on that blue wire and watch them as it stalls. yeah, i know, about 6 or 7 needed. ign sw, fuse box, resistor, everywhere. good luck, chuck.

|

|

-

|

|

|

Aww, Mike,

Alternator, no. Frequency valve and relay, again, no. Don't associate the warning lights coming on with anything but the fact that the motor stopped turning the alternator.

My bet hasn't changed. Fuel relay and socket. But that's just a slightly educated guess. I think Chuck brought this up first.

Edit: OK so the relay is new...

I've heard the pickup coil in the distributor is known to develop an open circuit affected by heat under the hood, but I can't imagine it fixing itself so quickly. Problem is, I have no experience with that particular issue.

--

Art Benstein near Baltimore

They say we need to stay six feet apart but I just can’t fathom that.

|

|

-

|

|

|

Hi ART,

I did suspect the pickup coil n the distributor, but this has happened with two different NOS distributors.

Mike

|

|

-

|

|

|

Mike, it sure seems like you've covered every replaceable part, and to an extent that parts most of us don't think of as a replaceable parts -- the wiring and even the fuse panel.

Chuck has the advice I would follow when he suggests putting test lights on the circuitry. I resorted to this method in the late 90's on a Mitsubishi that would have my daughter stalled on the side of the road, only to be re-started just before the tow truck arrived. It was an array of red, green, and yellow LEDs wired to monitor the voltage and current to the fuel pump, voltage to the ignition coil, and from the ignition switch.

And sure enough, it was silly of me to think anyone would have the presence of mind to note the LEDs during the moments needed to get the vehicle to a safe spot, but her symptom didn't include the immediate re-start ability. The lights indicated voltage at the fuel pump relay coil, but no fuel pump current and no switched voltage to the fuel pump. I remember replacing the fuel pump relay. Probably something an experienced mechanic or technician would have done at the first sign.

I've been waiting for just this kind of scenario to occur in our Volvo fleet, with a datalogger, to be made from this LabJack and an old raspberry pi buried on the electrical project bench, but so far the thought alone seems to keep the gremlins away. Sorry.

--

Art Benstein near Baltimore

The sole purpose of a child’s middle name, is so he can tell when he’s really in trouble.

|

|

-

|

|

|

Latest update. Based upon the helpful and much appreciated insights and guidance from those in this thread, I have gone back adn re-checked what I had done before, and made sure I had also considered/addressed other suggestions made by fellow Bricksters here. This morning, the last thing I needed to do was trace every inch of eh blue wire that comes from the fuse block/ignition switch to the plastic connector under the hood where it divides into two wires - one to the ballast resistor and the other to the ignition amplifier. This had been the only connector I had not previously removed, repaired or replaced.

It took some effort to get the two halves of the plastic connector apart. When they separated, my son who was working with me, noted that "shovelfuls" corrosion and particulates came tumbling out. Probably had not been apart in 20+ years. Another clear issue to be remedied and a possible cause of the recurring random problem. I scraped, brushed, and cleaned the connectors with electric contact cleaner and reassembled. The two halves definitely slid on easier, but still tight, than they came apart. Car now starts, runs and idles beautifully. We'll see how things work out over the next 2 weeks - 6 months, the random intervals at which the problem had appeared before.

NOTE to SELF (and others): Every 30-40 years and/or 300,000 miles, check, clean, or replace all electrical contacts and connectors in the ignition circuits.

|

|

-

|

|

|

Hi there,

Glad to hear you found something that seems very worthy of the hunting.

I hope you enjoyed your time away in Germany.

Looks like it must have helped you, to be able to find the Sauerkrauts in a car with a few German parts.

AKA … Gremlins to troubleshooters. (:-).

Their parents, Mother Nature and Father Time, have no country boundaries.

Where is that connector exactly?

It’s under the hood, you say?

I know of a ballast resistor on my 1978 GT under a shock tower.

Past that I jump in years to a 1984 with its, new then, LH system.

I believe the ignition coils might be different by then too.

Phil

|

|

-

|

|

|

Hi Phil,

The black plastic connector on my 1980 is where the blue wire comes out of a wiring harness sheath that runs along the cowl under the hood,just about under the wiper motor, near the coil. The single blue wire that comes out of the wiring harness sheath, joins to a connector from which two blue wires come out. One of those blue wires goes to the ballast resistor, and the other goes into the wiring harness that connects to the ignition amplifier.

This is one more plausible and likely "flaw" that I have uncovered in doing the tracing and troubleshooting. It is also, as far as I can tell, the only connector, junction point or component that had not been checked, removed or replaced. Hopefully now all has been sorted and the gremlins expelled.

|

|

-

|

|

|

Hi Mike and Art,

Thanks for the prompt response back. I went and took a look under the hood of my 1978 GT. Sure enough it was there along with the other crusty varmints on this age of car.

I checked that connector once with an issue of hard to restart.

But that turned out to be a frequency valve and oxygen sensor relay that went toast with some water entry and it’s corrosion ability.

Too much Moisture can make for a lousy slice of toast too. (:-)

Wire number three?

I never thought as the little back box it goes to as an “ignition amplifier.” It replaced mechanical points and a needed condenser.

I went with thinking of it as an ICU, mentally. (:)

Not an “intensive care unit of a physic hospital.

Thanks guys but no thanks.(:-)

I related to only, as an earlier made, over sized, ICU.

These cars had fancy ECU boxes with the all newer jet-tronic goodies helping to bring us the new age.

The carburetor was being eyeballed as a sophisticated throated bucket of gas with bleeding drip holes in it.

Then again the term breaker-less ignition systems fell to the waysides of hype very quickly.

A fuel injection rage was rising up fast.

Todays ICUs have shrunk into a size of pack of cigarettes.

I agree that Art’s pictures are always very helpful and clearly taken well in many ways, by all!

His Shots are a lot better than what I get on my cell phone camera.

I have tried using the brighter or more intense LED lights in tight places but all I get is deeper contrasted shadows.

The light from them just doesn’t bounce and reflect about like incandescent or fluorescence bulbs use to do, IMHO.

What I see is, My old eyes are doing better at seeing into those shadows.

The camera loses it.

Is it the pixel count or it’s sensitivity?

A single lens compromise or limitations?

Maybe it’s the lack of aperture controls for depth?

But then, my phone old. It’s is a six series. Their passing 12 or 13 now.

My wire Colors bleed away and there’s Nothing panoramic about it, let me tell ya!

Hey Art do you keep that 1979 in that great of shape under the hood, is it the photo, taken way earlier, that’s keeping it that way?

Either way your pictures sure do keep me jealous!

My 1978 needs another total repaint on the outside because the first one lost its clear coat.

My $500 DuPont Imron paint job, in the eighties, also gave up over this many years. Now the paint, alone, costs that much. (:-(

The car also needs a rejuvenating experience under the hood too.

It’s turned into my beater for now, as I use it for few hundred miles a year. Just close around and in town driving.

Except the front seats were reupholstered @$220 apiece at least 20+ years ago but he did a great job with better material than nearly matched. Still got those red stripes too.

Well, enough for tonight.

You guys are on your own with this long a post.

You’re probably late going someplace? (:-)

Phil

|

|

-

-

|

|

|

That's the guy. Easy to overlook in the investigative process. Thanks for the great pics, Art.

Mike

|

|

-

|

|

|

ol' dopey me....glad you found it.

|

|

-

|

|

|

Well, we will know with a bit more certainty in a couple of weeks or several months !

Again, thanks to all for sharing in this diagnostic journey.

|

|

-

|

|

|

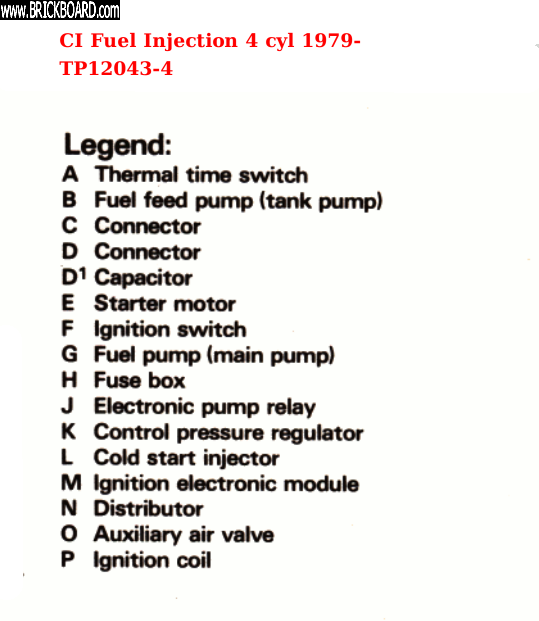

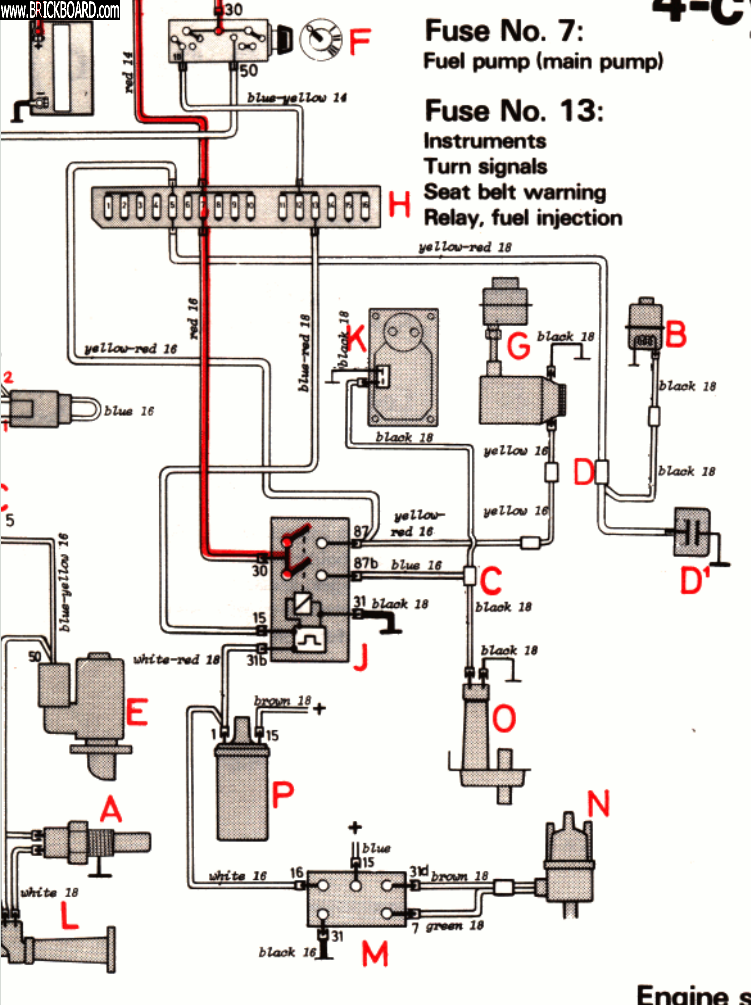

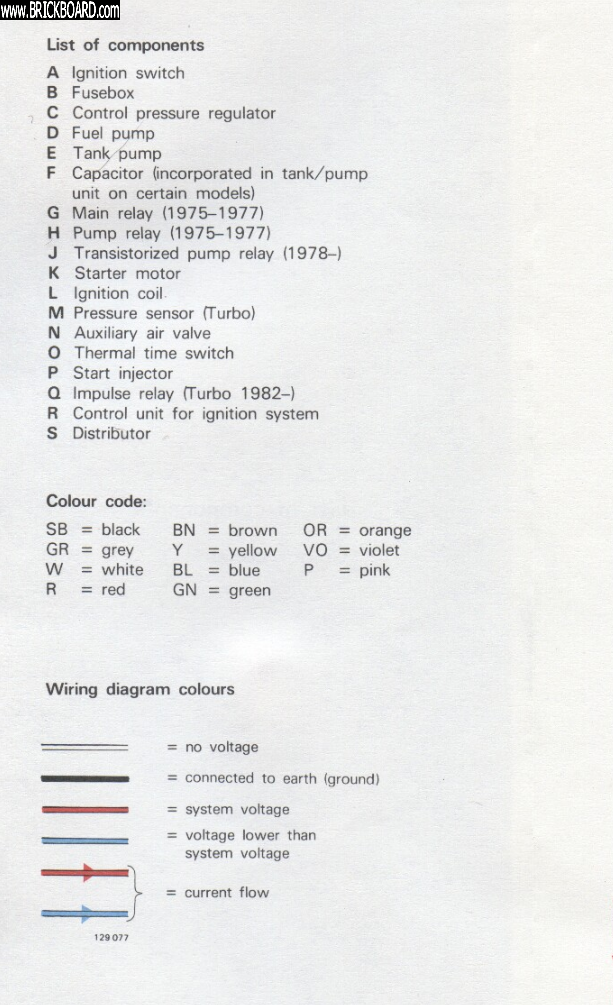

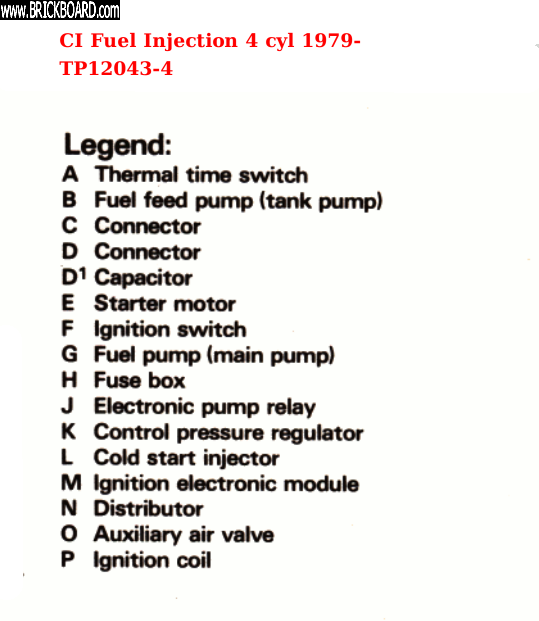

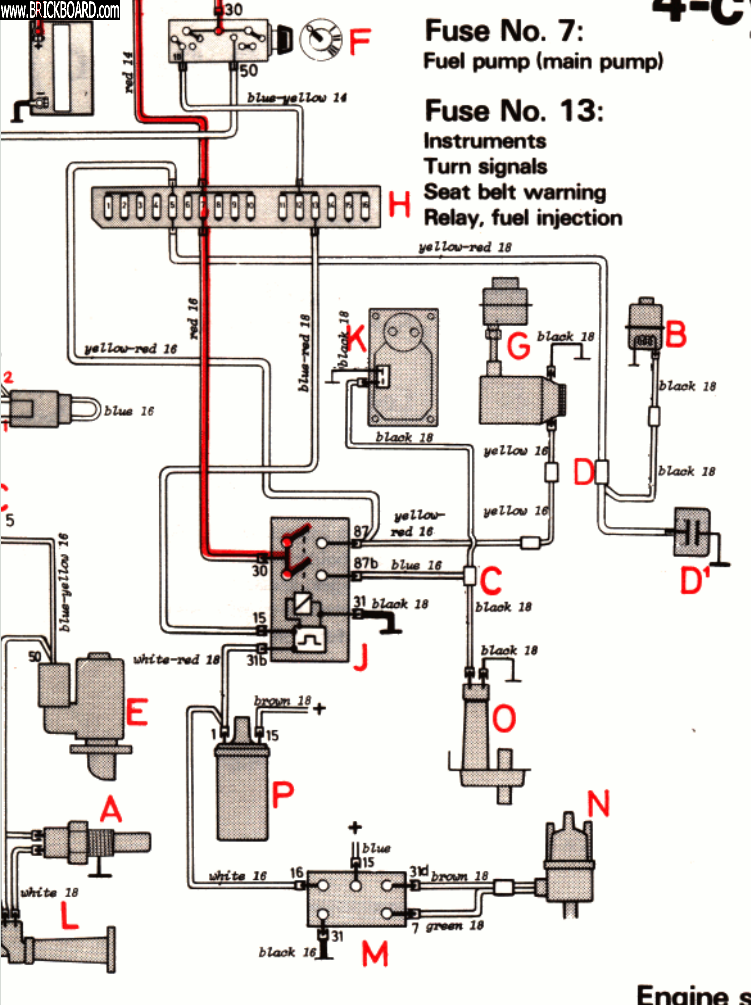

I goofed and put up the wrong legend for the fuel schematic.

Here it is from a newer CI Fuel injection Greenbook TP 12043-4.

Bill

|

|

-

|

|

|

Hello Michael.

Well I can give you two places to look as I have had a 1978 GT with a K- Jet since then and had this happen to me for a little while. It took patience to find one of my two possibilities.

The first one I thought it was either the ballast resistor located underneath the left shock tower. It had rusted terminals. I cleaned them as it would sometimes fail to start right away. It didn’t fix anything.

I later change out the black box that’s part of the ignition system and it didn’t really improve anything.

As like in your case, it takes a long time to get it to happen.

It would be occasionally hard to start after running but was so random it just bugs you.

Then one day it hesitated to start when cranking.

I eventually got it to start but it ran rough and was barely drivable and would stop dead.

During its running moments, I did noticed, that I no longer heard the frequency valve buzzing!

Very important to have it do that.

I think … It will buzz for a second or so after dying or a shut down.

Listen for it!

I tapped around on it and other things and drove it home.

So I investigated every little guy connected to that thing in diagrams.

It turns out that there is a relay on the left fender that turns that frequency valve on by connecting it to the ECU.

The frequency valve does what the AMM does today, controls mixture mechanically.

Sort of a injector, that doesn’t inject but modulates.

Part of the Lambda system and O2 sensor out of the ECU.

The relay had gotten water inside it and was nasty!

I replaced it and I have not had anymore problems with that issue for many years now.

The relay is silver metal box about one inch square and is a common relay I think. Cannot remember, at the moment, if it’s a single or two circuit relay but it’s common on these late seventies and early eighties cars.

Study the diagrams from the frequency valve over to it. The Hayes and Bentley’s diagrams are barely readable with a magnifying glass.

Luckily I have the Volvo Green Books for this car. The illustrated pages are the best thing about them, but trust me, they were overly expensive and somewhat extravagant with those green binders.

I bought them soon after buying the car for $8,000 and with 8,000 miles from the dealers service manager. He recommended ordering books. That was $300.

It was my first Volvo and foreign to me, like everything else when you’re about 25 years old, then!

I would say it paid off, that one time.

With today’s diagnosis prices, I broke even.

Check the connector for corrosion or even Exchange that relay out.

They don’t last forever.

Phil

|

|

-

|

|

|

Thanks guys. New fuel pump relay arrived today and is going in now.

Appreciate your mention of the freq valve and its relay, Phil. Car always starts quickly and easily. No probs there. And the freq valve does indeed buzz steadily even when being tapped etc. However, that relay is old, and the electrical connector at the freq valve has not been touched in a long while. Time to clean those up and replace if necessary.

And YES, the Volvo Green Books are wonderful. Well worth my investment in them 42 years ago !

Thanks again.

|

|

-

|

|

|

you also didn't say new coil. i owned at the same time 3 242s, 76, 78 and an 80 gt. also worked on a lot of them 20 yrs ago. lost a coil on my 76-but it wouldn't start until cooled. lost a dist pickup on a customers 80 or 81. again-cooled restart. numerous fuel pump relays, the fuse box where the blue wire leaves for the ballast resistor, the resistor itself,. the wire from the ignition to the dist, etc. the fuel pump relay came be bypassed for testing with a jumper wire-same for the lambda relay, but i doubt that's the stalling problem. the freq. valve adjusts the control pressure at the fuel dist in minor movements. if the car stalls when freq valve quits, i'd look for another problem in fuel pressures.

like i said, might have to wait for a complete failure.

|

|

-

|

|

|

Yes, new coil and ballast resistor. Checked, cleaned and made sure blue wire connections were all tight between fuse box and ballast resistor and coil. What is really, really curious is that it restarts immediately. No waiting for anything to cool or reset. This is what makes it so hard to trace and diagnose.

I'm going to double/triple check all vacuum hoses, including the big rubber bellows between the throttle body and air/fuel control unit.

Do you think anything internal to the fuel distributor ? Like I said, it starts fine and runs fine -- until it stops -- and then can be restarted immediately.

|

|

-

|

|

|

a vacuum leak is not your problem, neither is the fuel dist. all the different kjet cars i worked on, volvo bmw, mb, vw, ferrari, etc., in 25 yrs or so, i replaced 1 fuel dist because the fuel tank was full of water and rusted everything. and never had a fuel dist cause a stall.

there is no wire in the engine harness that can make the car stall, so forget that. it is electrical but not there.

does it have a tach? what does that do when it stalls? goes dead, it's ignition. flutters while stalling, it's fuel.

|

|

-

|

|

|

Tach goes dead when it stalls, and all dash warning lights come on. My initial thought was ignition as well, but have not been able to isolate the culprit. Despite checking and replacing just about every ignition component, problem persists.

Appreciate all the input. At least gives a good sanity check and checklist of things to watch for.

Mike

|

|

-

-

|

|

|

That's an interesting link to the write-up on the tachymetric relays used in the various Bosch Jetronic systems.

He notes the causes of relay failures in these systems, more or less in order of likelihood:

Loose or melted soldered joints, oxidized outer relay contact terminals, broken relay coil winding wire, burnt diode or resistor, sticky/oxidized main relay energizing contact points.

As for capicitor D1 shown for the in-tank pump, I'm not familiar with it, but if you were to look at the following page in that Volvo manual you would see it shown as a separate device, a smallish rectangular cube with a screw mount tab, almost like a power transistor, with pigtails and a bullet wiring connector on the incoming black wire, so presumably it's not far from the pump. Doesn't look like something that would live in-tank. The wiring schematic suggests it lives externally between the tank fuel assembly electrical connector (yellow-red wire) and a nearby chassis ground point. I'm guessing it might be there to help cleanup electrical noise for the rear fender mounted radio antennas. I don't see it on later K-Jet system diagrams. Somebody like Art should know.

On Art's topic of the Volvo relays being adequate for the job, I noted the Valeo relay pictured in that same writeup. It's used by VW and others, while Volvo relays are typically Bosch. I looked it up and it's rated as 30A while Volvo often uses only 16A-25A rated relays in our LH systems. That lends credence to my arguments that Volvo didn't go overboard on a heavy duty relay and why I prefer the 30A Striebels carried by a number of our Volvo aftermarket suppliers. A 16A rating might be good enough for a K-Jet system where they just have to handle the main and in-tank pumps with a total current draw in the order of 6.5A-10A (depending on pump wear). However, by the time you get to the later LH 2.2 and 2.4 systems where they are used as system relays, in addition to the pumps now drawing 8A-12A (6.5A main +1.5A pre-pump +wear load), they have other currents going through the relay on tab 30 such as injectors, IAC valve, AMM and ECU. I once heard a shop say they've seen close to 14A on a badly worn main pump alone. Those system relays are on a 25A fuse, but from what I can tell many of the Volvo relays are only rated for 20A-25A (it's not always indicated). Fuses should blow long before a relay is pushed anywhere near its limit. Between oxidation and continual thermal expansion/contraction resulting in weaker contact grips and failing solder joints, plus the odd relay removal, it no longer surprises me when I see relay tab 30 showing heat marks, bad solder joints and deformed relay sockets. The 700/900 headlamp K relays are a similar problem area (had one almost too hot to touch just the other day, thankfully the relay tray socket hasn't deformed yet).

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

-

|

|

|

Hi Dave,

So many subjects.

That D1 cap at the tank certainly is to get rid of pump motor hash that would

raise heck with the AM and Ham mobile, and possibly an aging ECU with geriatric electrolytic caps.

Does the 1980 240 ECU have any electrolyitics?

Can you get the cover off the ECU to check and maybe replace?

"I once heard a shop say they've seen close to 14A on a badly worn main pump alone."

Do fuel pumps draw more and more current before they fail?

Perhaps measuring current flow for the pump at the fuse would be a simple health check.

Yes, the fuse should blow before the relay socket starts melting.

This is good for a thread of it's own.

Hot K relays? Which relay and car? 940?

If it's hot, then something needs fixing or replacing.

Please start a new post about this.

Cheers, Bill

|

|

-

|

|

|

Hi Bill,

There's a lot of electrical mythology getting passed around.

"Does the 1980 240 ECU have any electrolyitics?"

ECU? This is kjet lambda. The fuel controller fine tunes the mixture of fuel and air via the frequency valve. Sure it has capacitors, but none that would cause the random stall we're looking at. Haven't tried it but I bet you could unplug the ECU without stalling the motor.

The guts: http://cleanflametrap.com/kjetController.htm

"If it's hot, then something needs fixing or replacing."

Check what is making it hot. Chances are it isn't the open frame relay contacts -- those that determine its current rating. Keep in mind each relay coil (there are two in the later LH fuel relays) dissipates >2 watts bottled up in the package. That's without any current at all being switched. I've seen advice on here to drill holes!

--

Art Benstein near Baltimore

Behind every successful man is his woman. Behind the fall of a successful man is usually another woman.

|

|

-

-

|

|

|

Hi Bill,

"It's obvious that some problem relays are hotter than others when they fry the fuse block. "

This is a hard myth to dispel. The burned socket plastic, something the 7/9 ashtray fuse panel famously displays, but exists in those sockets hidden in 240s as well, is not caused by hot relays, but a hot junction between the relay terminals and the wiring harness. The cause is contact resistance in the aging wiring raised with moisture and oxidation. If you were to replace the relay AND the socket, the problem would be resolved until age and moisture catches up with the replacement parts.

"Did you run that test with more than one relay "

That was more of a demo than a test, inspired by all the posts complaining about "hot relays" which are normally hot in operation regardless of the current they are switching. The coil generates the heat. It doesn't vary that much among these automotive relays. They all have similar current consumption. Put a two-watt lamp in a little box and see how warm it gets after an hour. Yes it feels hot to the touch, but well within safe limits for electrical components in the automotive environment. Same heat was produced by them when the car was new.

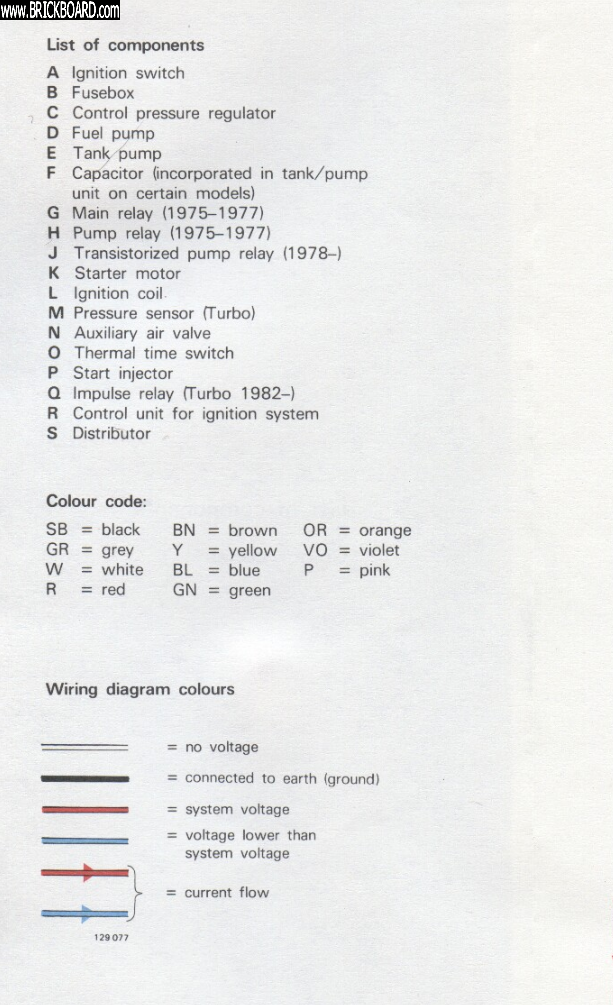

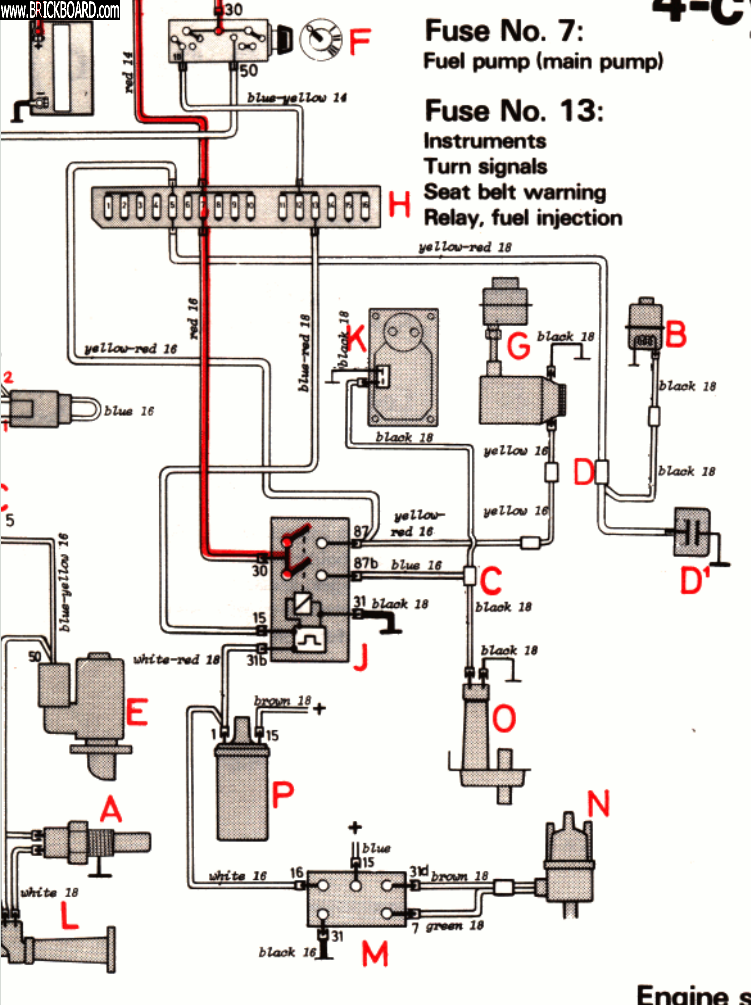

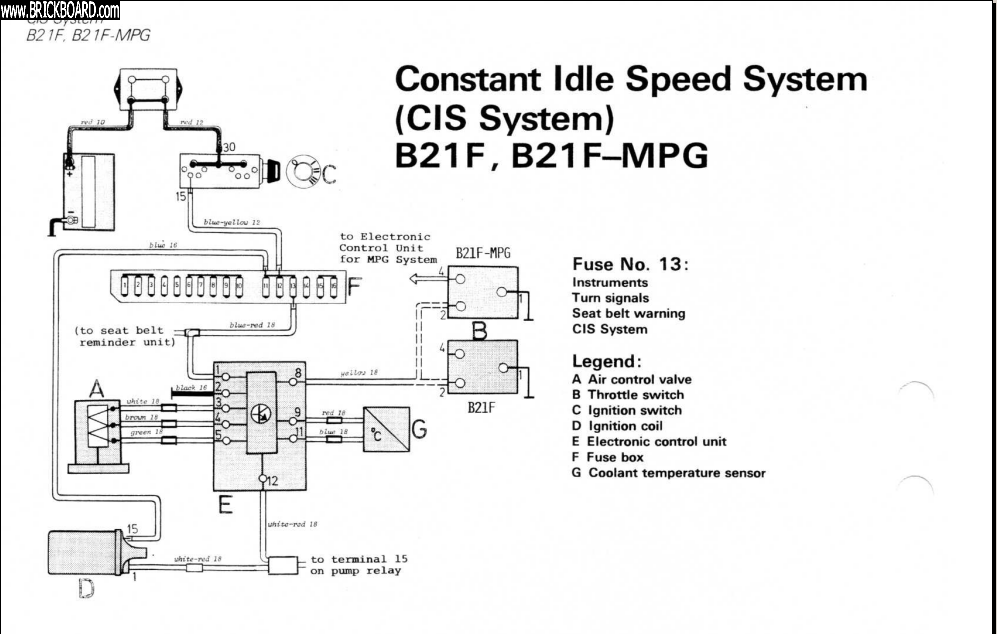

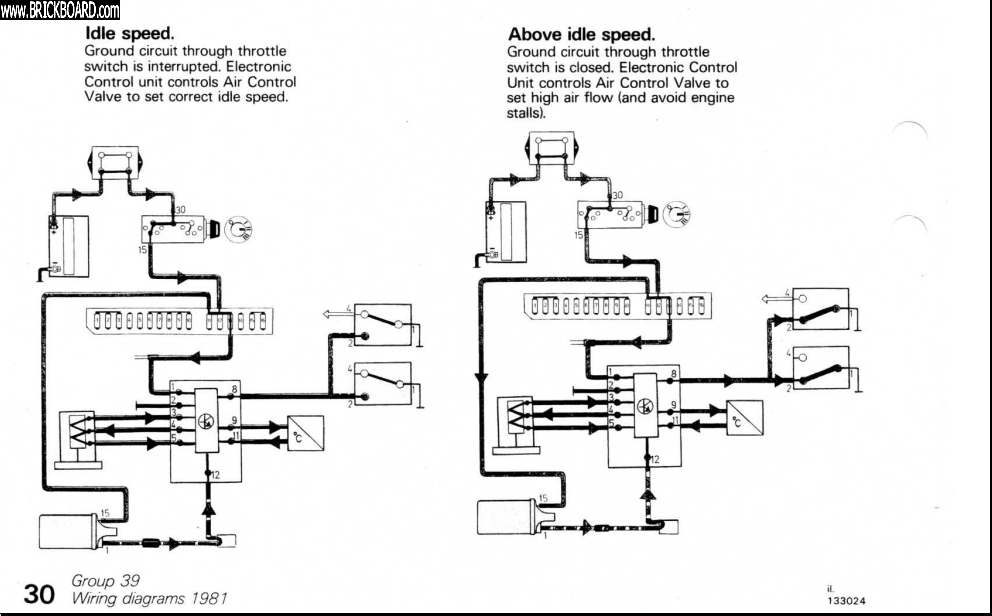

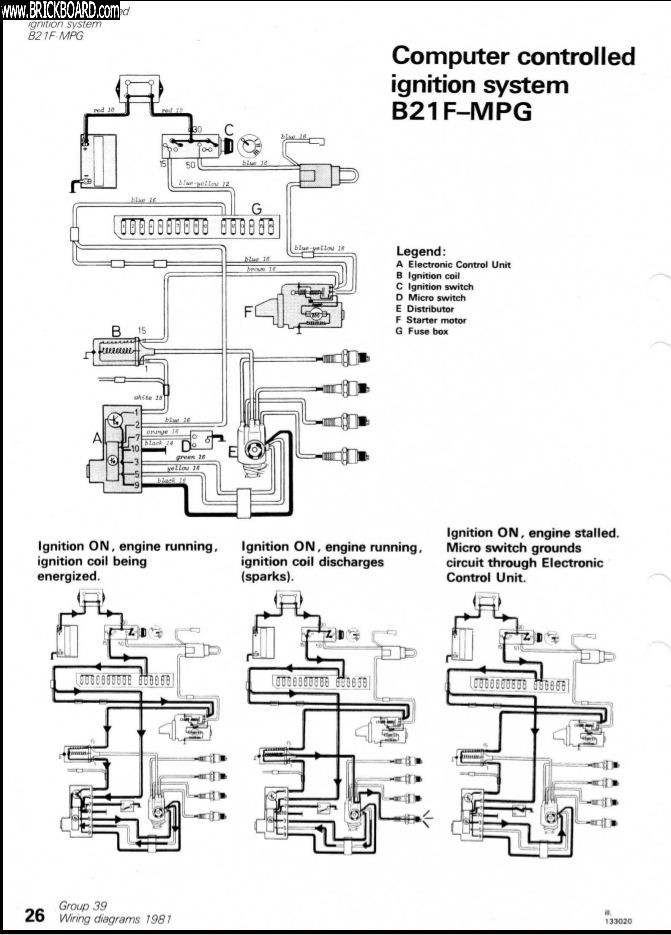

The drawings you posted are for the constant idle system, debuted in '81, and the Volvo/Chrysler "computerized" ignition, also new for '81. Edit: Later look I see you found the lambda controller map. The pin 7 (which I think I labeled as 6 in my reverse drawing) in the lambda controller is for enrichment during warm-up, and via a throttle switch, during step-on-it accel.

Finding the correct drawings for these cars is a constant challenge, isn't it? Much easier for these 240s than the 7/9 series don't you think?

--

Art Benstein near Baltimore

Hospitality: making your guests feel like they’re at home, even if you wish they were.

|

|

-

|

|

|

Thanks so, so, much guys. I am currently traveling in Germany, but will do a thorough check when I get home in a couple of days. Will have a very good retired Volvo tech work with me as a second set of eyes. He has suspected very similar things, but you guys have provided such a great check list for us to go through.

|

|

-

|

|

|

understand the tach is wired to the coil, not the plugs, etc. and when i say ignition, i mean the electrical supply to the ignition. dopey me, i'd look at every inch of the blue wire from the ignition switch to the coil and ign ecu. i can't see under your hood, the light here sucks.

|

|

-

|

|

|

Will do, will trace and inspect the blue. Even in the dark, I trust your experience and expertise.

Mike

|

|

-

|

|

|

I'll put in my prediction that fuel relay replacement will do the trick.

My opinion about watching the tach to guess fuel or spark: If the fuel pump quits, because power is interrupted, as would happen if the fuel relay caused it, you won't see any hesitation on the tach. More to the point, you won't be looking at the tach until the seat of your pants tells you to look for a pull-off right now, and all the red lights come on.

And those lights don't come on until the engine stops turning and the alternator stops with it. All within a half second. Try it. Simulate by lifting fuse 7 while the car is running. See how fast the tach drops and the warning lights come on. Put some load on the engine (in drive if an auto with the brake on) and see how fast stopping the fuel pump stops the motor.

Back to my prediction. I just got done repairing some old k-jet relays I collected back when these cars still populated the pnp yards. I think they may have been the reason they were in the junk yards. One was beyond re-soldering, another the victim of some quick-fixer jamming the relay contacts closed.

Anyhow, it seems most have a burn mark on the bottom either at 30 or 87, that made many techs replace the relay but miss the relay socket. So many even believe the relay is somehow at fault for not being rated for enough current. Not true. The relay contacts are rated 3x the main pump current. But the socket's relaxed grip on the relay terminal was the point of high resistance and cause of the heat. The problem is the relay socket and the moisture that follows the wiring into it.

On the other hand, in my 79, I had a trouble 20 years ago where the ignition would fail. The eventual fix was as noted above, the terminals connecting the ballast resistor. Restart and die. You've covered this. The sudden stall, even at speed, can be a connector anywhere in the fuel or ignition -- even the fuse contacts themselves.

If you see any evidence of overheating on your old relay, pull the socket apart and attend to the female spade terminals. Check the crimps. Maybe add your favorite moisture excluding grease. Even if you don't see the overheating evidence on the outside, have a look inside.

--

Art Benstein near Baltimore

SUCCESS:

At age 4 success is . . . not peeing in your pants.

At age 12 success is . . . having friends.

At age 16 success is . . . having a drivers license.

At age 20 success is . . . going all the way.

At age 35 success is . . . having money.

At age 50 success is . . . having money.

At age 60 success is . . . going all the way.

At age 70 success is . . . having a drivers license.

At age 75 success is . . . having friends.

At age 80 success is . . . not peeing in your pants.

|

|

-

|

|

|

Hi Art,

I agree about funky fuel relays and cheesy sockets causing Volvo's to head

to the boneyards. Burned relays and fuseblocks have to be the result of

resistive socket connections.

Do you know the source/manufacturer/part # for the crimp-on pins for the relay sockets?

They must get loosened by too many crude relay extractions.

There should be a tool to pull the relays straight up without rocking them.

You can try to crunch the pins back so they are tight, but new is better.

Cheers, Bill

|

|

-

|

|

|

Hi Bill,

Volvo does list all the parts they used to build harnesses, but it is a research project to come up with something to repair one connector. Examples here:

Here in the US, we have a fellow 240 enthusiast who simplified this all for us: Dave Barton. His web pages are truly amazing: https://www.prancingmoose.com/blackvinyl.html

Cheers to you too!

--

Art Benstein near Baltimore

"The things we learn from our children we retain longer than they do. Example: lighting a match to let the sulphur cover and de-personalize the odor of poop." -Philip Clarence

|

|

-

|

|

|

Hi Art,

Thanks for the nice response.

I had an OBD socket pin fail because the rubber or whatever spacer that holds the pin deteriorated.

see here: https://www.brickboard.com/RWD/volvo/1685063/940/960/980/V90/S90/source_found_obd_port_pins.html

I could have done better at Dave Barton's site as I see what look like the right

pigtail assemblies there. What a nice site as you say!

The 700/900 main fuse-blocks also have the bulk of the relays, and the female sockets are filled with harness wires with crimp-on spade lugs with a little latch that snaps into the sockets. I'm guessing that careless removal of the relays can spread open the pins of the spade lugs and lead to toasted pins that are carrying high current. It's easy to solder a male spade lug the same dimensions as the relay pins to a stiff hunk of #14 or #12 ga copper to test your relay socket for loose pins and know which pins need to be removed and tightened.

I'm assuming the photo's of fuel relays with toasted pins are the result of

loose male spade lugs. Arcing wont help the ECU functions.

Do old fuel pumps draw higher and higher current before they crap out to cause these headaches? If so, people can easily measure their fuel pump current draw

to get a sense of it's health.

I'd still like to find the female crimp-on spade lug with latch that Volvo uses for 700/900 relay sockets.

Keep cool, Bill

|

|

-

|

|

|

I assume your engine harness is not in the 1981 - 1986(about) group that were dis-integrating under its heat shrink cover. If the 1980 production year was bad I would closely look.

|

|

-

|

|

|

Replaced the engine harness several years ago with the upgraded one. But always worth an updated look to check condition.

|

|

-

|

|

|

you don't mention new fuel pump relay.

yes, it's gotta get worse, i.e. won't start asap before you find it. good luck, chuck.

|

|

|

|

|