|

|

|

greetings all,

been trolling and searching here for a while, but i have become stuck and hoping folks on here can share their knowledge. I have 73 ES with dreaded FI, end of last year gasoline started filling up in the oil so much so it would be 1 quart over the max fill line.

I pulled the injectors and sent them off to be reconditioned, upon installing i had same issue. I have not been able to find inj, i tried and failed with crap on ebay only to find all the inj they were sending me only fire at 12v not 3v.

I eventually found VP autoparts who sent me new aftermarket injectors (i still ended up using my orig seals as new ones they came with were rubbish) and have a no start condition.

so i did:

1. cleaned FI contactor and have 3V to each inj

2. cranked engine with fuel rail / inj disconnected from block, and i have gas to all 4 injs.

3. installed gauge on the rail and i have 28 -30 lbs fuel pressure.

all 4 cyl compression check at 125, the engine has 98k on it

i have been trying to start car now for a week, it appears i stil have same issue, car wants to start then dies immediately, overnight the fuel pressure falls back to zero and i have the oil above max mark and climbing and the engine has yet to start and run..... what am i missing here gents?

the engine has not run in 8 months, i have drained tank and put fresh gas, frustrated and about to give up on this thing.....

thanks in advance,

--

Rob

|

|

-

|

|

|

Hi, sorry to hear of your downturn in health. Unfortunately we’ll all be subject to that at some point. Probably not many golfers on this forum, but as the late Sandy Tatum said:

“Instead of worrying about what you no longer have, figure out what you still have left, and make that work as well as you possibly can.”

Sounds like you’ve got that figured out.

Hope you get the 1800 sorted, and all the best.

|

|

-

|

|

|

Hi, sorry about the continued frustration. At this point if the temp sensors check maybe it’s the ECU?

I don’t have enough knowledge to say it is, but I’ll do some investigation later today.

Maybe planetman has a good known ECU to lend you.

Also an ECU can be damaged by welding on the car, and high heat such as being baked in a heat booth during a respray. Did you have either of these done or by a PO?

|

|

-

|

|

|

greetings & happy sunday All,

no, have not performed welding or spraying since i owned. Carbs - yes i have already bought a 1973 Jensen interceptor.

So i was finally able to kajole a mechanic to come over the house (bribery in evidence here) he is not familiar with volvo of any kind let alone vintage but is a gr8 in diagnosis. On first crank, he said too much fuel, he disconnected to CSV and backed off the fuel pressure regulator until the screw fell out, first crank after that it was running on 2 cylinders, as we had the other disconnected. 2 minutes later we were purring away happily, if it were down to me i would never have got it to start as i used my pressure gauge to set nut at 30lbs and locked in place never to be touched again. The fuel pressure reading on the gauge is 18 lbs and runs fine.

An hour later, i had installed new spark plugs to get good sealing (i had plugs which had been in/out of the head more times than i had hot dinners) swapped back my MPS as a test (it tested good) and set idle speed as well as final timing setting.

So i have now permanently disconnected the CSV and mounted a fuel pressure gauge in its place, i have turned it up to read 30. I will try to start early tomorrow morning when Florida cold to see if it starts. I will make adjustments from there, but i do not think i can stick to book setting as i do not have OEM injectors, the inj are from VP and i have no idea what they are. It is here where my experience & expertise breaks down, i follow instructions and setting, but when that doesnt work i m lost!

I am going to attend to a few other issues - brakes need bleeding now its been laid up so long and sell her on, its just too much for me to handle now i have an ongoing health issue that does not really allow me to do physical work on it all day and i have to attend to other things around the house like cutting grass etc that leaves me little to no energy left. I have spent too much time repairing this car to actually enjoy driving it, i ll leave that to someone else! There is still too much work for me to make this truly a reliable daily driver, and if it cant get to that point the car is of no use to me.

Thanks to all for patience advice and due diligence, a special shout out to Eric of HIgh PErformance automotive of Torrence Cali in providing MPS for swap out testing,

Rob

|

|

-

|

|

|

The Bosch 280-150-036 injectors that were originally supplied with the D jet system are listed in the Bosch Motorsports catalogue as 364 gm/min (492 ml/min) injectors at 43.5 psi. Actual testing by me and others indicates that the flow rate is more like 555 ml/min at 43.5 psi. All vendors generally list their flow rates at 43.5 psi even if they don't operate at 43.5 psi.

Within reason, it is permissible to adjust the flow rate through an injector by altering the base fuel pressure. The relationship between flow rate and fuel pressure is

New flow rate = sqrt(new pressure/old pressure) x old flow rate

If the VP Auto injectors have a flow rate that is higher than the Bosch 036 injectors, it is acceptable to reduce the fuel pressure to a level where the flow rate matches the Bosch 036 injector. However, I would be surprised if the VP injectors are so oversized that they require a pressure reduction to 18 psi to make them work. The Bosch 036 injectors are already grossly oversized for the size of the B20 engine and I am not aware of anybody who made a barb fitting style injector larger than the Bosch 036. .

One way to resolve this would be to send one of the VP injectors out to RC Fuel Injection or WitchHunter (or whoever you hoose) and have it flow tested. If the test results come back saying it has a flow rate in the 500 - 550 ml/min range, then the injectors are probably Bosch rebuilds or one of the aftermarket equivalents. In such case, you have some other problem causing the high fuel flow rates and dropping the fuel pressure is only masking that problem. You need to address that problem whatever it is rather than continue to run at 18 psi.

If the test results come back indicating an injector flow rate much higher than 550 ml/min, then within reason it is fair game to adjust the base fuel pressure down to get a flow rate that would match the Bosch 036 injectors. Once you know the injectors actual flow rate you can calculate what the correct base pressure should be using the preceding formula. You need to be cautious with this approach because the Volvo fuel pressure regulator was designed to operate with a base pressure around 28-30 psi. It may or may not operate reliably at a much lower pressure (control pressure may fluctuate depending on how much fuel is being by-passed).

If the VP injectors come back from testing with a flow rate higher than 500 - 550 ml/min, I would be inclined to complain to VP and request a refund. I would replace them with the Beck Arnley 158-0438 injector which a number of users have confirmed as a perfect replacement for the Bosch 036 injector. If you shop around, you can find them on sale for less than $40 each.

|

|

-

|

|

|

greetings!

so i have been letting the car idle for a few days, i have set pressure back to specs (28-30) and we again have my old issue of gas dumping into oil, i have already climbed past max level on stick only after a couple days - another oil change & filter!!

So at this point i m going to set it back to 18 lbs, thats the sweet spot the mechanic found, as soon as i m physically able to get my 200lb trolley jack out, i will bleed brakes so i can test drivability, i ;ll report back as soon as i know, but i fear 142 guy is correct!

I will be certain to print out this chain as i pass the car on, i m not really inclined to start pulling apart injectors for return / refund / testing purposes.

Eric of old volvos in Cali,

i return ship MPS you kindly lent me this weekend, I believe we found root cause now.

Two off topic items - 1. With regards to Jensen Ron mentioned yes i m thinking of selling as it appears my 'garage hobby' has to change now with my recent health condition.

2. In my quest for parts & knowledge i have come across John, phone number 518 232 2682, he has a ton of 60's p1800 parts & panels, please post this so guys can get in touch with him.

web admin please post this detail where folks can find, hes an older gent so not computer savvy he prefers telephone & is ok with me sharing here,

--

Rob

|

|

-

|

|

|

Robin;

Thanks for the follow-up...I'm happy the engine is finally purring (at Idle anyway) although I 'm quite leery of Injectors needing 18PSI to do it...there's something to be said for that mechanic's experience and immediately seeing there was toooo much fuel being delivered!...I cant speak to the flowrate of the VP injectors and what the different FPReg setting wants to be (or if these should even be left in the car), but this needs further studied and understood as the whole D-Jet Sys is based on a supply rail pressure of 2.1ATU (NOTHING ELSE!), and if these Injectors need half that, I don't think the ECU will be operating within a normal range throughout the entire RPM/Load/Operating Range (ECU doesn't monitor fuel pressure, it assumes it to be correct, and some of the calculations it makes I'm sure are non-linear, so these calculations would go out the window with a low fuel pressure!)...if these Injectors are flowing too much, my advice is, to install the correct Injectors, else you are engineering a new totally D-Jet configuration, and you don't want to do that, and really can't without an engine dyne plus exhaust gas sensing and analyzing...!

I'm sorry for your health issues...I suppose everyone needs to know their point of when to "cut bait", but it seems like if you've got the car running now and just need a Brake Bleed you are in the home stretch...besides, I can only imagine what surprises, pain and suffering that Jensen will provide you with...

Cheers

|

|

-

-

|

|

|

C1800;

I sometimes say "no news is good news", but I hope if he has it sorted, he posts back with experience and results so that we can all learn from it...or maybe figure out how we were indeed "barking up the wrong tree"...

Cheers

|

|

-

|

|

|

Ron, yes, hope he posts back and let’s us know.

|

|

-

|

|

|

He got the good used test vacuum pressure sensor I sent.

He hasn't had a chance to install it yet.

--

Eric

Hi Performance Automotive Service (formerly OVO or Old Volvos Only)

Torrance, CA 90502

hiperformanceautoservice.com or oldvolvosonly.com

|

|

-

|

|

|

greetings Eric et al,

sorry for the delay, nearly did not make it, a routine outpatient op went haywire landing me in ICU for a week!

I digress, so i have been laying in bed anxious to test new part Eric speedily shipped to me, (many Thanks to Eric!)

To catch some of you up, i have been trying to get this beast going for 9 months now. (new everything from valve cover gasket upwards) So having installed replacement MPS, i am cranking....cranking and Sigh to no avail, still nothing.

So i do not understand why i do not even get an attempt to fire, i have gas, spark and compression; the 'CPU' in this instance is not digital signal(or at least to my knowledge, all signaling looks to be analogue.)

Maybe one of our electronic engineers can opine, typically i have an engine light or code to work off for diagnosis but in this case i am completely lost. I wonder if any of our electronic engineers could read the diagram of the MPS and interpret which of the 4 prongs to short in order to get a firing condition.

I am still not quite well yet, but when i am later this week, i will check the timing again and put fresh gas in the tank. I do not think gas is bad yet, its about 6 weeks old and low in the tank - i just want to rule out completely before giving up on this thing.....

thanks in advance all,

Rob

--

Rob

|

|

-

|

|

|

From outpatient to 6 days in ICU is indeed an unfortunate turn of events. You have my sympathies on that unplanned turn. Cranky Volvo P1800s rank way down on the list of important things at this point.

I reinforce Ron's comments. If the cold start valve is operational during cranking and the ignition system is reasonably close to being correctly timed, I would expect you to be getting some sort of engine activity during cranking. At the very least an occasional phfft from the tail pipe indicating an ignition event. Even if the D jet was mostly dead, the fuel from the cold start valve should allow a tiny burst of engine operation until the fuel supplied by the cold start valve runs out.

How wet are your sparkplugs? Is it possible that with all the testing they have become fuel fouled? External ignition testing lights may still indicate correct operation; but, if the spark current is leaking down the nose of the sparkplug insulator you won't get a spark across the gap and without a spark across the gap that equals a no start condition. Removal of the plugs to confirm the presence of spark across the gap would be a no cost test. If the sparkplugs look dodgy, replacement might be in order.

I am an electrical engineer; but, like a clinician I need some symptoms to make a diagnosis. The only thing I can definitively say is that since your fuel pump goes through the prime cycle when turned on, the D jet controller is not completely dead.

- Did you do the throttle open and close test and listen to hear or check the injectors open and close as you opened and closed the throttle all the way?

- Did you check the operation of the D jet contacts in the distributor?

- Have you checked the resistance of the air temperature and coolant temperature sensors (I seem to recall you verified the CLT)?

If you have done all of those items and you have a known good MAP sensor then the D jet should be able to function. Maybe not well; but, it should be capable of generating some level of activity from the engine.

As a final note, if the clear fuel filter you installed is one of those generic plastic filters, that may be fine as means of testing to confirm fuel delivery; but, do not engage in extended operation with that filter in place. Those filters are not designed to sustain the 30 psi D jet fuel pressure. The pressure combined with engine heat may result in a catastrophic failure.

|

|

-

|

|

|

greetings 142 et al,

so been silent for a while, i have been off my feet and holed up on bed rest, having an open wound in my throat i cant take too fuel vapours.

This is current state of play:

1. filled tank with 4 gallons of fresh gas

2. compression tested engine, 130, 125, 143 & 130 (1 thru 4)

3. i pulled out all the plugs and cleaned them - whilst they were out i cranked engine and noticed that with all plugs out fuel only flashed out fast from cylinder #3, not 1,2 or 4. i replaced plug #3, and with the other cylinders open i still did not get fuel coming out as with #3.

I pulled the fuel rail again, upon cranking, i get 4 blobs of fuel wetness - confused - any input here?

4. Re checked and set timing, i have spark to all 4 cylinders.

5. with the help of Eric aka Performance Automotive Service (formerly OVO or Old Volvos Only) i installed the MPS - this was not an easy task i had to remove the stand to mount new MPS, i wanted to make sure the sensor is mounted as i read somewhere its function is sensitive to horizontal back n forth movement.

6. checked that the CSV is operating - it is grounded at temp sender on side of block.

7. I have removed under hood gas filters

Upon cranking i get nothing, not even a hint of wanting to fire, i have stepped up the pressure via the fuel pressure regulator, still nothing.

8. - Have you checked the resistance of the air temperature and coolant temperature sensors (I seem to recall you verified the CLT)? -what should these readings be?

With failing health here, i m ready to give up on this guys, i have been trying to get this thing to work for almost a year now and i think its beaten me,

let me know if you think i have missed something,

thanks in advance,

rob

|

|

-

|

|

|

3. "fuel flashed out fast from cylinder #3" does that mean with the spark plug removed you get significant amounts of gasoline droplets spraying out of the spark plug hole? If so, that is likely a sign of too much gas, either from the CSV or the injector. Were your spark plugs wet with gasoline?

"pulled the fuel rail again ... I get 4 blobs of fuel wetness" What does that mean? Did you pull the rail with the injectors attached and the 4 blobs are appearing at the injector tips during cranking? During cranking I believe that you should get fuel spray from the injectors (best to have 4 bottles to collect spray during test).

4. "I have spark to all 4 cylinders" - How did you test this? Did you hold the sparkplug ground against the block and check for spark across the electrode gap? Really fouled plugs cannot be cleaned. If you have spark across the electrode gap then they should be OK. If you used an external spark tester that is not a guarantee that you have spark in the cylinder.

7. "I have stepped up the pressure via the fuel pressure regulator" - Don't do that. The 28-30 psi fuel pressure should be just fine for starting. It almost seems like you are getting over delivery of fuel and raising the pressure is not going to help.

8. "what should the reading be" - The values for the coolant temperature sensor and the ambient air temperature sensor are specified in the D jet trouble shooting guide which was provided in a link earlier on. If you are within 100 - 200 ohms of the value in the guide at the temperature specified in the guide that is probably good enough. The factory service manual shows a fairly large tolerance for the values.

|

|

-

|

|

|

good morning happy friday all,

3. "fuel flashed out fast from cylinder #3" does that mean with the spark plug removed you get significant amounts of gasoline droplets spraying out of the spark plug hole? If so, that is likely a sign of too much gas, either from the CSV or the injector. Were your spark plugs wet with gasoline?

- all 4 plugs are wet with gas, im not able to perform precise measurement, #3 does not look anymore than any others

"pulled the fuel rail again ... I get 4 blobs of fuel wetness" What does that mean? Did you pull the rail with the injectors attached and the 4 blobs are appearing at the injector tips during cranking? During cranking I believe that you should get fuel spray from the injectors (best to have 4 bottles to collect spray during test).

- spraying all 4 tips, i will get bottles to perform a measurement

4. "I have spark to all 4 cylinders" - How did you test this? Did you hold the sparkplug ground against the block and check for spark across the electrode gap? Really fouled plugs cannot be cleaned. If you have spark across the electrode gap then they should be OK. If you used an external spark tester that is not a guarantee that you have spark in the cylinder.

- grounding plugs at block, spark in my opinion looks weak, but upon changing coil, it makes no difference

7. "I have stepped up the pressure via the fuel pressure regulator" - Don't do that. The 28-30 psi fuel pressure should be just fine for starting. It almost seems like you are getting over delivery of fuel and raising the pressure is not going to help.

- trying to force more fuel to start - if carb i would be turning up gas i dont care abt economy i want it to start

8. "what should the reading be" - The values for the coolant temperature sensor and the ambient air temperature sensor are specified in the D jet trouble shooting guide which was provided in a link earlier on. If you are within 100 - 200 ohms of the value in the guide at the temperature specified in the guide that is probably good enough. The factory service manual shows a fairly large tolerance for the values.

- does this really affect start condition? if so, its time to junk this thing

like i said i m ready to give up after a year this has beaten me - im thinking of post in the listings and see what offers folks can come up with i d like it to go to a good home rather than a flipper

thanks in advance all!

|

|

-

|

|

|

Agreed. It seems like its probably time to sell and move back to something with carburettors.

|

|

-

posted by

someone claiming to be Patrick of M

on

Mon Oct 7 11:21 CST 2019 [ RELATED]

|

|

You don’t need to sell, just get a set of SUs and intake manifold. Sell all your d jet stuff you will break even(some people love that stuff). SUs rule!

|

|

-

|

|

|

hello Patrick & friends,

me again with the PIA beast again that wont run; kinda my fault this time:

so battery was draining down and alternator quite charging, so i removed sent away to rebuild, i was careful to mark wires on back so as not not mix up, i got it back and put it on but in so doing i did following:

1. i got the 2 hoses mixed up going to intake manifold causing kickback n hard start

2. playing around with hoses on intake i broke the connections to the temp sender near the thermostat

3. i forgot to take pics of hoses so i was in guessing game as to what was where, when the car did start briefly it ran at 3k rpms

4. my car is not per book as i have discovered this weekend that the aux air valve doesnt work so it was blanked off.

4. i bought new clamps n hoses, panetman told me crank case hose goes before butterfly

5. i blanked of aux air valve and the opening behind butterfly on intake manifold

so now i crank away like crazy not even an effort to fire:

a. check for sparks

b. check for fuel turned up pressure abit - now i have leaking fuel press reg - slow leak from top

so any ideas where to start?

note i have 22 lbs to the rails, i was running beautifully with 18 before, i have these VP inj from VP that wont work at 32,

thanks in advance

rob

|

|

-

|

|

|

forgot to mention

i lost throttle stop, it fell out somewhere so i replaced but the position is a guess, it should not affect starting with my foot on pedal?

thanks in advance

R

|

|

-

|

|

|

Rob;

...wishing you a good recovery!...when you go in for outpatient work and wind up in ICU, nobody needs that kind of "upgrade"...

...sorry to hear about you continued no-start condition...even after replacement of the MAP Sensor...yes, the ECU is all analog (see: https://www.sw-em.com/bosch_d-jetronic_injection.htm )

"which of the 4 prongs to short in order to get a firing condition." ...sorry...it aint as simple as that! ...the MAP Sensor is a complex variable transformer which takes into account outside air pressure and manifold vacuum. There are no terminals to short on it which will magically fix anything...!

With the No-Start condition persisting, even with Eric's known working MAP Sensor, I'm thinking you are missing something simple at this point, and your troubleshooting either deserves your own fresh, un previously biased look at Fuel delivery (6 week old fuel has no old-fuel issue!), Ignition and Timing, Compresion, OR an outside D-Jet experienced troubleshooter, as we have covered in this lengthy thread everything which you should need to Start....hell, I'd have poured fuel into the intake manifold at this point already, to separate Fuel Delivery from Ignition, and attempted started it...even if Timing was WAAAY off, I still expect occasional signs of life from the engine...Relook!...I think you're missing something simple...!

Wishing you also: Continued Good Hunting!

|

|

-

|

|

|

Rob, sorry to hear of your OR mishap. Glad you made it!

6 week old gas should be ok. I can’t recall if you have a clean tank or not, do you have the correct fuel filter, both in line and in tank? Testing on a full tank may help if there are any issues with the pickup tube. Any issue with sediment in the tank?

Rest well, we’ll await your full recovery and MPS changeout.

|

|

-

|

|

|

greetings All!

I had 1 or more injectors stuck open dumping excess gas into the oil in the dec/jan 2019 time frame; it was at the time i pulled fuel system apart and cleaned (incl installing new injectors). Filters are new, i also have a clear aftermarket filter under the hood as a visual whilst diagnosing start issues; I have the fuel pressure regulator set at 30lbs with a pressure gauge inline for verification. I also have inline spark plug testers setup so i can verify spark to each cylinder.

From what i remember i think compression test was 130ish on each cylinder, nothing unremarkable, easily within the spec as i recall.

I went back and set the timing per Ron K's instructions.

Hopefully i will be somewhere upto 75% functional by the weekend so i can take a better look at what i have got; I will recheck timing, put 5 gal fresh gas and see if i can coerce her to start with starting fluid. If that does not work with Eric's new MPS i will be very disappointed,

Thanks in advance,

--

Rob

|

|

-

|

|

|

Rob,

When the damper pulley timing marks read TDC, is the distributor rotor pointing at the number 1 spark plug lead AND is the #1 piston at the top of the stroke? (A plastic straw in the spark plug hole is probably accurate enough for this if you don’t have a dial indicator.) I’m starting to wonder if the woodruff key hasn’t sheared or the cam gear hasn’t spun a bit on the center bushing.

|

|

-

|

|

|

HI Rob, some more posting for your consideration as you recuperate.

I recall reading somewhere (and I've read a lot) that the D-jet doesn't take kindly to a fuel filter after the pump. Suggest you eliminate that. Also I recall reading about a non OEM type fuel filter before the pump can cause problems. Would be a simple fix if those were the problem, but it may be worth remedying the filters.

Rest up

|

|

-

|

|

|

So it appears your MPS is ok, The CSV, might be funky, but it should still run. Injectors are new and tested. You mentioned the injectors seals were new, but they didn’t look good so you used the old ones. Maybe a new good set us in order?

Have you tried starting fluid in a spray can? If you have spark, timing is set, and no huge vacuum leaks it should run for a few seconds on starter fluid.

A quick check on a broken valve spring would be helpful first.

https://en.m.wikipedia.org/wiki/Starting_fluid

|

|

-

-

|

|

|

This thread is getting rather long but I'm adding that Volvo upped the working pressure to 30psi from 28. Owners have also used 31 and 32 psi to keep the mixture from getting too weak at very high revs.

|

|

-

|

|

|

Pull the valve cover and find out which intake valve spring is broken.

A bad CSV will not keep the engine from starting, just cranking longer than normal.

--

Keeping it running is better than buying new

|

|

-

|

|

|

even though cold compression tests ok? I have 135 across all cylinders

rob

|

|

-

|

|

|

I am not a fan of the broken valve spring theory. B20 engines are noisy; but, I think the noise associated with a dropped valve would be extra, extra noisy and obvious and you definitely would not be running even pressure on all cylinders.

If you have confirmed you have spark and it is static timed to slightly before TDC, it should start if it was getting fuel. My opinion (and that is all it is) is continue focusing on your fuel non delivery problem.

As suggested, the starting fluid is a test that might confirm that the spark is working and that your problem is fuel delivery. However, be careful with that stuff. Aside from its super volatility, if you spray too much into the intake plenum it does an excellent job of washing oil off the cylinder walls. Also, if you live where the temperature doesn't drop below -20 C in the winter, you probably won't find any starting fluid for sale.

|

|

-

|

|

|

Another good reason to look at the valve train, at least the tappets for cyl #1, would be to make sure the spark is firing at the top of the compression stroke and not at the top of the exhaust stroke.

Is the #1 plug wire sitting in the forward-most distro socket?

|

|

-

|

|

|

how do i attach pics?

i wanted to attach pix of distro & the broken thermal timer; Thanks Derek, i did set fuel pressure rail to 30 as i thot a little more fuel would be better than too less,

Rob

--

Rob

|

|

-

|

|

|

To attach pix:

Go to the link below.

Scroll down about 1/2 page and hit "ADD A NEW EXHIBIT"

Provide the info it requests.

You'll probably select "Technical" from the image type pull down.

Upload the image.

It will display your image with the image HTML code the right.

Copy it and paste in your posting.

https://www.brickboard.com/GALLERY/

At least that's what works for me....

Good luck.

--

Current rides: 2005 Volvo S80 2.5T, 2003 Volvo V70 2.4NA, 1973 Volvo 1800ES (STILL not road worthy!)

|

|

-

|

|

|

so here are the pics:

first, i show the position of distributor, number pulled off and underneath its position on cap.

second shows a notch in flywheel on front, when at bottom it coincides with TDC for cyl #1 - nothing in my book references this, is this just coincidence?

thanks in advance,

https://www.brickboard.com/GALLERY/volvopic.htm?js_link=&id=13526

notch position: https://www.brickboard.com/GALLERY/volvopic.htm?js_link=&id=13527

if anyone could opine on above i would be truly grateful. I also need leads on obtaining thermal timer, or a replacement part, i ve been reading that maybe a VW part might work????

but before i start parting this out, if anyone is interested in what this ugly beast looks like that i have been bending over the best part of a year.....

https://www.brickboard.com/GALLERY/volvopic.htm?js_link=&id=13528

thanks in advance,

Rob

--

Rob

|

|

-

|

|

|

I have NOS thermal timers and a I should have a few good used ones.

But 1st you should get the car running.

Have you sourced a good used vacuum pressure sensor yet?

--

Eric

Hi Performance Automotive Service (formerly OVO or Old Volvos Only)

Torrance, CA 90502

hiperformanceautoservice.com or oldvolvosonly.com

|

|

-

|

|

|

The car refuses to start it does not even want to attempt to fire even with

tinkering with the timing. I have checked that the csv is firing as

designed.

I did not think the mps would disrupt starting I thought that it was more

of a performance item but since joining this board I have learnt otherwise.

I have not been able to source good used mps yet looking on interwebs over

weekend have seen used no guarantee units so im stuck. Someone asked where

I was. ...im in Florida

Thanks in advance rob

|

|

-

|

|

|

Rob;

OK...so you don't have enriching because of the nonfunctional CSV, but you do have fuel (in a posting way back you said Sp Plugs were wet), so I would expect at least some signs of engine life (firing)...I now have to point to and question the Ignition Timing...and "tinkering" with it is not going to help...I advise Static Timing to a definite Timing setting. See: https://www.sw-em.com/Volvo%20Ignition%20from%20Scratch.htm#Static%20Timing

...and while you're at the Distrib, I'd verify function of FI contacts there...these give Timing info to ECU to trigger Injection pulses. Pull off FI connector and check with an Ohm meter. FI troubleshooting Booklet probably has details.

...as far as what your trying to show on the pictures...I don't quite see it and I can't get it from your explanation...try again!

GH

|

|

-

|

|

|

hi Ron et al,

here is my distro pic position as requested: i have labelled number 1 now

https://www.brickboard.com/GALLERY/volvopic.htm?js_link=&id=13529

the second question i was asking was in regards to the engine position at TDC, i do not have any guide/ wheel here as my guide is missing / broken off, i bought the car like that, however i notice when i set the #1 cylinder to TDC, valves loose and shaking, distributor pointing to approx 300 degrees, there is a notch / hole that is oval shaped and it is always pointing down in the 6 o'clock position. Does this signify TDC for me as my formal reference point is missing or is that just coincidence? I do not see any reference to that mark in the manuals:

here is pic of what i am seeing, unfortunately due to size restrictions here i have to crop it, but what i m showing is the bottom of the crank wheel with the oval mark at the bottom, again marked up for easy viewing; the top of the picture just out of view is the crank wheel nut and at the bottom of pic is the drive belt,

https://www.brickboard.com/GALLERY/volvopic.htm?js_link=&id=13530

this is simple mechanics just like my old (new back in the 80's) 1971 ford escort GT, set TDC of engine with cyl 1 make sure distro pointer is pointing to 1, start up and drive, so i don't understand why i dont even get an effort to fire,

thanks in advance for your invaluable guidance,

rob

--

Rob

|

|

-

|

|

|

The timing pointer is cast into the front timing cover and it might be hard to see especially if there is a thick coating of muck on it. Check out the picture of the front timing cover on the website below.

http://212.247.61.152/us/main.aspx?page=article&artno=418693

I'm going to say it again, even if the vacuum pressure sensor holds vacuum and the resistance tests specs out, it can still be faulty and can keep the car from running.

I went through my collection of sensors and found a good used "010" that held vacuum and then I tested it on our 1971 and the car fired right up and ran.

If you want to use it as a loaner, contact me through my website's Contact page.

http://hiperformanceautoservice.com/contact_us.php

--

Eric

Hi Performance Automotive Service (formerly OVO or Old Volvos Only)

Torrance, CA 90502

hiperformanceautoservice.com or oldvolvosonly.com

|

|

-

|

|

|

thanks Eric!

i m going to do that; in the meantime do you have the a TT i can buy from you, mine is toast,

https://www.brickboard.com/GALLERY/volvopic.htm?js_link=&id=13531

Thanks in advance,

Rob

--

Rob

|

|

-

|

|

|

Hello Rob,

$75.00 for a good used tested TT or a new 1 for $200.00 plus shipping and insurance.

--

Eric

Hi Performance Automotive Service (formerly OVO or Old Volvos Only)

Torrance, CA 90502

hiperformanceautoservice.com or oldvolvosonly.com

|

|

-

|

|

|

np, i ' ll take the used one for $75, once i get a chance to test with the

loaner MPS, we will see if this thing works.

BTW, i went back and set up again per Rons instructions, i found 10 degrees

on the timing wheel set to timing mark static timed exactly

how Ron does it, i did slightly differently, cap off, ignition on and with

my tester looking for on / off blink, essentially what Rons' instructions

say less the

test light. This brought me back to exactly the same position i had before,

so i m thinking its the MPS, why would that suddenly go out but i have

learnt to never assume

with this car as it has never been 1 problem, but many layered over one

another. Now when i had everything apart for cleaning i did not plug up the

whole to the hose leading to MPS as i did not know it was so sensitive....

experience lesson learned! My dad always told me don't clean too much, once

it works leave it alone was his motto

i messaged you on your site so you have my details,

thanks all for your help to date, fascinating this one has been a real

knowledge bender so far!

Rob

|

|

-

|

|

|

I absolutely agree with Ron that you need to confirm the operation of the D jet trigger points in the base of the distributor. If those trigger points are not operating correctly the engine will definitely never run. Check them before you consider replacing the MAP sensor.

|

|

-

|

|

|

greetings All!

so i believe i confirmed this already - before i installed the injectors in the holders, i cranked and had fuel ejected in the sequence 1 & 3 , 2 & 4. Also when i m attempting to start, pulling out plugs, i confirmed all are wet as well as the cold start value ejecting fuel - it is functioning due to TT being grounded. I am currently in contact with Eric who will kindly provide replacement TT as well as loaner MPS to test,

thanks all for your help to date,

Rob

--

Rob

|

|

-

|

|

|

If the injectors are squirting during cranking, that confirms that the points in the distributor are working.

|

|

-

|

|

|

“...If the injectors are squirting during cranking, that confirms that the points in the distributor are working...”

Even if the trigger points aren’t working, if the driver pumps the throttle while cranking the engine (which he shouldn’t have to) don’t the injectors pulse 19 times per full pedal stroke as commanded by the throttle switch? If so, then the plugs could get wet regardless of whether the trigger points are functioning or not.

I prefer to spend the 2-3 extra minutes to remove the distributor to the workbench where it’s easier to connect the ohm meter and to do the trial and error thing with the trigger point gaps. Just remove the two bolts that hold the distro flange to the engine block - don’t loosen the pinch bolt that secures the ignition timing. That way you don’t have to reset the ignition timing when you reinstall the distro.

For lack of any other instruction I try to get the trigger points to about 180 degrees of dwell by tweaking the stationary side of the points - open half of the time and closed half of the time. The dwell/timing is not critical. The gaps will close up over time as the lobe followers wear down.

|

|

-

|

|

|

You are correct that opening and closing the throttle switch with the D jet powered up will cause the injectors to operate. I can't confirm the number of injections that occur; but, I believe it is specified in the D jet trouble shooting manual because opening and then closing the throttle with the system powered up is one of the test procedures set out in the manual. Confirming the number of pulses helps to verify the correct operation of one of the functions of the throttle switch. Also useful for confirming the wiring to the injectors and the throttle switch and that the controller is not completely dead.

The OP was reporting operation of the injectors while cranking. I made the presumption that he wasn't busy opening and closing the throttle at the same time. If he wasn't opening and closing the throttle, then operation of the injectors would confirm that the distributor contacts seem to be operating.

|

|

-

|

|

|

142g;

Base injection pulses are a result of contact closures from Distributor contacts. Pulses resulting from opening Throttle are from contact closures of the comb contacts in TPS, both function similarly as far as the hardware goes (both are inputs to RS Flip-Flops in ECU), but otherwise quite a different thing...and the later can work fine during tests (should be 20 pulses!), even if the former is not working...BOTH need to work for normal function and good throttle response...and complicating things further is that the TPS is not even necessary for engine to run...the MAP sensor supplies ECU with enough info with which to supply a base fuel amount, even at various Throttle openings...TPS only allows improved throttle response with quick Throttle opening...as a D-Jet experienced guy, you probably are aware of these things, I'm reiterating them here more for Rob's info...

Cheers

|

|

-

|

|

|

Rob;

I took the liberty of adjusting the Subject line...

OK...so you are now timed and have spark...please verify contact closures are being provided by Distributor to ECU!

GH!

|

|

-

|

|

|

Following with interest, unfortunately my feed of the forum doesn’t give me dates on subsequent posts, so I’m not sure of the sequence of posts and testing.

In any event I don’t think I’ve seen the results of the MPS/MAP, I.e the suction test , have you done this, is it good?

|

|

-

|

|

|

With respect to your VP injectors and poor fitting seals. Measure the diameter of the plastic fitting on the end of the injector (the part that covers the pintle). The diameter on Bosch and exact fit replacements is approximately 9.2 mm. If your injectors 'tips' are 9.2 mm, then the original style seals should fit. Some of the aftermarket seals are poor fitting; however, even good correct fitting seals are a struggle to get the injector in place and the locking collar correctly locked. Spraying the seals with silicon spray can help with the installation. I prefer to coat the seals with dielectric Permatex dielectric grease which is actually a silicon grease. Unlike spray, it doesn't run off and gives a nice long working time. It still requires a fair amount of push to get the injector in place with a new seal.

If your injector tips are 9.2 mm in diameter, then Eric can probably supply you with the correct seals. Also, Rock Auto may still sell them, IPD probably sells them and Iroll probably sells them. If the injector tips are not 9.2 mm, then I don't know what VP has sold you for a replacement injector. In such case, you may be stuck with whatever seal they provided.

I failed to notice the comment in your first post that the engine briefly fires and then dies. If the engine briefly fires while cranking and then dies when you release the ignition key to the run position, then the D jet 'MAY' be failing to make the transition from starting on the cold start injector to running on the main injectors. If this is the case, then there are a number of possible problems.

- Problems with the manifold air pressure sensor (MAP) have already been discussed. If you have done the basic tests and it has passed then that is all you can do for now. If you eliminate all the other causes you may have to come back to the MAP.

- Problems with the set of two contacts in the base of the distributor. As described in the D jet trouble shooting manual you need to insure that both contacts are opening and closing as the engine turns. When the contacts are closed make sure the resistance is low (probably 1 ohm or less after adjusting for your measurement leads). High resistance when closed can lead to flaky operation. Both sets of contacts must operate. The two contacts form the input to an electronic circuit called a toggle that switches back and forth between the two injector banks and triggers the timing for the injector duration. If one of the contacts doesn't work, the circuit hangs up on one side and nothing happens because the controller fails to get an RPM signal.

- problems with the auxiliary air regulator and the throttle position switch. You need to insure that the aux air regulator is opening and closing. If the aux air regulator does not open on a cold engine the engine will not get enough air to sustain operation. It will also make cold starts difficult. Follow the procedure in the D jet trouble shooting manual for testing the throttle switch and setting the throttle switch. Correct operation and setting of the throttle switch is critical to D jet operation.

I no longer use the D jet controller on my B20E; but, I recall that there is a test that you can perform on the D jet using the throttle switch. You turn the ignition key to the run position and then turn the throttle (and throttle switch) from the closed position to the full open position. You should hear the injectors click open and closed something like 11 or 12 times. I think the test is described in the manual and if not current D jet owners may be able to provide the specifics. If the injectors are hard to hear, you can purchase injector test lights to confirm that the injectors are getting the on-off signals.

Note that the presence of 12 volts at the injectors is not an indication that things are working. When the key is in the run position, there should always be 12 volts at the injector terminals. The controller turns the injector on by applying a ground to the unpowered side of the injector (ground switched system). The preceding test using the throttle switch (and lights if required) confirms that the wiring is good and the controller is doing its switching action.

When checking the electrical connections on the D jet, it is usually not the plug that fails. Rather, check the wiring for about 6 - 8" back from the plug. This may require cutting back and then repair of the jacket. The insulation becomes brittle with age and can flake off leading to internal shorting. This is particularly prevalent on the injector plugs and coolant temperature sensor plug which get a lot of heat exposure. The wiring to the throttle position switch is also a problem because one side of the wire is fixed on the fender and the other is attached to the engine. B20 engines vibrate and move a lot. This can lead to a lot of flexing and fractures of the wire where it plugs into the switch.

|

|

-

|

|

|

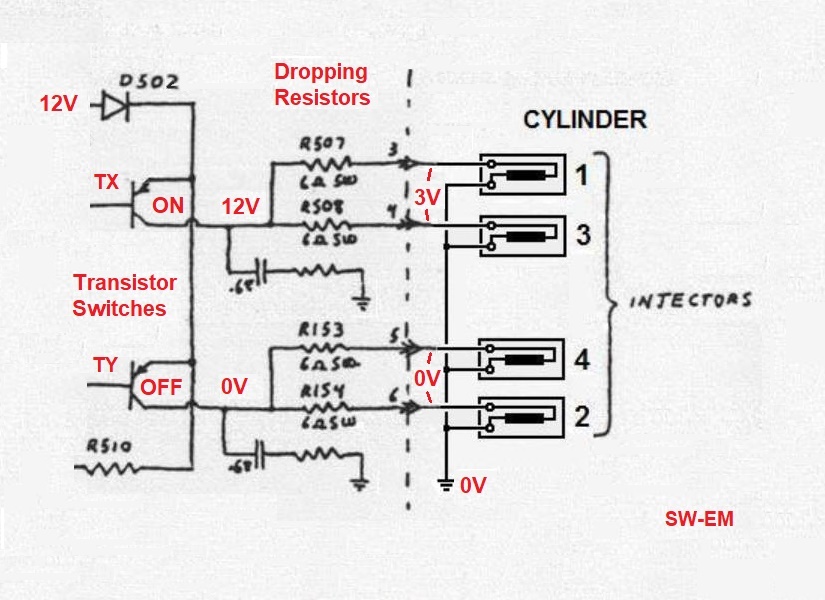

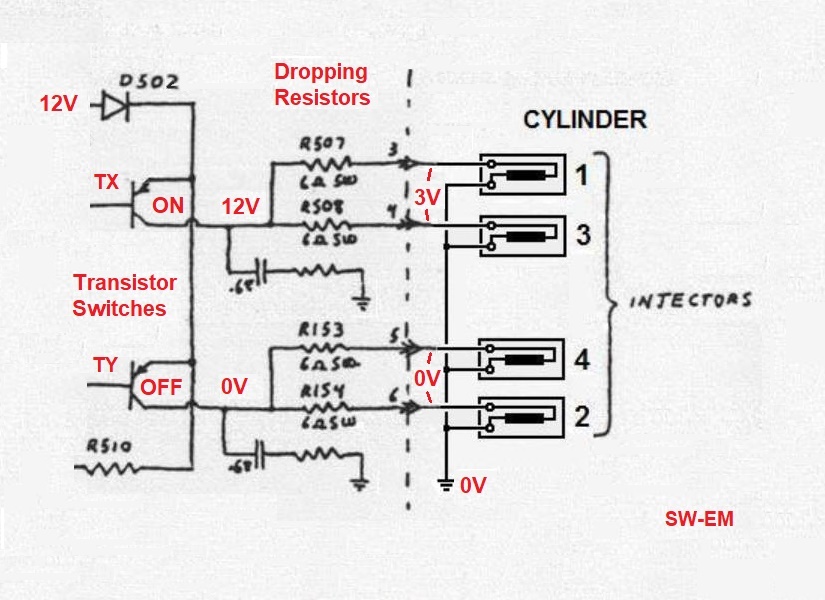

Rob;

Very good info from 142g, as usual!

I would like to add a bit to clarify about the Injector power which can be tricky to understand for non electronics guys...one side of ALL Injectors is in fact tied to chassis so you should ALWAYS read 0V there (Ref: https://www.sw-em.com/bosch_d-jetronic_injection.htm#Bosch_D-Jetronic_Circuit ), and yes, the other side of all will measure at 12V, but this is deceiving in that it measures this only when the associated transistor switch in the ECU is OPEN, and NO current is flowing through Injector (and its Pintle and fuelflow are CLOSED!)...when the transistor switch (momentarily) closes during operation, does current flow through the Injector, Pintle opens allowing fuelflow, and at that time, voltage on the side previously measured at 12V will drop to 3V as supplied voltage is divided by 6Ohm series resistor within ECU and Injector, but as this is strictly a transient condition, this can ONLY be seen on a DVM with a catch-and-hold function, or oscilloscope.

Injectors are NOT designed or intended for a full 12V...in fact, applying this voltage directly would overheat and kill an Injector short order (and guys who have applied a full 12V, even if only for test purposes, have lunched Lord knows how many like that)...DON'T DO IT!...Injector CAN be safely tested by (momentarily) applying 12V, but by way of a 6Ohm 5W limiting resistor.

One of the TPS functions can be checked with Ign ON, open Throttle and listen for 20 clicks all the way to Wide Open Throttle. Ref: https://www.brickboard.com/RWD/volvo/758191/1800/throttle_position_switch_test.html (Note: this test does NOT check adjustment!) More on TPS here (there's a lot happening in this little box!): https://www.sw-em.com/bosch_d-jetronic_injection.htm#TPS

Cheers

|

|

-

|

|

|

Mia culpa!

You are correct about the D jet configuration using a common ground on one side of all the injectors. The D jet controller uses PNP transistors with the emitter held at 12 volts and the collector connected to the injectors through 6 ohm resistors. The voltage on the non grounded side of the injector will switch from 0 volts to about 3.2 volts when turned on.

I was clearly stuck in an NPN emitter at ground / MOSFET frame of mind.

|

|

-

|

|

|

142g;

...correct of course about the PNP transistor switches in ECU, but after looking at it a while more, I realized that I actually got the theory of operation explanation slightly wrong...one would read 0V on BOTH sides of the Injectors, and only see the 3V under dynamic operating conditions with a catch-and-hold DVM or scope...

I have made a mark-up of an excerpt the Kerfoot drawing showing the output stages of ECU with voltages at Injectors under transistor ON and OFF conditions:

Cheers

Edit: I have just added this graphic, plus associated notes to the D-Jet page. See: https://www.sw-em.com/bosch_d-jetronic_injection.htm#Dynamic_and_Static_Injector_Test_Notes

|

|

-

|

|

|

“....Injectors are NOT designed or intended for a full 12V...in fact, applying this voltage directly would overheat and kill an Injector short order (and guys who have applied a full 12V, even if only for test purposes, have lunched Lord knows how many like that)...DON'T DO IT!...

OK, about now I’m feeling pretty lucky that I got away with running 12v through my injectors, albeit only applied in quick rapid clicks, while back flushing them with pressurized (~28-29 psi) carb cleaner. Oh well it worked and I was able to actually capture some dislodged particulate and get them unclogged and flowing equally. Reconnected them to the car’s fuel rail and wiring and connected clear “catch tubes”. Then I pulled the distributor out of the engine and removed the cap - left the rotor in place and trigger points connected. I may have disconnected the primary coil wiring to protect the points from frying, I don’t recall. Then I turned on the ignition to activate the pump and d- jet system. Then I turned, turned, turned the rotor with my finger as fast as I could. The catch tubes captured the injected fuel equally across all four. By simultaneously sucking on the MPS hose and propping the throttle open or closed I was able to see some variation in injector flow. No vacuum on the MPS combined with wide open throttle provides the greatest fuel flow while high vacuum on the MPS combined with closed throttle provides the least flow. I know this sounds like rather crude testing but if nothing else it provides an “indication” that the injectors, trigger points, MPS, and TPS are at least functioning somewhat like they should. Plus you may find the visual of some guy spinning the distro with one finger while sucking on a rubber hose to be somewhat entertaining.

|

|

-

|

|

|

Chris;

...yes...a visual which might stay with me a while too...we do what we have to...but your technique is actually a pretty effective "almost" normal operational test of D-Jet, including ECU, to show Injectors are flowing fuel when they should, and not leaking when they shouldn't...which is never!

Note: Applying full 12V to an injector is a mighty hard (and risky!) hit electrically, but it might just be what it takes to mechanically free up a stuck Pintle...but do this NOT many times, judiciously (very briefly ONLY!), and at your own risk!! A better technique for freeing up a stuck Pintle would be a solvent soak (I suggest carb cleaner, Marvel Mystery Oil mix), then applying 12V through a Dropping Res and momentarily, just like in normal operation!...no risk of hurting the Injector then! ...but if this does not free Pintle, I'd say OK to applying double voltage momentarily (by reducing DR to 2.5Ohms, and monitor Injector temp during tests!)...best practice is to NEVER apply a full 12V or continuous power...it's just too risky!

Cheers

|

|

-

|

|

|

That was entertaining! An innovative way of qualitatively evaluating that the MAP sensor is doing something in an approximately correct fashion (more fuel at high MAP / less fuel at low MAP). I would have personally been inclined to use something like a mityvac for the vacuum function. The whole visual of sucking on the MAP line, adjusting the throttle and turning the distributor is a visual that is going to stick with me for a while.

|

|

-

|

|

|

greetings Ron et al,

just to confirm, i am testing the triggering to injectors, 1 & 3 fire together 2 & 4?

I am confirming this because i did cut back repair the harness and it maybe possible i got inj connectors 2 & 3 mixed up. My current condition is 1 & 3 firing, then 2 & 4, apologizes if this already been pointed i searched mesg string and did not see,my book refers to 1 & 3 firing together on page 68,

Thanks in advance,

Rob

--

Rob

|

|

-

|

|

|

The arrangement as it comes from the factory is that 1&3 fire together and 2&4 fire together. Your wiring appears to be correct.

|

|

-

|

|

|

thanks so much 142!

did not want to assume even thou the firing order is 1342, ( did i mention

i ve been trying to start this tihng since Xmas? this was supposed to be a

project whilst i was off for 2 weeks over hols.

So tonight i managed to remove old CSV, tested it there is no gas, happy

with myself, i installed new one......and guess what, we have no gas upon

ignition or cranking, i can see gas making it over to CSV in my clear

tubing, now removed.

i connected both ways, still nothing, the test light gives no voltage, i

ran out of light, so more tomorrow,

Thanks ALL for valuable insight to date,

|

|

-

|

|

|

"and guess what, we have no gas upon

ignition or cranking, i can see gas making it over to CSV in my clear

tubing, now removed.

i connected both ways, still nothing, the test light gives no voltage, i

ran out of light, so more tomorrow,"

So, just to be clear, the fuel pump is priming and pressurizing the fuel rail; but, the cold start valve does not appear to be getting 12 volts when the starter is cranking? The starter needs to be cranking to get 12 volts at the CSV. If that is the case, the first thing I would do is to check the wiring on the termination plug for the CSV. If you removed and reconnected the plug a few times, the insulation may have become damaged.

The CSV is powered up by the CSV relay which is controlled by the D jet controller. You can find the relay in the schematic provided by Ron. I don't know the exact location on an 1800; but, it will be typically clustered with the main relay and the fuel pump relay. During cranking, check for 12 v on the 87 terminal of this relay. If you have 12v on the 87 terminal; but, no voltage at the CSV you have a bad connection between the relay and the CSV.

|

|

-

|

|

|

142g; "CSV is powered up by the CSV relay which is controlled by the D jet controller." ...if I understand correctly, subject vehicle is a '73ES, in which case CSI is controlled not by ECU, but by Thermo-Time-Switch, as shown here: https://www.sw-em.com/bosch_d-jetronic_injection.htm#D-Jet_in_73_1800ES (as I previously mentioned).

Rob; If CSV is being supplied by Fuelrail, but not injecting fuel, it is either not being energized OR stuck closed.

Cheers

|

|

-

|

|

|

On the 1973 1800 there should be a white wire that supplies +12v from the starter to the thermal timer. Then there should be two white wires that run from the thermal timer to the CSV providing both + and - 12v. As a CSV test both + and - jumpers can be run from the battery to the CSV. I’m not sure if polarity even matters.

|

|

-

|

|

|

so this is what i have,

removed old CSV, tested it across battery with 12 V it works, as does the new one. When i crank engine i only have 10.5 volts to wire 44 with my digital tester, with either CSV connected (fuel line on) but not installed i get no fuel ejected. Apperas 10.5V is not enough to actuate the motor in the CSV.

I disconnect and reconnect CSV's directly to battery, the residual fuel in the valve ejects......ie both valves test good.

so the question is what is causing me to lose 1.5V and how do i fix??

i do not think cause is the thermo time sensor? that is all or nothing correct?

i am thinking once i fix isse with CSV, i should get a start condition,

Thanks in advance,

--

Rob

|

|

-

|

|

|

So, having been schooled by Ron about the change in the control for the CSV, a little investigation yields this:

http://volvo1800pictures.com/document/ES73%20Wiring%20digram/73%20Wiring.jpg

the diagram shows the thermal switch controlling the cold start valve directly - no relay.

As Ron points out, if you measure the voltage at the cold start valve with the starter motor engaged, 10.5 volts would be a very acceptable voltage because of the internal drop in the battery. The cold start valve is ground switched by the thermal timer device. I think the easy test would be to apply a ground at the thermal timer to force the cold start valve on during cranking by by-passing the thermal timer. If the cold start valve operates, then it would appear that the thermal timer device is faulty. Just for added confusion, the wire numbering (33 & 34) for the thermal timer connections is reversed between the 1973 wiring diagram for the 1800E and the 1973 Djet trouble shooting manual wiring diagram. I would normally refer to wire numbers; but, Volvo seems to have had some document control issues. According to the schematics, the thermal control device has two terminals. One has 2 wires and the other 1 wire. According to the wiring diagram, the connection to ground for testing would be the terminal with 1 wire. Note that if you ground the other wire you will create a dead short with very undesirable results so getting it right is important.

There was reference to the cold start valve not operating above 55C. This appears to be the setting for the earlier system controlled by the D jet controller. The Djet trouble shooting manual indicates that the operating point for the thermal timer switch is 35 C (pg 2-19). If you are doing work on the car in really hot weather, it might be possible that even though the engine is at ambient temperature, you might be above the operating point of the thermal timer. I am also pretty sure that the device is not exactly precision so it probably has a +/- 2 deg or more tolerance). As an observation, I wonder if the 35 C is a misprint because that does seem too low to provide zero starting enrichment.

Since my advice is guided purely by conflicting wiring diagrams, I defer to the testing advice of anybody who has actually done this.

|

|

-

|

|

|

Ok so here is latest p1800 philes

So I don't have gas at the csv. When I ground single wire from thermo timer

I get spraying at the csv with 10.5 volts on the meter. The battery voltage

is fully charged and drops to 11.5 at the battery terminals when cranking.

I guess this value depends on cranks amps of battery.

With regards to pressure sensor test I get 95, 367 and Infiniti on

resistance tests. When I do suck test I got nothing as pipe appeared to

have a leak. I replaced with a new piece of half inch fuel rated tubing

upon performing again I can hear diaphagm operating with enough vacuum to

'grab' my lips.

So then I crank and crank and crank...! And not even attempting to fire

now...I was hoping I would get an attempt to start now

Any ideas folks?

Thanks in advance

|

|

-

|

|

|

As mentioned before, 1 of my parts customers in NH recently couldn't get the engine we rebuilt for him to start and his mechanics made a thorough examination and couldn't find the cause even after they tried a good used ECU I sent to them and checked all of the electrical connections.

It turned out to be the pressure sensor was damaged in a way that it wasn't capable of sending the required signal that the ECU needs to properly fire the injectors even though held vacuum and was in spec on the resistance tests. The importance of vacuum pressure sensor is is mentioned in the article from Dr D-jet that I posted a link to(Did you read it?).

When the mechanic installed a good used pressure sensor, the car fired right up even though it was the wrong pressure sensor.

Do you have a spare vacuum pressure sensor?

--

Eric

Hi Performance Automotive Service (formerly OVO or Old Volvos Only)

Torrance, CA 90502

hiperformanceautoservice.com or oldvolvosonly.com

|

|

-

|

|

|

i do not have a spare pressure sensor to test with unfortunately, i see a new one listed for $1500! I have spent well over $1000 on this thing since Jan alone - ugh!

So from my tests i gather i need a thermo timer, i looked i cannot find one online, can anyone help me with that part?

I will keep looking fr the pressure sensor.

I believe root cause of my 'unreliability' (i have driven 3 miles in 4 years!) is a culmination of old worn out injectors, fuel filter completely clogged, possibly leading to inj failure 1 or more in stuck open mode filling the crank case with gas; leaking pipe to pressure sensor and a faulty thermo timer. In case folks have missed it, this car has never started reliably even to use to go get coffee on Sunday mornings.

I believe i m pretty close now, as i have replaced coil, contact set, cap, rotor, wiring harness, leads, distributor, injectors, all gas lines and cleaned the tank out. Its difficult to diagnose when you have a multitude of issues all at the same time affecting starting & performance. I plan to replace gas tank with new once i can get it going.

If anyone can point me to or have parts to help me i would really appreciate; in the case where its something you want to keep (like press sensor) i understand but if someone could help me by lending me one to try, that would be wonderful,

Thanks as always to your very valuable info!

Rob

--

Rob

|

|

-

|

|

|

Hey,

If you going to pay $1500.00 for a new pressure sensor, would you PLEASE buy it from ME!!!

I do have a NOS 1 in stock.

But I would prefer to have yours repaired if possible as it is way cheaper. The cost to rebuild a Volvo D-Jet vacuum pressure sensor ranges from $350.00 to $500.00.

But before you do either, let's try to find you a loaner test unit so you can be sure that is the problem. I'll look and see if I have something. Remember, you can use any 1 of the 5 or 6 vacuum pressure sensors used on 140/164 Volvos to test the system.

I really hate seeing people use the parts cannon indiscriminately.

FYI, I also have new and good used thermal timers and for way less than $650.00 like the German ebay item listed below.

https://www.ebay.com/itm/Volvo-P1800-140-164-Thermozeitsensor-thermal-time-sensor-NOS-new-old-stock/223338879765?hash=item340008db15:g:8xUAAOSw8PJcRzvR

--

Eric

Hi Performance Automotive Service (formerly OVO or Old Volvos Only)

Torrance, CA 90502

hiperformanceautoservice.com or oldvolvosonly.com

|

|

-

|

|

|

Try the test described by Chris Mullet in his Aug 21 post where he watches the fuel PW change as he adjusts the vacuum on the MAP sensor. That test will give you an idea as to whether the MAP sensor is working.

|

|

-

|

|

|

We have verified with testing the way the thermal timer works.

The internal switch works like an old school turn signal flasher relay where a pair of bimetal strips makes and breaks contact as the bimetal strips cycles between cool and hot due to the heat generated while current is being applied.

When cold, the internal switch/contact inside the thermal timer passes a ground supplied by the housing of the thermal timer and it's connection to the engine block to the terminal labeled "W" on the thermal timer.

When enough current passes through the thermal timer during a cold start or when the engine is warm, the switch/contact moves and actually makes contact to the power supplied to the thermal timer via the starter motor so both contacts now get power. So if you test both contacts at the CSV, both with have positive voltage when you use the starter when the contact move to the warm position.

I have never understood why the ground switches to power and not just to an open position.

I hope I am misreading your suggestion to ground the thermal timer directly to trigger the CSV. If you ground the "W" terminal on the thermal timer that supplies the ground to trigger the CSV, you will be creating a potential short because as I stated above, both terminals will get power when it switches to the warm position. FYI, when the thermal timers fail they almost always failsafe with the internal switch contact in the warm condition so power gets supplied to both thermal timer terminals and the CSV WON'T open.

If you want to test the wiring for the CSV, then unplug the wire connected to the "W" terminal on the thermal timer and then ground just the wire and that will activate the CSV.

--

Eric

Hi Performance Automotive Service (formerly OVO or Old Volvos Only)

Torrance, CA 90502

hiperformanceautoservice.com or oldvolvosonly.com

|

|

-

|

|

|

I was going from the wiring diagram in the back of the D jet trouble shooting manual and proposing to ground what is marked as the G terminal. I was unclear in that I was proposing to ground the wire attached to the G terminal after it had been removed from the G terminal; however, based upon the diagram in the trouble shooting manual I don't think that would be necessary. However, the trouble shooting manual diagram differs from the service manual diagram, so I again defer to somebody who has actually done trouble shooting on this device.

|

|

-

posted by

someone claiming to be ROLFE

on

Fri Aug 23 07:41 CST 2019 [ RELATED]

|

|

Your 10.5v at the CSV may be an indicator of voltage loss occurring somewhere in the ignition circuit. You may want to try this:

Measure the voltage from the + terminal of the coil to ground when cranking. Should be greater than 10.5v. If not, connect a jumper from coil + to battery + and try starting. NOTE: if the car does start, you will not be able to turn it off until you disconnect the jumper. Do not leave the jumper on for a long time.

Good luck!

|

|

-

|

|

|

I've been "sort of" following this thread but hadn't had anything to add. But now that attention has been paid to the thermal timer it triggered a recollection I had of diagnosing the cold start valve not functioning. The TT screws into a brass fitting in the block. Remove the TT from the fitting and clean the threads thoroughly -- now remove the brass fitting and clean its threads thoroughly. Years ago when I worked at a Volvo "Indy" shop and saw these models on a regular basis I found on more than one occasion a poor ground at that spot to be the problem. -- Dave

|

|

-

|

|

|

Thanks Dave!

i will try this tomorrow!

cheers,

Rob

--

Rob

|

|

-

|

|

|

Rob;

I just checked the cut-way view of CSV in green manual to see if there is an internal final filter (as there is in the cyl Injectors)...my thought is that if this filter was totally clogged, even if you had Fuelrail pressure, and you applied power to CSV winding,(and it was free to operate), this filter, if clogged, could still completely impede fuelflow...result of looking in manual: ...it is not absolutely clear (and labeled as a filter like for the cyl Injectors), but it does look like there is a final filter present in the CSV also...so if you verify that TTS is supplying power to CSV and it is not flowing, this is another possible reason which could prevent fuelflow...simple fix is to blast in carb cleaner and catch what is flushed out on a white paper towel for inspection.

Good Hunting!

|

|

-

|

|

|

--000000000000d8e5df0590e39881

|

|

-

|

|

|

Good morning Ron

I replaced the old csv with a new one.I tested it it did not work until I

shorted the TT. Cranking it sprays with a great spray pattern at 10.5v on

the meter. I am in the midst of removing thermal timer cleaning it together

with the threading in block to improve ground per Rolfe.

If that does not work then it appears I would need a new thermal timer. If

I do not get start then I think I need to look at pressure sensor again. My

press sensor appears to be operating correctly I was reaserching last night

and I m getting a vacuum tool to pull gradual pressure on it and take

readings.....does anyone have experience at this i realize I need to do

this with care

Thanks in advance

|

|

-

|

|

|

Rob;

"...the question is what is causing me to lose 1.5V and how do i fix??" ...10.5V could very well be the voltage Battery is dropping to under cranking load, and this is absolutely typical and normal! Repeat test while measuring voltage at Battery to confirm. ...so when bus voltage drops like that, that is all your going to see when measuring ANYTHING else in vehicle, including FI components.

" Apperas 10.5V is not enough to actuate the motor in the CSV." I expect it should be without doubt, as this (Bat V drop during cranking) is as I said: Absolutely normal!!

"I disconnect and reconnect CSV's directly to battery, the residual fuel in the valve ejects......ie both valves test good." What do you mean by "good"?...I want to hear that when it was on Fuel Rail which was charged with fuel, and CSV was powered, it squirted fuel...!

Good Hunting!

|

|

-

|

|

|

I wonder what voltage drop you would get if you measured it right at the battery terminals while cranking the starter. Is the battery charged up real well? A LITTLE voltage drop would be expected but I don’t know how much drop is acceptable. If you took voltage measurements at the battery, then at the white wire connection at the starter, then at the thermal timer, you might be able to isolate where you’re losing it. Could be a nearly severed wire or a bad crimp job or ???

I don’t know about the “all or nothing” theory at the thermal timer. As a test you could bypass the thermal timer with a jumper straight from the starter to the CSV and then ground the other CSV contact which would essentially take the thermal timer out of the equation and then see if the CSV opens when commanded (starter cranking).

|

|

-

|

|

|

Rob;

I'm a little late to this thread as I've been away and just catching up, but I'd like to chime in...

First: Welcome to this Forum!

...very good info and recommendations already in this in thread, particularly from Eric and 142G! Also, there is much info out there on the D-Jet Inj Sys (the granddaddy of all modern FI Sys!) with which you should familiarize yourself with (unless you want to send the car to a specialist like Eric and put down your money...your choice!)...as previously mentioned, and don't take this wrong, but if you don't take the time to become at least very familiar with this system, and expect us to spoonfeed every bit of info which you SHOULD have going in, then get frustrated when sorting this out takes time (sorry, likely no instant gratification to be had here!), I question if we can help someone with such an attitude...we don't expect you to become an expert, but you must understand function of D-Jet Sensors and Actuators in order to troubleshoot! ...that said, suggested reading: http://volvo1800pictures.com/document/fuel_injection_fault_tracer/fuel_injection_fault_tracing.pdf My notes: https://www.sw-em.com/bosch_d-jetronic_injection.htm

I'd like to add some things and reiterate some others for emphasis...

...when Ign is ON, Supply pressure in Fuel Rail to Injectors, supplied by Fuel Pump and regulated by Fuel Pres Reg, MUST be 28PSI ...that constant, and the (unchanging) orifice size of Injectors is what the entire D-Jet is based on...Injector energization (opening) time is only variable which ECU controls to vary injection amount...dump FPR must have a clear return line to function as intended, and you already have learned about the 3V energization voltage of Injectors...! Also, a VERY common issue on these cars is a fuel feed restriction due to rust particles from the Tank clogging filters (I fought with this for a while on my '73 ES, as it can lead to strange symptoms!), but unless fuel restriction is complete, this is not a cause of a No-Start...(just watch for it as it is quite common!)

Fuelrail Pressure will tend to leakdown after shut-down...that's to be expected with non-new equipment!...only if this is virtually instantaneous is this an indication of a possible leak (or bypass), but if leakdown takes more than 30Sec, it's not a crisis, and certainly not the cause of a No-Start! Presuming elec and plumbing connections to Temp and Manif Sensors, and ECU (of course) are intact, you must have enrichment by Cold Start Valve to enable starting (note that '73 ES had the later, ECU INdependent, Thermo Time Switch controlling CSI. Here, the ECU is NOT in charge of enrichment! See: https://www.sw-em.com/bosch_d-jetronic_injection.htm#D-Jet_in_73_1800ES )...and I must accept you stating that Ign Sys is working and timed correctly...

Have you pulled Spark Plugs after No-Start...are they wet or dry?

Absolutely correct info on Dielectric grease by 142g (Kudos, and thanks for getting it right and spreading the word!) Electrical connections of sensors and everything having to do with the D-Jet (and the rest of Elec Sys for that matter!) should be Clean (meaning shiny metal!) and tight (whether push-on or bolted connection!). Loose the Dielectric grease(!) and apply Anti-Corrosive Zinc Paste on all connections (except Hi-V ign) AFTER cleanup and during reassembly/reconnection. See: https://www.sw-em.com/anti_corrosive_paste.htm The only place I don't recommend it for is the Throttle Posit Sensor. See: https://www.sw-em.com/Deoxit_D5_Additional.htm#TPS_Maintenance

Eric; Caution! (I respect your input and experience greatly, but must raise an objection here): ...the high pressure fuel-line which is supposed to be used with the D-Jet system has internal reinforcement which if crushed (even if only temporarily, to stop fuel flow for test purposes) will damage it!...I recommend against this...yes, it is a pain to disconnect and plug fuel lines (and GREAT care must be taken, and Fire Precautions exercised, with the possible squirt of fuel from a line which is holding those 28PSI. BEWARE ROB!!!), but internally damaged Fuel Line is not a good thing as they can leak without warning!...then there is a fuel leak fed by high pressure...that's double badness!

Eric and 142g; I've heard that the source of raw fuel getting into crankcase can be a leaking CSI...have you heard of any other sources?...it sounds like this should be one of the first things to concentrate on...if not, scored cyl walls due to lack of lube will surely increase the scope of the project...

That's it for now Rob...please keep us informed of your progress and findings, and we'll try to keep you from getting distracted by non-critical things, and pointed in the right direction!

Good Hunting

|

|

-

|

|

|

Hello Ron,

I sometimes forget to mention special tools and there are special tools for safely pinching fuel hoses without damaging them.

I use the Blue point/Snap-on version of pliers pictured below.

These or any pliers should NEVER be used on the later style of hard plastic fuel hose used on the K-jet/CIS fuel system. Pinching those will permanently crush them.

--

Eric

Hi Performance Automotive Service (formerly OVO or Old Volvos Only)

Torrance, CA 90502

hiperformanceautoservice.com or oldvolvosonly.com

|

|

-

|

|

|

Eric;