|

Hi Bill,

You never said how badly the old caps were out of tolerance?

->The old caps barely met the requirement. The 470uF measured 450uF, 100uF measured 90uF and so on. Only the tantalums remained intact, however I replaced them too due to age.

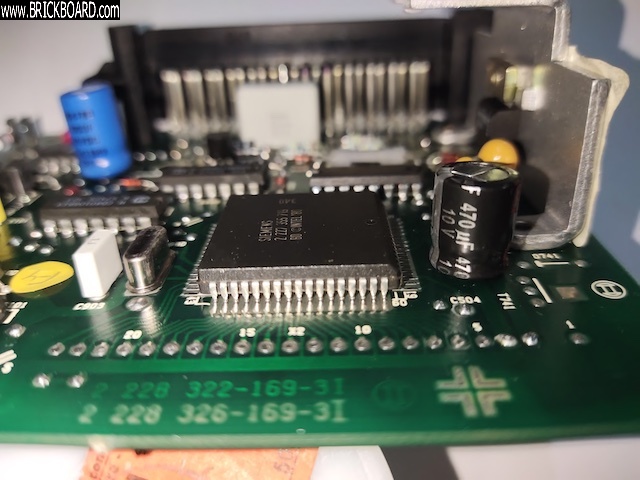

The non-turbo EZK box

The new 470uF cap

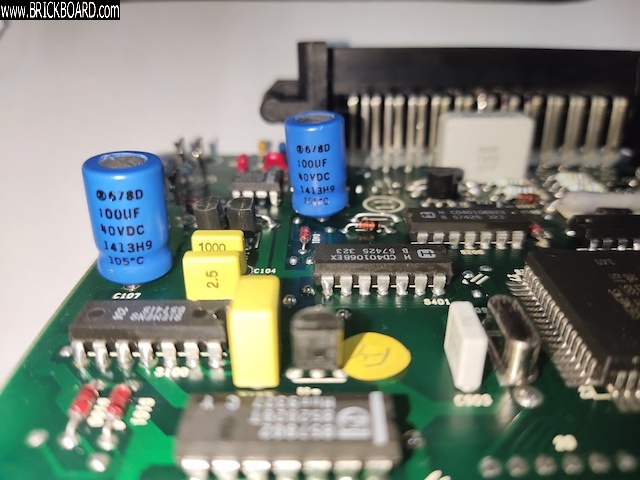

The new 100uF caps

The new tantalums (those yellow beads)

This job wasn't as easy as reflowing old cracked solders on fuel relays.

Firstly you need to ground yourself before touching the board, to get rid of any static electricity (on you) that might zap the delicate components.

The EZK board was so precise even thicker new component legs difficult to fit in. Need to shave them thinner or drill the holes larger to fit new ones in. If you drill you'll destroy the PTH (plated through holes) within the board design. So shaving is the only method.

Need to use acetone (or Spook's favourite methyl ethyl ketone with sweet fruity smell) to clean the board afterwards, to get rid of any excess flux. A room with proper ventilation is a must. Otherwise you'll get headaches.

After the job's done, you'll need to recheck (using multimeter) the solder's continuity on both sides of the board. A cold solder joint might not electrically connect the copper tracks on both sides of the board. Overheat them and they'll delaminate, then you'll need to repair the tracks using jumper wires (this what happened to my LH board). I'm more careful now.

While you're at it check other solder joints for microscopic cracks. However, they're not that common on these boards which still use leaded solder during those times. Lead-free solders nowadays are more prone to develop micro cracks.

I wasn't joking when I mentioned "save all these troubles"

Definitely not for beginners.

Amarin

|