|

Art's pic brought back vivid memories of having problems with that oil pessure sensor wire in mid/late-80's 240s with the crumbling wire insulation that plagued those 240 years. Yours has better insulation, but that exposed single smaller gauge wire still lives in a harsh environment.

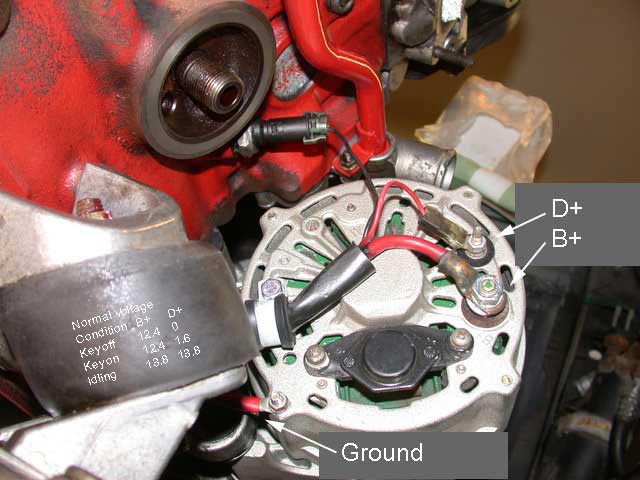

That branch of the engine harness goes under the block at the front, exposed to engine heat and oil grunge. That oil sensor wire would often crumble inside the harness at the bottom and eventually short to an exposed section of the D+ alt wire that had started to crumble. The easy fix was to cut it off at both ends, so no more short, and run a new wire outside the harness to the sensor. The main alt wire never crumbled. The D+ wire could crumble all it wanted inside and there would be nothing to short to. Some people would split the harness open and try rebuilding that section, which often wouldn't last. Many would get an entire new harness. It was so common that there were a number of aftermarket sources

It also wasn't uncommon to see the whole exposed section now bare, corroded, brittle copper, hanging onto the connector, probably more like what happened to yours.

You can grab the other end of that wire at a connector block over on the far side of the firewall. I'd cut it off there and run a new wire across the firewall, down the fender and across over to the sensor. I used black oven wire designed for high heat. As I vaguely recall, I didn't try to splice at the old connector, but instead crimped up a new connector from an oven grad nickle crimp terminal and heatshrinked it (aluminum crimp terminals likely wouldn't last long there). I did two 240s and never had another problem. Also, I could only get black oven wire in a 50 ft spool from a wholesaler, so plently left over for trailer wiring jobs. Probably still got 20 ft somewhere in the bottom of a box. I've recently seen oven wire sold by the foot in the big box stores.

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|