|

Hiya Uncle Old Duke!!!

Happy Christmas and hope all's aces for you and everybody!!!

You and Uncle Art sure know your Maytag appliances!!!

Please forgive my sloe (gin) reply.

Do not know Moe Forker. Same as Uncle Moe you mention occasionally?

Art can pull the Maytag washer agitator spindle using the same hardware to lift and hold the engine like when replacing 240 motor mounts!

You used to be able to get a seal kit from Sears for Craftsman jacks they sold, so I was told.

As for your 1973 Craftsman floor jack, and you have another leaky floor jack (?), if no go from the manufacturer, you can find other resources.

You may find a store that sells industrial o-rings. The o-ring carrying groove in the cylinder bore and / or on the piston can be measured and a learned person can suggest an o-ring made of a material useful for the application. The bore and piston surfaces should be somehow acceptable.

Else, I'm unsure of disassembly. I found many videos on You Tube. What Torin documentation I found was this site (copy and paste) and all of it is new and no service doc:

https://www.hcrcnow.com/drawings/torin-big-red

An article on rebuilding a floor jack, with a link to a supplier of kits:

Rebuilding a Hydraulic Floor Jack

https://www.instructables.com/Rebuilding-a-Hydraulic-Floor-Jack/

The article mentions Backhawk Hydraulic Parts to buy a seal and rebuild kit for the jack. Yet the jack in the article is a new or recent Harbor Freight?

https://www.blackhawkparts.com/

May be other hydraulic parts vendors for floor jacks?

I bought a used Craftsman jack in 2008 or so. I had a heavy duty jack that was orange or red from the 1970s yet that got left behind in Oregon. Wah. Boo. Hoo.

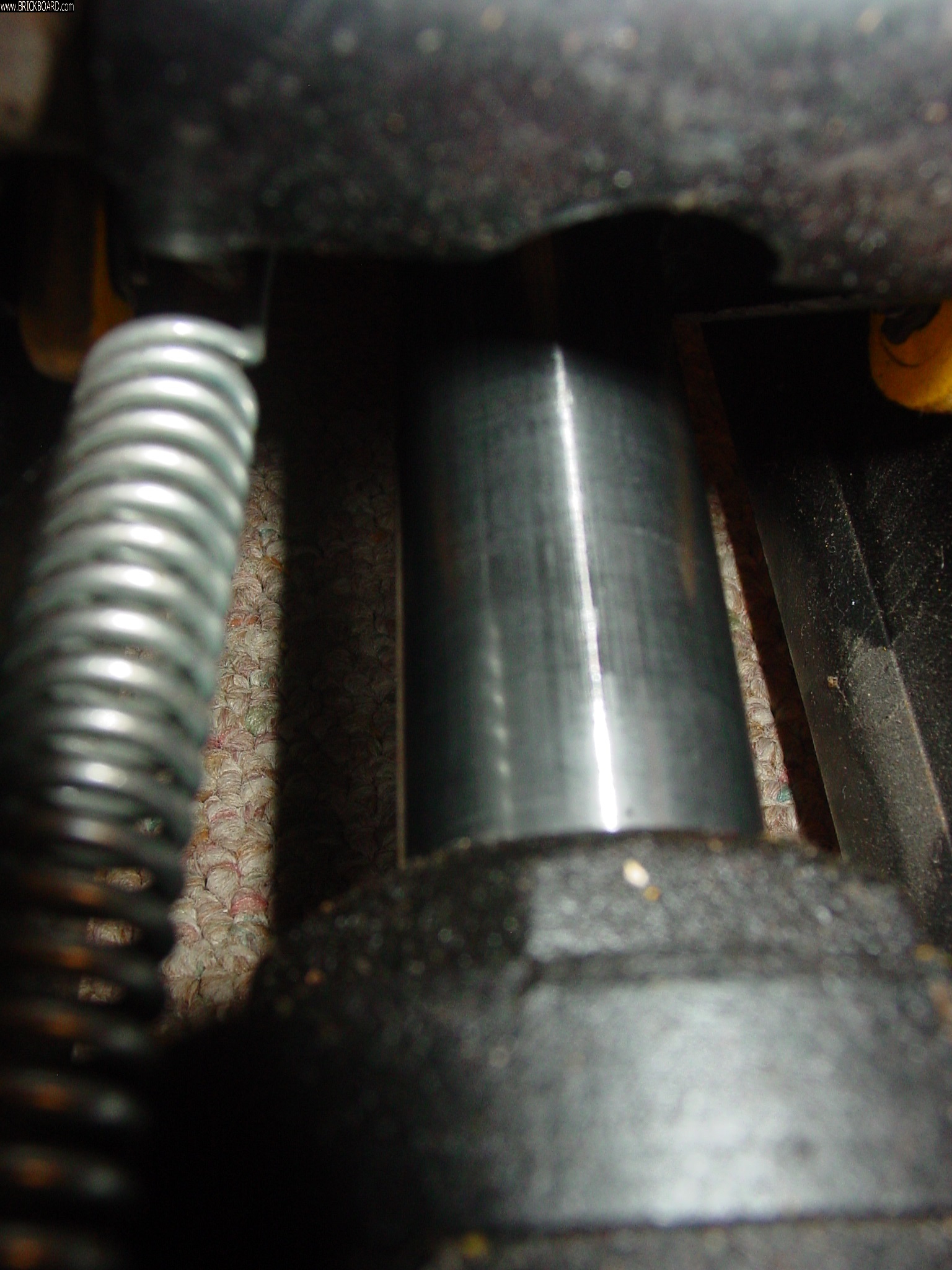

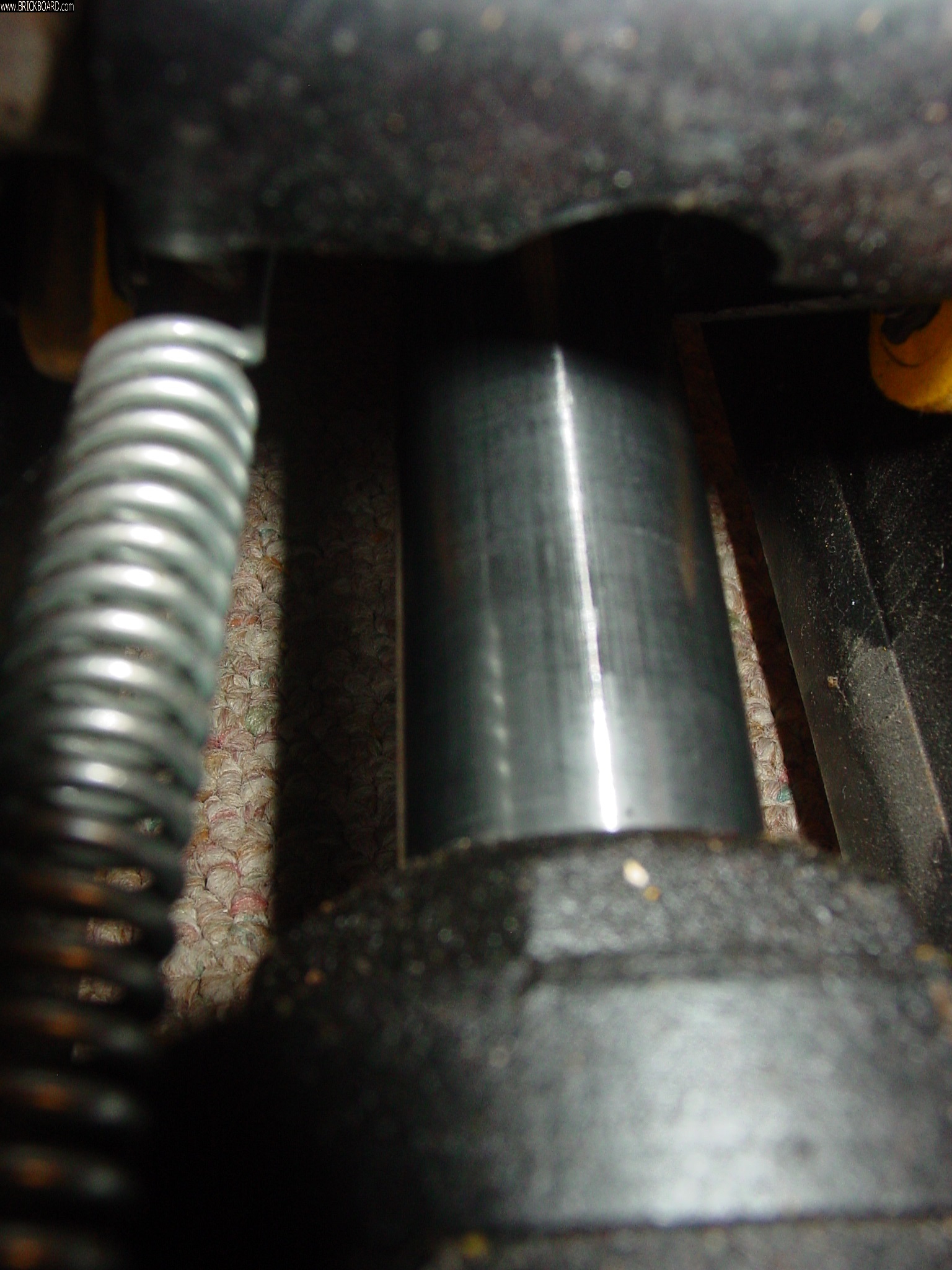

My trolley / floor jack bought used a decade ago.

It would leak more so at rest than in use. Like a clogged PCV and an old back of the overhead camshaft seal leaking. You can get hydraulic jack fluid yet I had bottles of Ford "Type F" to refill it.

I imagine different floor and bottle nose jack makes and models use different hydraulic fluids.

The fluid would drip out at the bottom of the piston bore when in the relaxed or fully lowered position. I close the fluid release to lower the lift after it filly lowers.

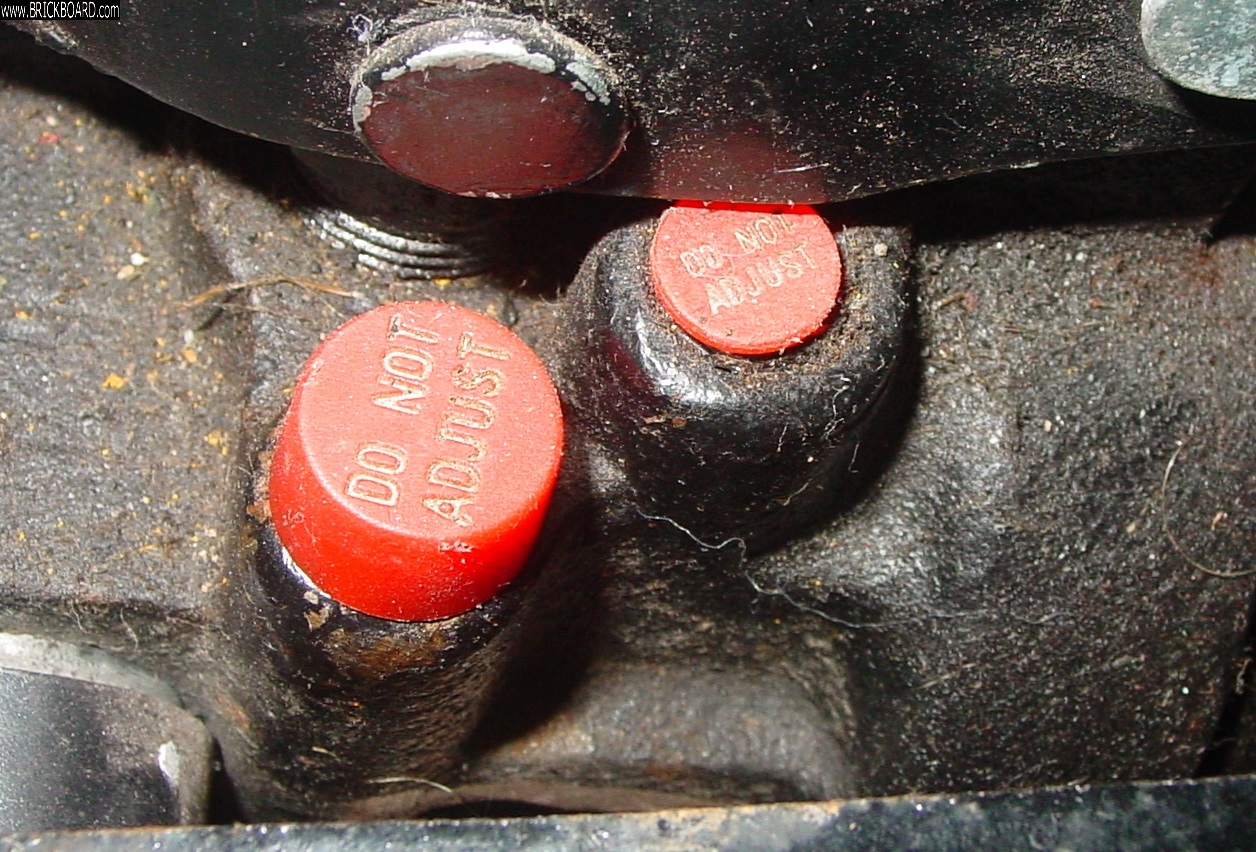

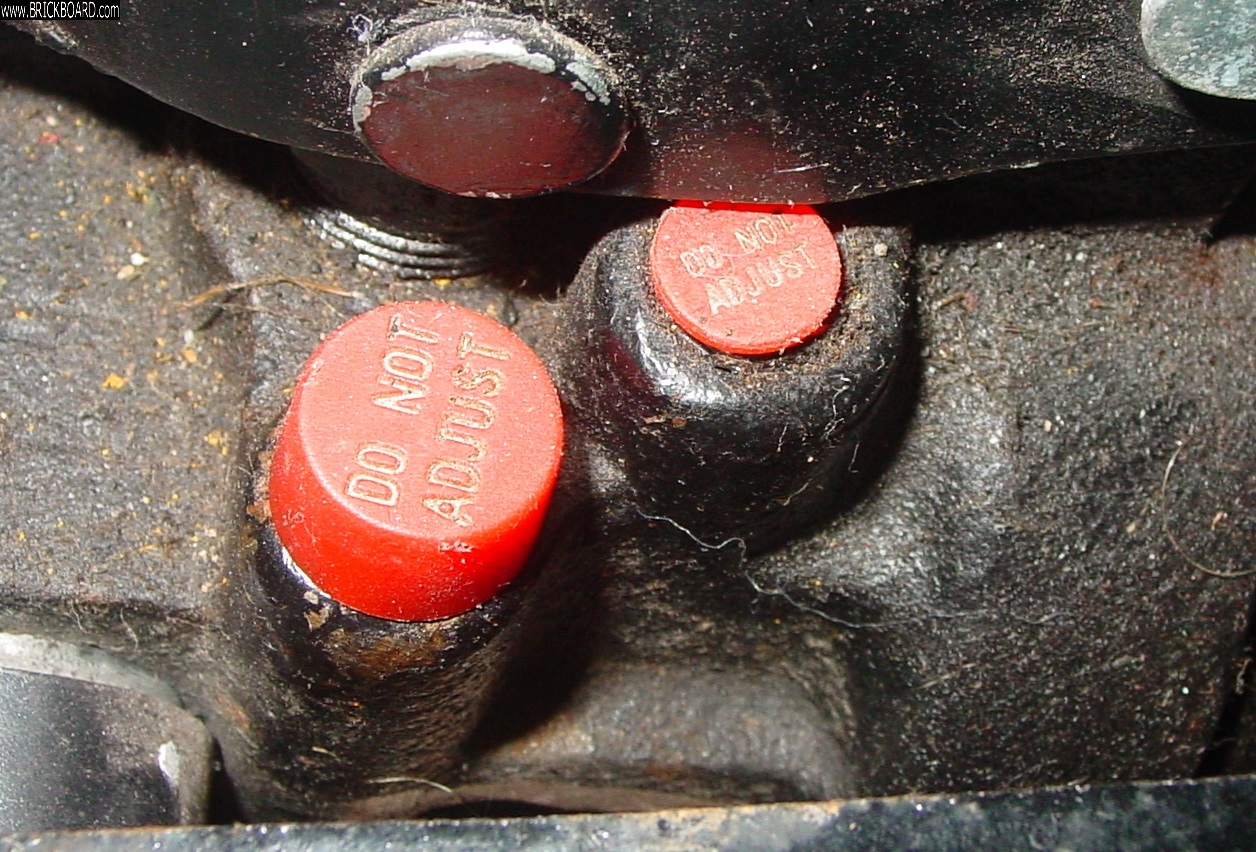

I did not look up why you should not, yet I tightened both of these needle valves to nearly full stop. Doing so increased resistance to both lift and lower about the same whether loaded with Volvo 240 or unloaded.

The leaking stopped.

Sure Happy it's the eggnog holidays!

Miller High Life Light today, in 32-ounce cans for 99¢ each, and more eggnawg.

--

Beh.

|