|

GOT IT! Because of your feedback I took another look at my toolbox and noted how a bolt extractor sounded similar to the stud extractor. Well the smallest size (5/16 & 8mm) bit rite down into the meat of broken stud. I warmed up the area around the stud staying far away from the stud itself and hit it with some more PB Blast. Applied steady even pressure and felt the stud move! Amazing how you can tell the difference between a stubborn bolt giving and the same piece ringing off.

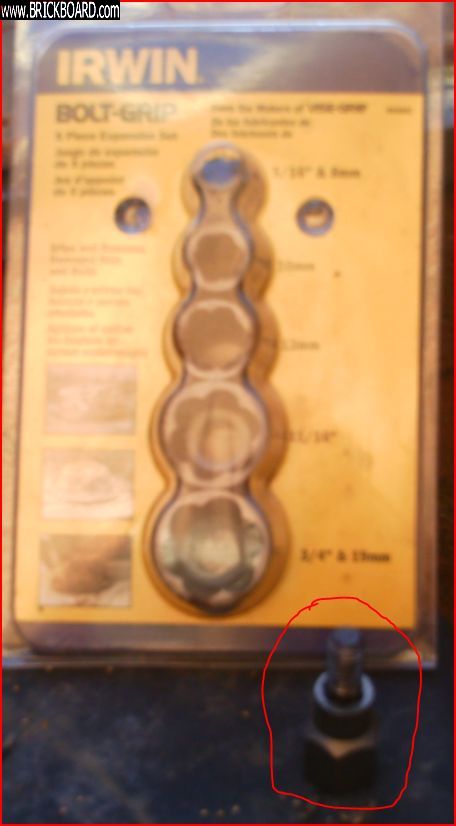

Below is a picture of the tool I used the stud still in its teeth. Next question. Anyone know how to get a stud out of a bolt extractor? Lol!

Thanks much for all of your feedback. It got me to looking at the problem differently.

|