|

|

|

I replaced heater core hoses and intake manifold gasket and now it starts and shuts off quickly with the AMM connected, with the AMM connector removed it will start and run very poorly.

I am getting 113, 121, and 322 codes on the OBD. Codes clear by removing neg wire from battery and do not return after starting and immediate stall with AMM connector in place.

Tested IAC,injectors, and TPS as described in FAQs and all function.

So far I am stumped and need a bit of help.

Thanks Dan

|

|

|

|

|

I sprayed some carb cleaner on the intake runners at the head and there is a definite leak on cylinder 4.

It's time to redo this job!

Dan

|

|

|

|

|

Some dumb as* didn't get about 1/3 of the old gasket off the manifold on number 4!

|

|

|

|

|

And just like that it's running normal again!

It was much easier the second time around.

|

|

|

|

|

I see that you think it might be a possible leak around the intake manifold/gasket.

Does it run long enough that you can spray carb cleaner or starting fluid around the manifold gasket and see if it changes the behavior/engine speed?

--

Any twenty minute job is just a broken bolt away from a three day ordeal

|

|

|

|

|

I have wondered if this might be related to the ignition switch so I tried starting the engine and just held the key on once it did start.

The engine ran poorly until I released the key. It did run holding the key in the start mode.

Dan

|

|

|

|

|

Hi Dan,

Th only thing that I know about the start position of the ignition switch is that, in the old days, it used to bypass the ballast resistor.

This was so the coil got all the juice left in the system when the starter was in use.

A ballast resistor was there to decrease the current across the ignition points while in the run position.

I’m pretty sure that the newer electronic systems with transistors handle such current loads without the arcing that went on with those points and condenser needs.

Whether or not ballast are used today or not is beyond me!

I hear occasionally that some coils are special on these Volvos but I personally haven’t seen it.

I have noticed various replacement coils will note it being “internal” but to be used on what ignition systems, I have no idea.

So you are saying this engine is now, “dead in the water” with the key in No.2 the run position.

It is hitting and running poorly in No.3 the starting position?

Weird ignition issue I will say!

Something seems a miss with the coil connections and the power relay behind the battery?

Something’s broken or wired wrong all right!

Check the power relays actual base and the connector onto it.

I have one that was cracked before I got the car.

I found it while I was servicing it for corrosion.

I ended up wire tying back up tight due to one of the side clips broke off.

I ran the ties underneath and around under the connector.

It works fine, I just haven’t gotten around to replacing, what works, yet! (:)

I hope my brain skimming help you find something soon!

I’m wrestling with a starter solenoid issue myself.

It use to failed to engage after the engine was hot. AAA would jump it and it fired right up!

Goes eight months and it did it again.

Of course, I let it set for six of those months for a summer time rest. I had my warning!

I shared my conundrum with a local rebuilder and he advised me to put on a BOSCH relay system to the starter solenoid.

He says the solenoid doesn’t get enough voltage from Volvos ignition and clutch switch system?

I put that on to the tune of about Fifty Bucks! List $71.

I have the kit number, if anyone is so stupid as I!

One 30 amp Bosch relay with a socket, a 15 amp fuse holder and three wires!

No loom but a Bosch labeled bag with BOLD printing and illustrated instructions!

Now instead of not cranking, it cranks and keeps running, sounding like a vacuum cleaner!

That is until I pull the negative cable!

It stuck on twice out of five repeated starts!

It did that once before in the car before I pulled it.

The rebuilder tested it for me. Clamped only in a vise and said it was good!

I think the motor load draws more on an engine.

The whole solenoid has now gone totally bonkers, up inside the contact plate box.

Talk about breaking down slowly!

There’s no repairing it, but it’s going to get ripped, if and when, I can find one to buy somewhere?

Any suggestions guys! I’ll probably have to go to Napa or a MACYS department store like an AutoZone?

The rebuilder will only order them so I guess he doesn’t even want to stock them!

He said 1990’s use a planetary gear made of metal. No more parts!

He said if it blows up throw it away!

I like this guy, but he didn’t say what he would want for ONE solenoid either!

I can only imagine!

If too hard, I will put an older Direct Drive Motor unit on of an 1980’s cars!

I have never had a problem like this before. These 1990 to 1993’s are different!

Anyways, that’s my story to go along with your pain and suffering, Dan!

It’s A real knee buster for me having to play with this!

I’m in the wrong home without my car lift!!

DARN ole’ wet winters, anyhow!

Phil

|

|

|

|

|

Hi Phil,

Your solenoid problem should probably be in a new thread, but while you're here

https://www.ebay.com/itm/261006599727?fits=Model%3A240%7CMake%3AVolvo&hash=item3cc534a62f:g:qgkAAOSw~BRcF-1l

I've replaced several solenoids on Volvo starters and never had to pay more than $20. or so. They've all been fine.

I believe I've read somewhere that the older, heavier starters don't turn as fast as the later models. They may not be as effective at activating the CPS if you're putting it into a 2.4 car.

The 2.2's would probably start easily with a hand crank, but the 2.4's are a different animal.

Peter

|

|

|

|

|

Hi Peter,

You are right! It should be another thread but I was matching a pain with pain for Dave and some entertaining read!

Thanks for the feed back!

That’s just the place I went to get a solenoid.

I bought the 39.99 one though, because I saw the copper looking studs to hope they went all the way through.

The free shipping was from within California!

Yours has the same deal but I slide away from things that seem too cheap to be true.

Yes, they can make the solenoids for as low as $4 each @10,000+ batches.

Land or Air Shipping space isn’t staying @ $15 a cubic foot either!

I have been bit before over “shipping” on two items that were completely wrong.

I paid out a bunch of shipping charges due to computer invoice errors on his end.

Returned items had different prices credited going between the two invoices that didn’t talk to each other. My card was used too easily to make it look like a new order when it wasn’t! A mess!

I don’t do business out of Florida State, anymore ever, for anything!

Cons area everywhere, there, IMO.

Without saying who it was.

That port is to “Rich” for me and its proprietor was an ASP for not covering his errors!

I never though about cranking speeds affecting proximity sensors?

Either starter outputs are 1.4-.7 KW or about Two Horsepower. The turning speed could vary maybe 50 rpm. It would still be an interesting experiment, nonetheless.

Their speed sound is different due to planetary gearing to get the torque up from an armature’s speed when it has less iron.

The size and weight are the harder driving factors today and cost is sometimes along for the ride as a third rail!

I agree the 1990’s up w/ 2.4 are different animals.

Especially the 1993 with its very subtle changes!

Now that’s another thread! (:-)

Phil

|

|

|

|

|

Thanks, but I don't think there is a starter or solenoid problem.

The engine does start but stops running when I release the key.

Dan

|

|

|

|

|

Hi Dan,

So sorry for your pains!

I will try to think and talk through some things with you to see if we can shift out thinking into another arena of logic!

Well since it’s not a Diesel engine, cutting off the fuel or throwing a sock in it, you’re out of luck for finding that to be a cause for this stopping.

It is either fuel or ignition, since it runs and you get both over in the start position!

I wish I knew what was not connected that is getting bypassed over in the start position?

This is electrical. There is a orange wire in the AMM connector that you need to put a small test light on.

This orange wire feeds power to the whole circuit of the AMM and fuel injectors and comes from one-half of the system relay. I know you changed it and apparently it works during cranking but I think we need to observe if it’s dropping.

With this clue, That makes it more of the ignition switch a suspect as it’s the last thing that moved.

I’m trying to figure out what’s dropping out.

The instrument cluster goes blank while cranking, except for the alternator as system light.

Voltage does drop way down and all that is expected.

What happen with the instrument cluster at the same time when you release the key?

What happens? Does everything come back on bright quickly?

Could there be a bad connector under the dash that goes to the EZK system from the ignition switch?

Art has brought that up before with a picture of a connector that was kinda yellow?

But does it come from the ignition switch?

Did you replace hoses on top of the heater core or around to the heater valve?

Anything like that in the past?

Phil

|

|

|

|

|

Thank you Phil

The power wire on the AMM is red/ black?

Dash lights are all on during start up, and shut off when running.

I have not replaced heater hoses inside the cabin.

Yesterday I replaced the TB gasket and it now starts and runs with the key released to the run condition. It runs but very poorly.

I did replace the distributor due to one of the spring clips breaking. I'm pretty sure I got it back in the engine correctly as I just verified distributor timing with #1 cylinder at TDC the rotor was pointing at the correct position. I'm pretty sure you can't mess this up?

Thanks

Dan

|

|

|

|

|

Please double check the integrity of the accordion air intake hose. I know you said it seems fine, but unmetered air intake is seemingly a likely issue and that spot can dump in a ton of unmetered air on an inconsistent basis, enough to affect both starting and running. Also check the hoses to the IAC valve. Splits in those hoses often happen on the underside and are sometimes difficult to spot, open when the hose is clamped in place, opening/closing slightly during engine vibration/torsioning, but closed when removed for inspection. You've had varying symptoms that seem to change when you swap or move things around, especially the AMM. You may be chasing multiple problems. One thing that jumped out to me is working around the intake manifold and swapping the AMM making major differences, so split/disconnected hoses, loose clamps and loose/poor wires/connectors are all things on your hit list in addition to failed/failing components. On the AMM connector, peel back the boot and give the wires an extra push in to ensure full contact. Also make sure all the big wiring harness connector blocks are fully seated and the wires there are not loose, chafed or damaged.

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

|

|

|

I left 1/3 of #4 gasket on the manifold!

|

|

|

|

|

Yes the accordion has been checked and rechecked, I replaced the TB gasket the other day and the engine now runs after start but still roughly. I am convinced I need to remove the intake manifold again to see if something is wrong with it.

The AMM will need to re-learn it's best setting.

It is running better but not like it was before the gasket replacement.

I'm getting there!

Thanks

Dan

|

|

|

|

|

Hi Dan,

I guess the final resolve might be pulling the intake back and running a straight edge across the face of the manifold.

I have seen many a cast iron manifolds go into twist. I’m sure it’s possible for aluminum ones too!

It’s impossible to spot warp without a test with a straight edge. Especially on the car still.

A person cannot just sight down the front and spot each flange in relation to each other’s bolt holes.

If it is warped the studs are hold the manifold.

Their not made to twist it back flat very much if at all.

A manifolds tube structures are quite massive by comparison.

Another thing I want to bring up is the “type” material or even the amount of gasket thickness that I have noticed between manufacturers.

I have taken off a couple manifolds where the gaskets were obliterated in more that one place.

They had holes that were literally scattered, like Swiss cheese in them!

Surprisingly just how many thin small holes of deterioration that hadn’t even lead to the outside.

I surmise that these gaskets were very thin to begin with and got thinner with their aging.

We are dealing with gasoline and engine oil vapors that contain cooked out petroleum and their chemical additives!

The choice of materials to use is not so basic!

Just to add some perspective to this vacuum physics thing … with 20” of idle vacuum, there is a column of air, one inch square, trying to get inside that vacant area.

It might not seem like much, but it’s 200,000 feet high!

It’s that last little split between the outside and inside that we want to keep to a minimum amount of exposure.

It’s the reason for thin but with some manufacturers, it’s an obsession.

But like most things in life, there are limits and compromises!

I have purchased parts store Over The Counter gaskets before from known brand names and store brands and there are differences like cuts of cloth for dress suits!

These are for mainly non-critical gaskets!

Head gaskets are made to higher standards, due to their locations, but the demand of the job at hand is the same!

Now the original gasket on an engine faired better than the others that were right out paper thin.

Those told me they were non factory or even OEM.

What I’m saying is, the factory gets the best shot at making the car right, the first time!

Paint jobs, welding and assembly!

Everything is made to fit, “within reasonable tolerances”, but they even used thicker gaskets?

Why … for the reason just stated!

They wanted it to get off the assembly line and past the dealer for a few years!

This is where early Volvo shined because of several combined efforts throughout the corporation!

Not perfect, because perfect doesn’t exist, but the stars do align for a short time! (:)

Do not put on the thinnest gasket, especially on a used heat stress relieved engine unless you know all is flat!

I do not use Fel-Pro intake gaskets. They make good gasket material but in our application or with used manifolds, I would not recommend them.

I have to track down Victor-Reinz products for being a more “substantial” gasket material, IMHO and more like what the factory used to get the parts to seal. It’s thicker and more forgiving.

They are a little harder to find, for whatever reasons beside profit to chain stores!

I think they are worth a few more dollars, on my bottom end!

So … if you decide to jump under the manifold, consider all that air standing above your head and squeezing on your body’s suit!

(:-) Your gasket is only skin deep, but it renews itself!

Phil

|

|

|

|

|

Hi Dan,

Well now, that sounds like an improvement!

Amazing that you only changed the throttle body gasket. Was it in some sort of terrible condition?

I don’t get what about the ignition switch had to do with that? Mysterious?

I know the AMM cannot work correctly with “any kind” of air leakage behind it.

When you say it runs poorly, I assume, you mean it is shaking a lot on the motor mounts as a description.

Is it hard to start back up right after a shut down? Or does it tick right over?

I’m trying to determine the conditions of “ignition spark” and “cam timing” that you mentioned is pretty hard to mess up.

The rotor button “pointing direction” is not accurate as you would think. It has a wide tip for a reason.

Do you have a strong thick spark out of the coil wire to a strut tower stud?

Check for the crankshaft and valve cam marks to be absolutely together!

You would be surprised how many times you can keep doing “the same wrong thing” over and over when you work by yourself without a sounding board reference!

Don’t discount these things happening.

If it is hard to start, as in like not getting fuel quickly or having to catch up from a too rich mixture that in itself are to different kinds of running poorly. Both cause shaking.

I have read many times, that the timing belt being off one tooth, can create a mind twisting so badly that nice normal words don’t always come out, even though, it supposedly stress relieves! (:)

I have gathered up the idea that this car needed a lot of “work orders” completed!

Heater hoses never jump to the top a pile.

There has to be an explanation at the end of one of them!

Phil

|

|

|

|

|

Yes we are going in the right direction the old TB gasket was pretty thin and oil soaked and convinced me that the rest of my issues are hopefully with the intake gasket.

The engine starts quickly just runs rough, like it's missing and it is running rich.

New plugs, wires, cap, and rotor. Also cleaned the TB, IAC valve, and PCV system.

I may re-tension the TB and then remove the intake manifold for shi*s and grins!.

|

|

|

|

|

Hi Dan!

I especially like that last part of this post about the Shi and grins!

You're my kind of man!

(:))

Phil

|

|

|

|

|

Did you ever revisit the possibility of an unmetered volume of air entering around the new intake manifold gasket?

--

Any twenty minute job is just a broken bolt away from a three day ordeal

|

|

|

|

|

Bingo I had not removed about 1/3 of the old gasket on #4!

|

|

|

|

|

Great news!

Why is always seem to be number four, ah it’s the farthest away, of course!

Disregard my other post, as most people will too, it doesn’t apply to left over gasket anyways!

(:-). How much peanut butter do you like with your jelly? (:-)

Phil

|

|

|

|

|

It stays running but poorly when started with the AMM disconnected.

Thanks

Dan

|

|

|

|

|

If you haven't pulled the manifold yet, hook up a vacuum gauge and see if it is on the 20" side or closer to 0. If you give it a squirt of ether will it fire ?

As long as you are grasping at straws - Before I looked up the codes I thought that maybe you disturbed the crankshaft position sensor when you were changing the heater hoses.

It is something simple. I struggled with my H Farmall for days because it wouldn't start. I went through the entire ignition system only to find that the wire on the ignition switch was loose. It was close enough to make a spark but not tight enough to fire a cylinder.

Greg

|

|

|

|

|

I did disconnect it, I may have Disturbed the grey connector on the firewall?

Thanks

Dan

|

|

|

|

|

Hi fellows,

Yes Art we are talking to a seasoned Volvo veteran and it’s hard to suggest what he is missing!

After reading your suggestions about the pins on the AMM I figured that you had a very good point and as usual you are closer to naming that tune than I.

I did give it more thought and move my mind just a little bit father back. I worried about the accordion hose have a crack around where the hoses connect onto the hose ports.

But he is well aware of all those possibilities too?

That only leaves the flame trap system not fitting up tightly or the hose from the IAC, but again, I was thinking over to least look into thing on the car that’s getting him!

LIKE he said, he must be missing something “simple.”

It could be all the way back down to the gasket he put on and I agree, it’s pretty tough to mess that up unless it’s not down flat. Like caught up on a wire or something?

I have even thought about if the TPS connector wasn’t connected or even got mixed around with the IAC one but I didn’t want to be one of those “turkeys” that has thrown enough thoughts that we end up with rabbit stew for Thanksgiving.

Yes, I hope he finds it before Christmas. If not, I will have to send him my nice round piece of plywood wood that my step father gave me to keep in my tool box.

It has letters “TUIT” carved into its face! (:-)

Phil

|

|

|

|

|

Accordion hose is fine. IAC and TB connectors are different. I don't think I took off the oil pressure sender connector and I think it has a pretty short wire so you can't switch them.

What kills me is it ran fine and very reliable for my daughter for many years now.

Dan

|

|

|

|

|

Above I was referring to the ETC sensor,not the oil pressure.

|

|

|

|

The ECT and its wiring all the way up to the ECU should be fairly easy to check with an ohmmeter.

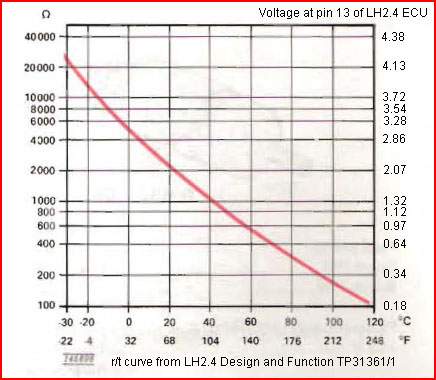

With the ignition switched off, unplug the ECU connector and measure with a DMM set to Ohms between pin 13 and ground. Note: to prevent damage to the reasonably fragile contacts, don't measure from the front but take off the sleeve and measure from the sides of the contacts.

If all is well, TP31361-1 section E14 says that the measured value should be:

-10 C/14 F: 8,260-10,560 Ohms

20 C/68 F: 2,280-2,720 Ohms

80 C/176 F: 290-364 Ohms

For those that don't already have that Volvo service manual, it can be found here.

If the ECT turns out to be fine, I'd suggest to start the fault tracing section from the beginning and run through the steps one by one. Every single step should be checked, even if you think you already eliminated a particular item or have the assumption that that item cannot possibly be the cause. Almost all of the steps can be checked with a DMM in either Ohms or Volts measurement setting.

Good luck!

|

|

|

|

|

Thanks for the link to the manuals, much easier to read on my 27" screen!

I will run through the diagnostics before tearing things apart again.

One thing I noticed was 2 sets of ground wires (3 grounds) on the front of the fuel rail. I'm not sure I have that.

I do have a running 240 I can refer to when needed.

Dan

|

|

|

|

"One thing I noticed was 2 sets of ground wires (3 grounds) on the front of the fuel rail. I'm not sure I have that."

Yes, those are the grounds Art was talking about and they are quite essential. They should go to pin 20 of the EZK (link), and to pins 5/29 (signal ground) and 17 (power ground) and 19 (code plug or ground) of the ECU (link). Not familiar with "code plug", according to the service manual, pin 19 is also connected to the manifold. LH Jetronic was also used by Porsche and Saab, so perhaps "code plug" might be relevant for them.

The ECU and ICU are only grounded through the wiring loom and not locally to the chassis for noise suppression reasons.

|

|

|

|

|

Thank you, my 93 and the 92 both have one ground wire per connection so it looks like the 92 is correct. I will test both ECU and ICU (EZK) as you and Art have instructed.

I took a break today but will get back to it tomorrow and feel pretty confident I will find the problem with a little help from my friends!

I do have a spare EZK I can swap in for testing but realize these pretty bullet proof.

Dan

|

|

|

|

... my 93 and the 92 both have one ground wire per connection...

Those single wires are supposed to represent power grounds on one bolt and signal reference grounds on the other. Here's a picture revealing how one wire you see is the join of multiple wires under the black vinyl sheathing.

There have been reports here of folks fixing these splices to resolve sticky troubles. Hasn't happened to me though.

All of the engine management grounding returns to the intake manifold, which is bolted in 8 places to the head, and back to battery negative through the head bolts to the block. All meant to be very reliable connections.

--

Art Benstein near Baltimore

Spectator sports offer an alternative to politics and religion for men and women who don't feel quite alive unless they are ranting, shouting, or screaming their beliefs and opinions at their fellows.

|

|

|

|

|

Art

The blue/red wire reads 2.3 ohms on the 2 k scale, that seems normal?

What static grounds should I check for the ECU and ICU.

Should I check any grounds with power on?

Dan

|

|

|

|

|

Thanks Art I will get back to this tomorrow.

Dan

|

|

|

|

|

Hi Dan

I see there was a suggestion that you are grasping at straws, so I will get to gripping a few with you!

Yes the two the oil pressure sender would be a reach, as it’s on the other side of the engine. (:)

I know I said the TPS and the IAC but now that you mentioned the oil pressure I’m wondering about the ECT and the IAC.

The TPS can hang down too but I have only read that it’s possible to connect the IAC. I cannot say I’ve done it!

Since we are all confused with the long and the short of straws here, let’s plugs in the idea, that’s it’s something to do with the ECT!

If its not in the game, then we have just enough of a hand of straw to make up the reason it’s running poorly.

The firewall connector goes to cabin things doesn’t it? Like the instrument cluster?

If the CPS had a play in all of this, I don’t think it would be running without the AMM in any amount. The injectors and spark would have no reference signal to do things correctly.

I sure hope things get simpler right quick or I’m going to resort to chewing on some straws and putting my hands up to really scratch my head!

(:) My wife might start thinking I got a toupee some place! (-:)). CHEAP!

Phil

|

|

|

|

|

You are correct I was referring to the ETC, which I think is too short to connect to the TPS. Besides the TPS tested good with the OBD procedure.

Thanks

Dan

|

|

|

|

|

Hi Dan,

Yes I caught that the TPS passed the test procedure but that doesn’t mean that the ECT connector isn’t still an issue. It is running poorly.

The AMM being disconnected can do the same thing and go in a default, so why wouldn’t the ECT side of a program be showing you similar results if the AMM is working properly?

You have said the car has run for years but all good things lead to other things, good and bad, eventually, no matter all our efforts.

I know, I know, Why Now?

It’s time for good chats on the Brickboard! (:)

A good stew is never made with only one ingredient!

You just got to keep stirring!

Check the vacuum line all the way down to the evaporative canister. They can rot in between!

Phil

|

|

|

|

Offhand, I'd check to see one of the pins on the AMM connector isn't damaged or pushed back after first disconnecting it to get it and its hose out of the way when you did the work.

On second thought, could you have missed one of the two ring lug ground wires at the fuel rail bolts?

--

Art Benstein near Baltimore

4 out of 3 people struggle with math.

|

|

|

|

|

AMM meter connector pins appear fine. I did not remove fuel rail, so I did not disturb the grounds. I did reposition the ground strap on the head, I guess it wouldn't hurt to clean grounds at the rail but all injectors seem to be firing.

Anymore ideas are appreciated, the engine worked fine prior to the hose replacement.

Dan

|

|

|

|

Hi Dan,

The suggestions I made were based on the codes you reported. They all point to having started the car without the AMM connected. So, I was thinking you probably cleared the codes by lifting fuse 6 momentarily and tried again, getting the same results. One of the rail connections is the ground for the AMM -- they aren't just grounds for the injectors.

And I know you're a champion of the wisdom to keep known good AMM and ECU on hand. So the only question left in me is the reset. If you do this by the OBD push button, I can't tell you how effective it is at clearing the trim settings, but I do know lifting fuse 6 (on a 92) will clear everything immediately.

--

Art Benstein near Baltimore

"I been in the right trip but I must have used the wrong car." -Dr John

|

|

|

|

|

Thanks Art

I did reset the codes and they have not returned with the engine running briefly prior to it shutting down.

Yes I have tried the FP relay, AMM, and ECU none of them changed anything. I must have screwed something up replacing the hoses, I may have to pull the intake back again just to check it out.

Do you know if any grounds are attached directly to the intake manifold bolts?

Dan

|

|

|

|

Oh, if the codes did not return (you now get 111) and even so you can't keep the motor running, I'm no longer looking at wires and volts. Unless maybe distributor wires and high volts. Like Phil I'm thinking maybe a serious vacuum leak. The only grounds that matter in this are those on the fuel rail bolts, and of course the big one from the battery to the block. That strap from the cam cover to the firewall is radio noise suppression, nothing more. And if you swapped ECU you most certainly reset the codes. :) You have me stumped too.

--

Art Benstein near Baltimore

An elderly father asked his son if he could borrow a newspaper.

“Father, this is the 21st century,” replied the son. “I don’t waste my money on newspapers. But if you like, you can borrow my iPad.”

The spider never knew what hit it.

|

|

|

|

|

I did new plugs, wires, cap, and rotor just the other day. They were overdue but not the Solution.

One other thing I did was replace the dizzy after one of the cap clips broke. I don't think that would cause a problem? I took pictures, was careful and it ran just like it did before. Started and quit with the AMM attached, started and ran poorly with connector disconnected.

Dan

|

|

|

|

|

Thanks Art

I will re-check both suggestions tomorrow.

Dan

|

|

|

|

|

Hi,

My first thought is too much intake air.

You know, missed a vacuum line and then the brake booster hose popped in my head.

Maybe it has cracked or split on you a tiny bit. It’s a big hose.

Vacuum hoses seem to crack on the underside or backside where you cannot see them!

If you completely pulled the intake far enough, to get it out of the way for better access to those hoses, you may have also done something to the check valve or it’s grommet too!

I had the little center disc plate completely fall out of one check valve after I happened to noticed it was looking dried out. Of course, that was on my 1978 several years ago.

All that stuff is old.

It’s like us older people that don’t care for excessive bone shuffling!

Especially, if things really start to suck! (:)

Phil

|

|

|

|

|

I did remove / pull back the intake manifold to replace the hoses, the hose to the booster stayed attached to the manifold and booster. I just checked the check valve and grommet it does work like it should.

I'm not sure where else a large vac leak could occur.

Dan

|

|

|

|

The end of that hose where it joins the manifold is weak because that's where the blowby oil accumulates. I've never seen it torn open, but just the opposite, collapsed shut right there.

--

Art Benstein near Baltimore

Is it true ants never get sick?

I don’t know, but they sure as hell have anty-bodies.

|

|

|

|

|

I looked at that end of the hose and it doesn't look as collapsed as the one on my 93 240 that works fine.

I guess I have no choice but to pull the intake manifold off and look. I was pretty careful and it looked like it went on flat.

Is there any concern about the ignition switch or fuel pump?

Thanks

Dan

|

|

|

|

|

Thanks Phil I will check it out tomorrow. I know the vac line to the intake manifold is connected, I will see what the rest of it is like. It just seems like it's something simple that I have overlooked.

Dan

|

|

|

|

|